Special compound feed for largemouth bass and preparation method of special compound feed

A compound feed and largemouth bass technology, applied in animal feed, animal feed, applications, etc., can solve the problems of unstable quality of chilled trash fish, high feed coefficient of chilled trash fish, and no breakthrough progress, etc., to achieve enhanced Improve the body's immunity, improve the ability to resist stress and disease, and avoid waste of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

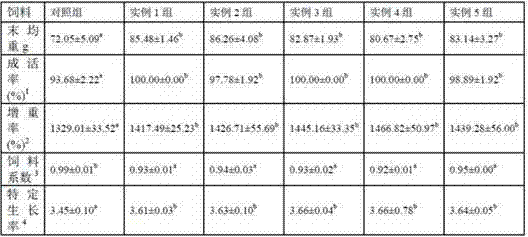

Examples

Embodiment 1

[0019] A practical extruded compound feed suitable for the entire breeding cycle of largemouth bass, which includes the following components in parts by weight: 7 parts of wheat, 12 parts of flour; 20 parts of soybean meal; 5 parts of corn gluten flour; fish meal: 30 parts; Meat and bone meal 12 parts; hydrolyzed fish protein: 4 parts; fish oil 5 parts; soybean oil 1 part; multivitamins: 0.9 parts; compound mineral salts: 0.5 parts; choline chloride (50%) 0.6 parts; vitamin C: 0.2 parts; vitamin E: 0.02 parts; methionine: 0.15 parts; lysine: 0.2 parts; inositol 0.15 parts; salt: 0.2 parts; After fully mixing the raw materials with a small amount (less than 1 part), they are used as small material additives. All other solid raw materials mentioned above need to be crushed in advance and passed through an 80-mesh sieve, and then mixed according to the above formula ratio. It is fully stirred and mixed together with the small feed, and the special extruded feed for largemouth...

Embodiment 2

[0021] An artificial compound feed suitable for the entire breeding cycle of largemouth bass, including the following components in parts by weight: 7 parts of wheat, 11 parts of flour; 20 parts of soybean meal; 6 parts of corn gluten meal flour; 28 parts of fish meal; meat and bone meal 12 parts; hydrolyzed fish protein: 5 parts; fish oil 6 parts; soybean oil 1 part; multivitamins: 0.9 parts; compound mineral salts: 0.5 parts; choline chloride (50%) 0.8 parts; Vitamin C: 0.15 parts; Vitamin E: 0.015 parts; Methionine: 0.2; Lysine: 0.2; Inositol 0.15 parts; Salt: 0.2 parts; After fully mixing the raw materials with a small amount (less than 1 part), they are used as small material additives. All other solid raw materials mentioned above need to be crushed in advance and passed through an 80-mesh sieve, and then mixed according to the above formula ratio. It is fully stirred and mixed together with the small feed, and the special extruded feed for largemouth bass is obtaine...

Embodiment 3

[0023] An artificial compound feed suitable for the entire breeding cycle of largemouth bass, including the following components in parts by weight: 6 parts of wheat, 12 parts of flour; 22 parts of soybean meal; 4 parts of corn gluten meal; 32 parts of fish meal; 10 parts of meat and bone meal hydrolyzed fish protein: 4 parts; fish oil 4 parts; soybean oil 1 part; multivitamins: 0.9 parts; compound mineral salts: 0.5 parts; choline chloride (50%) 0.6 parts; C: 0.2 parts; Vitamin E: 0.02 parts; Methionine: 0.1 parts; Lysine: 0.1 parts; Inositol 0.15 parts; Salt: 0.3 parts; Antioxidant: 0.05 parts; After fully mixing the raw materials with a small amount (less than 1 part), they are used as small material additives. All other solid raw materials mentioned above need to be crushed in advance and passed through an 80-mesh sieve, and then mixed according to the above formula ratio. It is fully stirred and mixed together with the small feed, and the special extruded feed for lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com