Special early-strength polycarboxylate superplasticizer for prefabricated parts and preparation method of special early-strength polycarboxylate superplasticizer

A technology of early-strength polycarboxylic acid and water-reducing agent, which is applied in the field of concrete admixtures, can solve the problems of poor concrete shrinkage effect and complicated process production, and achieve low slump retention, simple process, and early strong performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

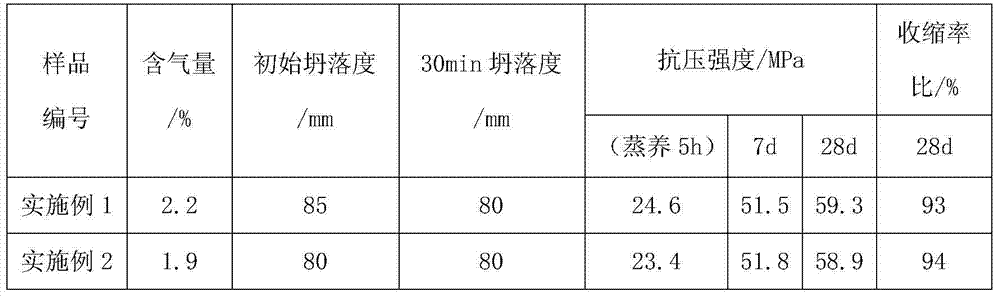

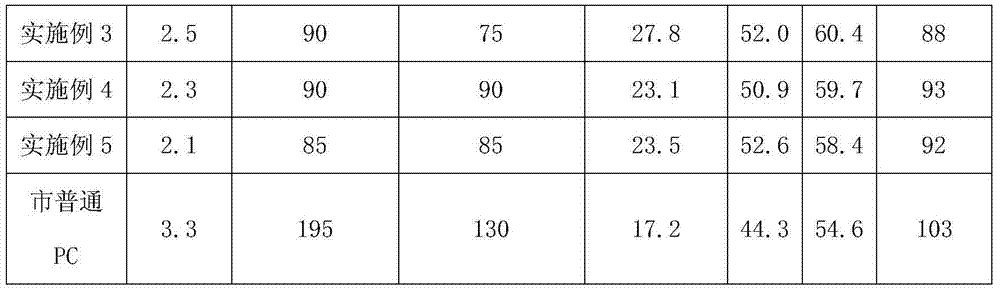

Embodiment 1

[0028] Put 1 mol of isopentenyl polyether, 0.5 mol of dimethyl fumarate and 130 mol of deionized water into a reaction flask, raise the temperature, and stir at 70°C to completely dissolve the reactants, then drop into the container Solubilize 1.25mo of l2-acrylamido-methylpropanesulfonic acid, 3.4mol of polypropylene glycol monoacrylate and 1.5mol of deionized water in water, 0.15mol of ammonium persulfate solution and 0.1mol of mercaptoethanol , Control the rate of addition, finish dropping within 3h, keep the temperature for 1 hour. After cooling, add 30% sodium hydroxide solution to adjust the pH to 6.5 to obtain a 50% solid early-strength polycarboxylate high-performance water reducer.

Embodiment 2

[0030] Put 1 mol of isopentenyl polyether, 0.4 mol of dimethyl fumarate and 100 mol of deionized water into a reaction flask, raise the temperature, stir at 65°C to completely dissolve the reactants, and then drop into the container 1.5 mol of 3-acrylamidophenylboronic acid, 3 mol of polypropylene glycol monoacrylate and 1.5 mol of deionized water, 0.2 mol of ammonium persulfate solution and 0.35 mol of sodium allyl sulfonate were dissolved, Control the rate of addition, finish dropping within 3 hours, and keep the temperature for 1 hour. After cooling, add 30% sodium hydroxide solution to adjust the pH to 6.5 to obtain a 50% solid early-strength polycarboxylate high-performance water reducer.

Embodiment 3

[0032] Put 1 mol of isopentenyl polyether, 0.5 mol of dimethyl fumarate and 100 mol of deionized water into a reaction flask, raise the temperature, stir at 60°C to completely dissolve the reactants, and then drop into the container 1.0 mol of methylol acrylamide, 4 mol of polypropylene glycol monoacrylate and 1.5 mol of deionized water are dissolved with 0.35 mol of ammonium persulfate solution and 0.4 mol of sodium methallyl sulfonate, Control the rate of addition, finish dropping within 3 hours, and keep the temperature for 1 hour. After cooling, add 30% sodium hydroxide solution to adjust the pH to 6.5 to obtain a 50% solid early-strength polycarboxylate high-performance water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com