Novel single-mass vibrating screen

A single-mass, vibrating screen technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of increased screen surface length, excess power, unsatisfactory treatment effect, etc., and achieve high-efficiency vibration reduction and noise reduction effect, screening Effects of ability enhancement and separation effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is further described:

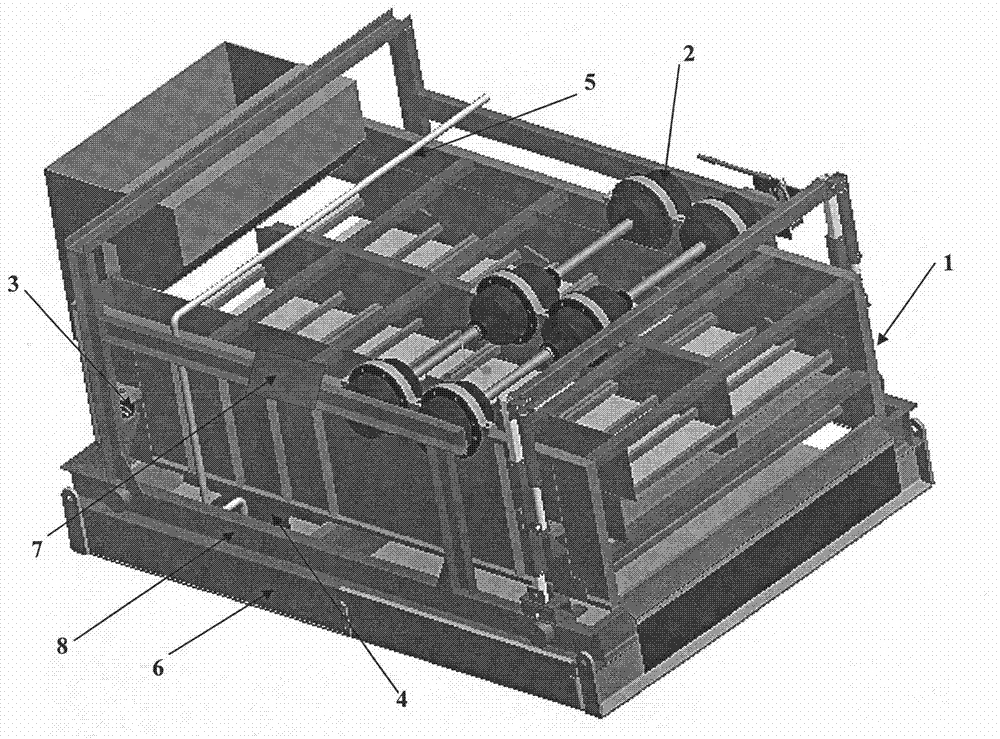

[0018] like figure 1 , figure 2 As shown, the new single-body vibrating screen consists of a single-body ultra-wide multi-layer screen box 1, a split-type large-span vibrator installed in a plug-in type 2, a silicone oil damping spring 3, and mud return devices 4 and 5 , energy-saving and life-prolonging automatic control hardware and software system 7 and the base of the whole machine 8 and other main components. The one-piece large-span vibrator 2 is installed on the upper edge of the side plate of the screen box 1 in a plug-in type, and the micro-pump 4 of the mud back-excitation device is installed in the header box 6 of the base 8 of the whole machine, and the mud back-excitation device The guide pipe 5 with the high-pressure nozzle is installed on the support of the base 8 of the whole machine and is located above the screen, and the energy-saving and life-prolonging a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com