Advanced process control optimizing system of thermal power unit

An advanced process control and thermal power unit technology, applied in electrical program control, general control system, control/regulation system, etc., can solve the problem of long overheating time of main steam temperature, large fluctuation range of key parameters, long optimization work debugging period, etc. problem, to achieve the effect of improving load response rate, improving large lag, reliability and upgrading ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] The present invention provides an advanced process control optimization system for a thermal power unit aiming at the existing problems of low load response rate, large fluctuation range of key parameters, long main steam temperature overheating time, large lag and long optimization work debugging cycle.

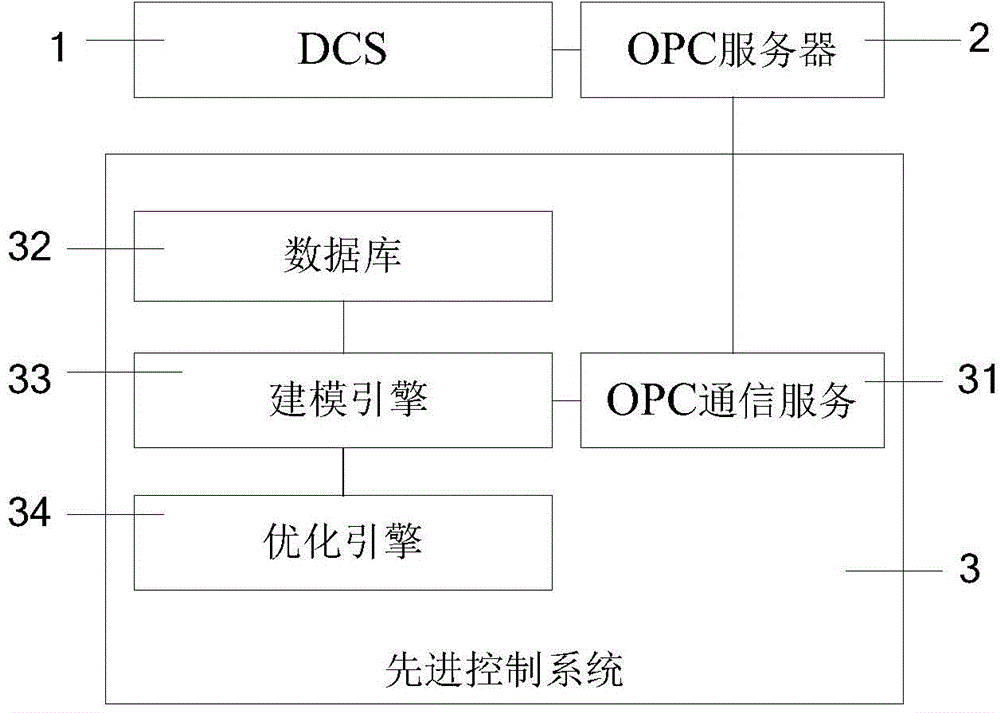

[0032] Such as figure 1 Shown is a schematic structural diagram of an advanced process control optimization system for a thermal power unit provided by an embodiment of the present invention, the system includes a discrete control system (Distributed Control System, DCS) 1 and object linking and embedding (Object Linking and Embedding) for process control for Process Control, OPC) server 2, also includes an advanced control system using predicti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com