Numerical controlmolding clamp and molding method for medium/small caliber planar optical component

An optical part, small diameter technology, applied in the field of CNC molding fixture and molding, can solve problems such as insufficient adsorption force, optical parts burst, increase fixture manufacturing cost, etc., to solve the problem of easy sliding and falling off, increase friction coefficient, and improve molding accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

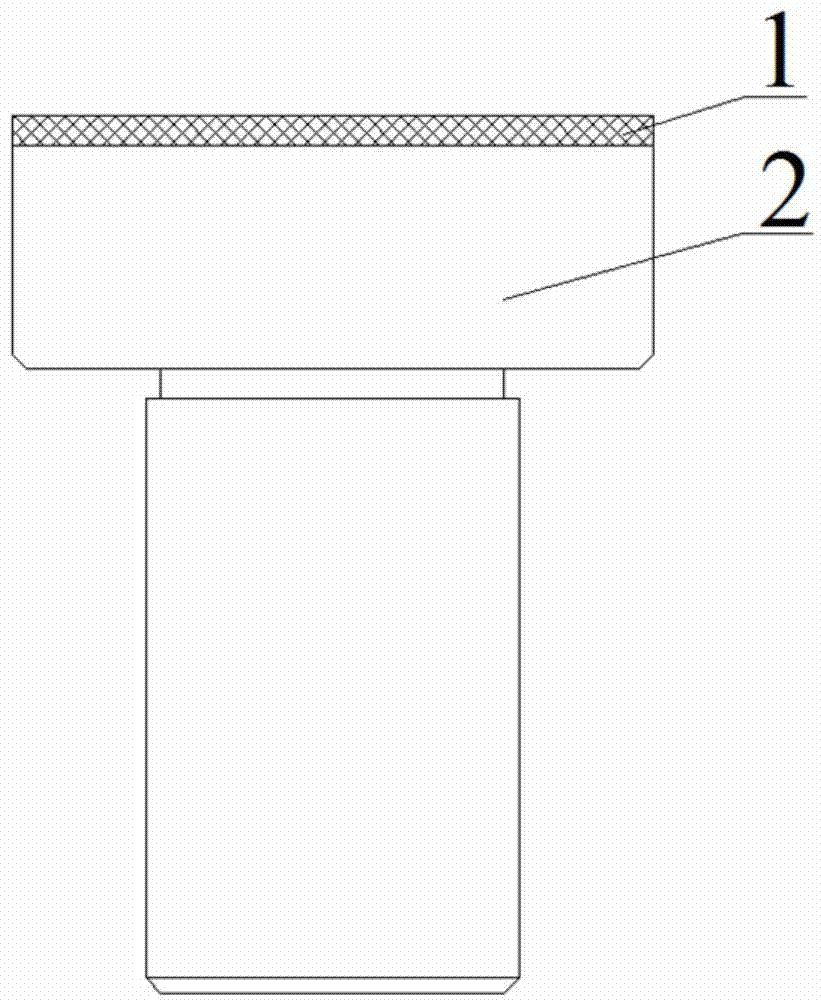

[0029] The schematic diagram of the numerical control molding fixture structure of the small and medium-caliber planar optical parts of this embodiment is as follows figure 1 As shown, the numerical control forming fixture includes a protective pad 1 and a fixture seat 2 .

[0030] Specifically, the fixture seat 2 includes a connection head connected to the machine tool spindle at the lower end and a clamping head at the upper end for effectively clamping the optical parts. The connection head is a cylindrical solid formed by precision turning; The diameter of the circle should be greater than the diameter of the connecting head, and the lower end surface is perpendicular to the axis of the connecting head; the upper end surface of the clamping head is circular or similar in shape to the clamped surface of the planar optical part; when the upper end surface of the clamping head When it is circular, its diameter is smaller than the diameter of the inscribed circle of the clampe...

