Automatic liquid filling machine

An automatic filling and liquid technology, which is applied in liquid bottling, liquid treatment, liquid materials, etc., can solve the problems of large space for installation and use, cannot be popularized and used by small enterprises, and large models, so as to achieve high production efficiency , simple structure, high degree of safety and sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

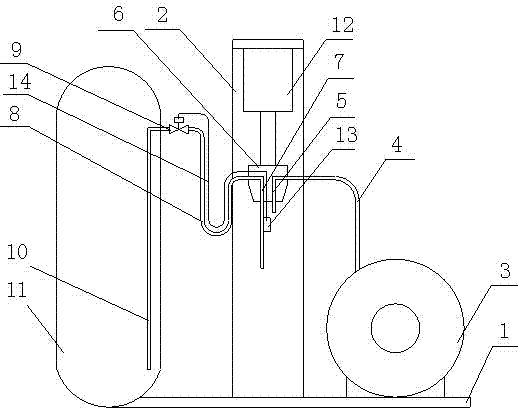

[0014] Such as figure 1 A liquid drug filling device shown includes a base 1, a bracket 2, a vacuum pump 3 and a liquid storage bottle 11, the base 1 is fixedly connected to the bracket 2, the base 1 is provided with a vacuum pump 3, and the vacuum pump 3 is connected to the exhaust pipe through the vacuum tube 4 5. The suction pipe 5 is connected to the cork 6, the cork 6 is connected to the liquid outlet pipe 7, the liquid pipe 7 is connected to the hose 8, the soft 8 pipe is connected to the valve 9, the valve 9 is connected to the suction pipe 10, and the liquid suction pipe 10 is connected to the liquid storage The bottle 11, the top of the bottle stopper 6 is connected to the lifter 12, the lifter 12 is fixedly connected to the bracket 2, and the liquid level sensor 13 is fixed on the liquid outlet pipe 7, and the liquid level sensor 13 is connected to the valve 9 through the signal line 14, and the valve 9 is electronically controlled Automatic valve, simple in structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com