System and method for adjusting heat exchange area of heating surface of boiler economizer to ensure safe flue gas temperature of scr

A heat exchange area and regulating system technology, applied in heat exchange equipment, preheating, feed water heaters, etc., can solve problems such as catalyst side reactions, reduce catalytic activity, etc., to change heat exchange area, ensure normal operation, and increase temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

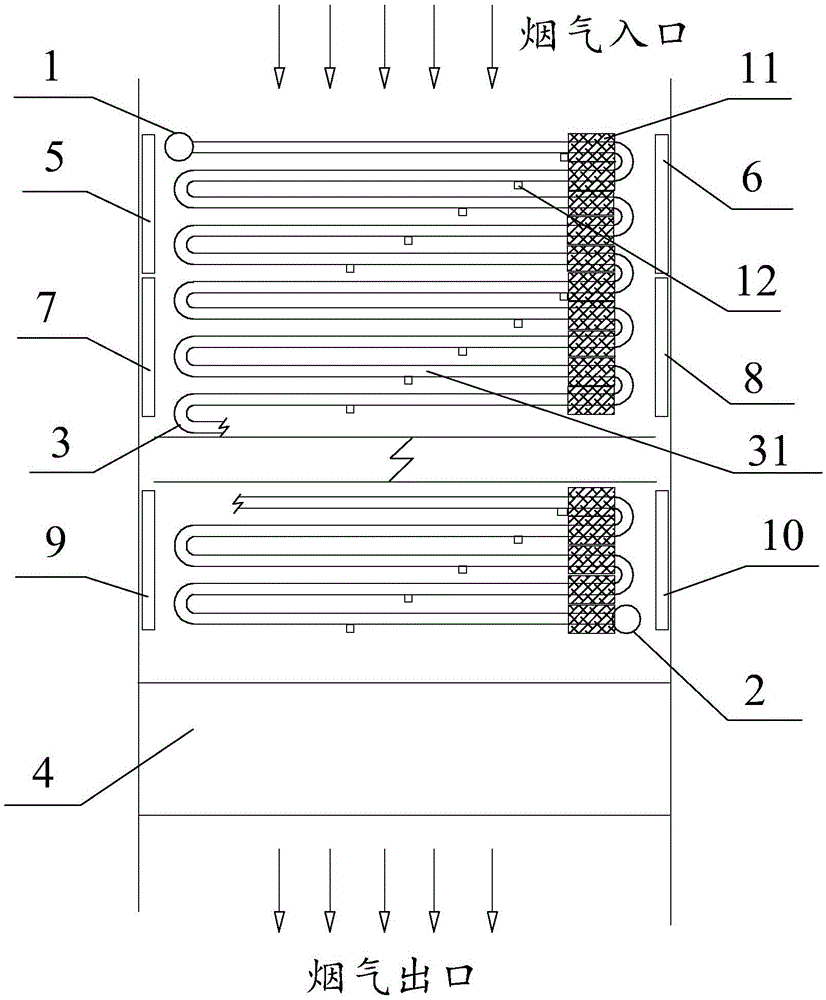

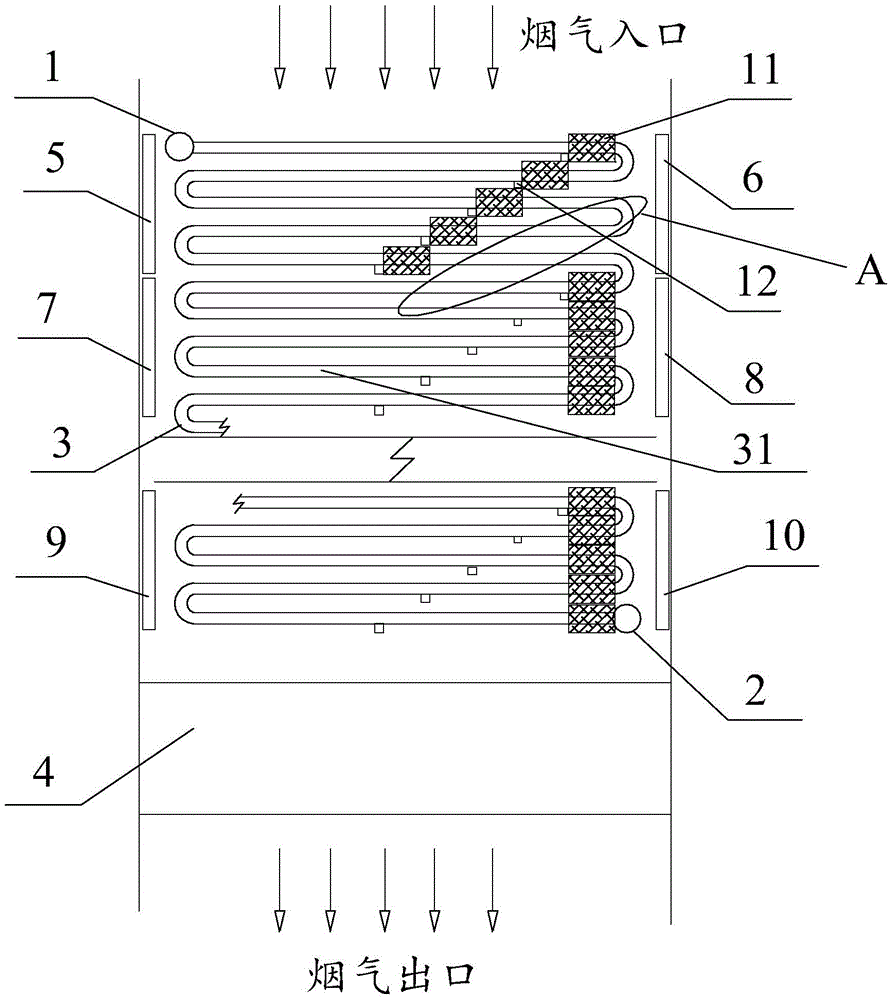

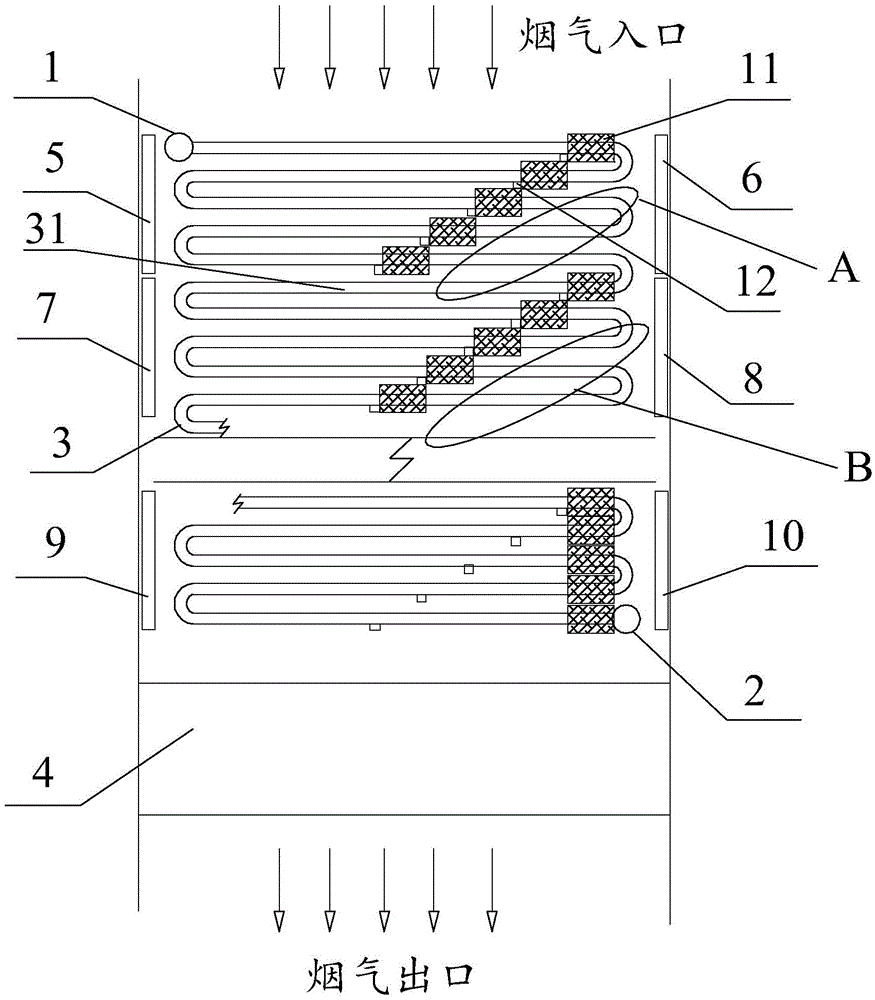

[0029] like Figure 1 to Figure 5 The shown adjustment system for the heat exchange area of the boiler economizer heating surface to ensure the SCR safe flue temperature, the boiler can be all types of boilers, the economizer 3 is installed in the tail flue of the coal-fired power plant, and the economizer 3 comes out. The flue gas enters the SCR denitration system 4 . The adjustment system includes several electromagnets, iron sliders 11 and limit pins 12 and a switch cabinet, and a control device is arranged in the switch cabinet.

[0030] In this embodiment, the electromagnet, the iron slider 11 and the limit pin 12 are set in a complete set, the electromagnet is a cuboid, the iron slider 11 is a cuboid, and the iron slider 11 has a slider hole 11a for enclosing the straight pipe section 31, The length a of the iron slider 11 is 15cm, and the electromagnets are symmetrically attached to the front and rear walls of the 3-tube panel of the boiler economizer. Each electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com