Investment casting method of aluminum alloy pores

A technology of investment casting and aluminum alloy castings, which is applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of cumbersome process, high cost, and increased cost, so as to reduce manufacturing costs, enhance connection strength, increase The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

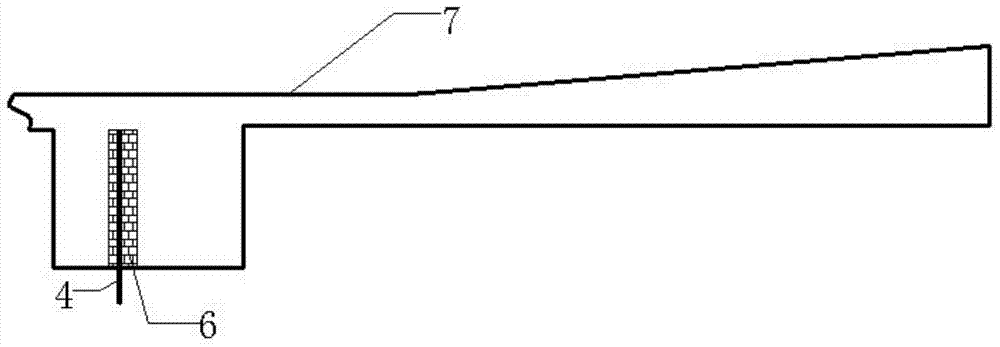

[0017] Refer to the attached figure 1 , 2 3. To further describe the technical solution of the present invention, it should be understood that the protection scope of the present invention is not limited to the following description.

[0018] Take the investment casting method of an aluminum alloy casting with fine holes as an example.

[0019] An investment casting method for aluminum alloy pores, comprising the following steps:

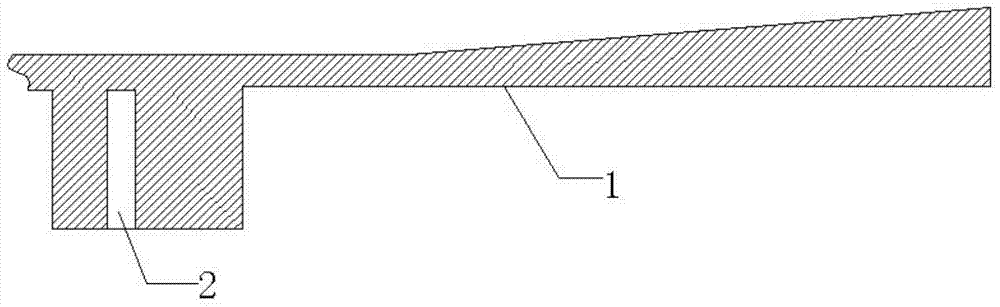

[0020] (1) Press the wax mold. Pressed through a wax mold to obtain the attached figure 1 The wax pattern 1 shown has pores 2 on the wax pattern 1, and the diameter of the pores is 5mm.

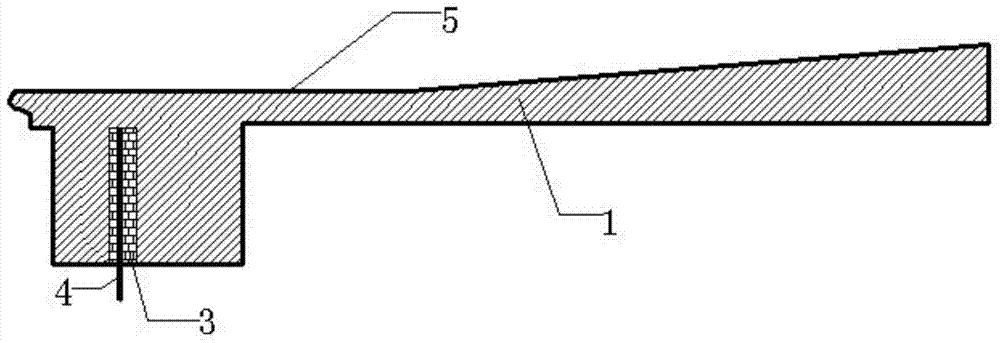

[0021] (2) Fill the pores 2 with ceramic slurry until completely filled. The ceramic slurry comprises 10 parts by weight of 30% silica sol, 8-10 parts by weight of 320-mesh white corundum powder and 0.5 part by weight of 60-mesh mullite sand, and the coarser white corundum powder helps to strengthen the ceramic core After drying, finer mullite sand is benefic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com