Bark shredder

A crusher and bark technology, applied in the direction of grain processing, etc., can solve the problems of uneven particle size, particle structure damage, increased production costs, etc., and achieve the effect of moderate size, easy operation, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

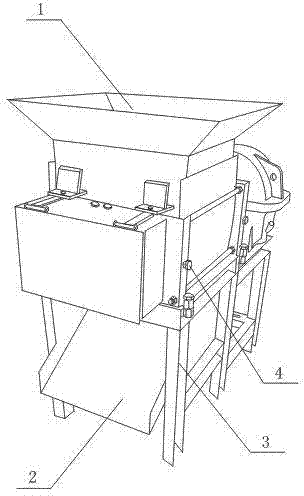

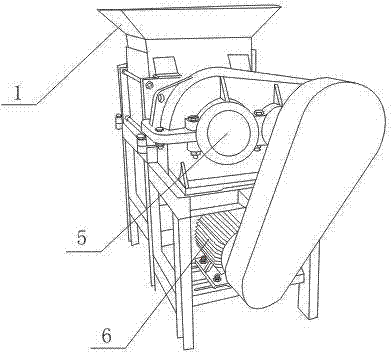

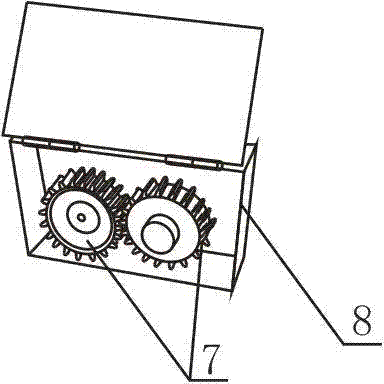

[0027] Such as figure 1 , 2 , shown in 3, a kind of bark breaker, it comprises frame 3 and the feed hopper 1 that is installed on the frame, crushing roller device, discharge port 2, motor 6 and speed reducer 5, described feed hopper 1 is located above the crushing roller device, and the discharge port 2 is located below the crushing roller device. The motor 6 and the reducer 5 are connected through a pulley and a belt drive, and the reducer 5 is connected to the crushing roller device. The crushing roller device consists of Two roller shafts 11 and a number of toothed discs 12 evenly spaced on the two roller shafts are formed, the toothed discs 12 on the two roller shafts 11 are arranged alternately, and the ends on the same side of the two roller shafts 11 pass through the gears 7 Mutual meshing transmission conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com