Embodiment 2

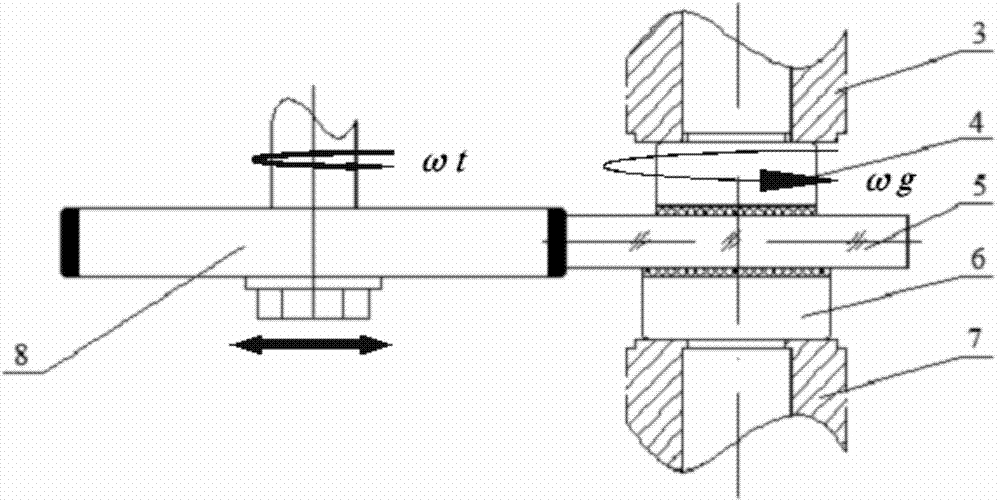

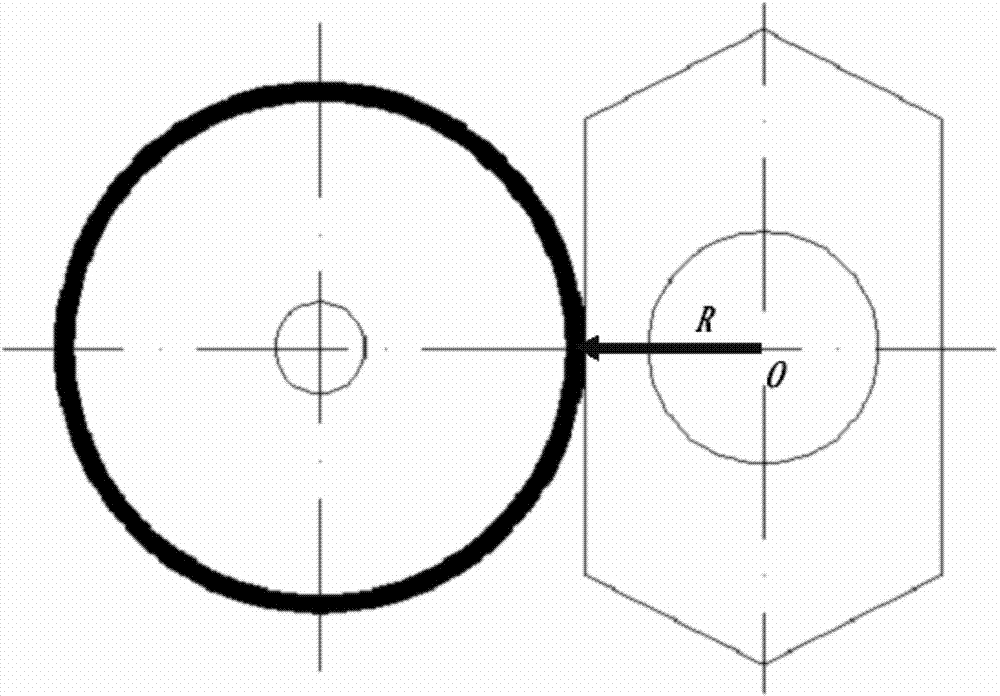

[0034] Embodiment 2 is a method of precisely numerically-controlled forming a flat optical part on a numerically-controlled edging machine using the jig described in Embodiment 1. Such as figure 2 As shown, the method for processing a flat optical part 5 from a circular blank into a required hexagon, the specific steps are as follows:

[0035] a. Turn on the machine tool, and fix the upper fixture 4 and the lower fixture 6 matching the surface size of the clamped part into the upper spindle base 3 and the lower spindle base 7 of the numerical control equipment respectively;

[0036] b. Place the blank of the planar optical part 5 on the protective pad of the lower fixture 6 to find the correct position, set and adjust the upper fixture 4 to move down and press the planar optical part 5 to an appropriate pressure; wherein, the method of finding the alignment adopts the table method Or use the grinding wheel to directly hit the positioning method.

[0037] c. Data input progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com