Preparation method of cobalt ferrite magnetostrictive material

A technology of magnetostrictive materials, cobalt ferrite, applied in the field of preparation of cobalt ferrite magnetostrictive materials, can solve the problems such as cobalt ferrite magnetostrictive materials that have not yet been seen, and achieve the reduction of magnetostrictive excitation field , cost reduction, and the effect of low magnetostrictive excitation field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a cobalt ferrite CFO1, which specifically includes the following steps:

[0027] 1) Prepare cobalt oxide and iron oxide according to the atomic ratio Co:Fe=1:2, put them into a ball mill, and mix at 400r / min for 10h to obtain a uniformly mixed powder, pass through a 100-mesh sieve, and the final powder particle size is 100-200μm;

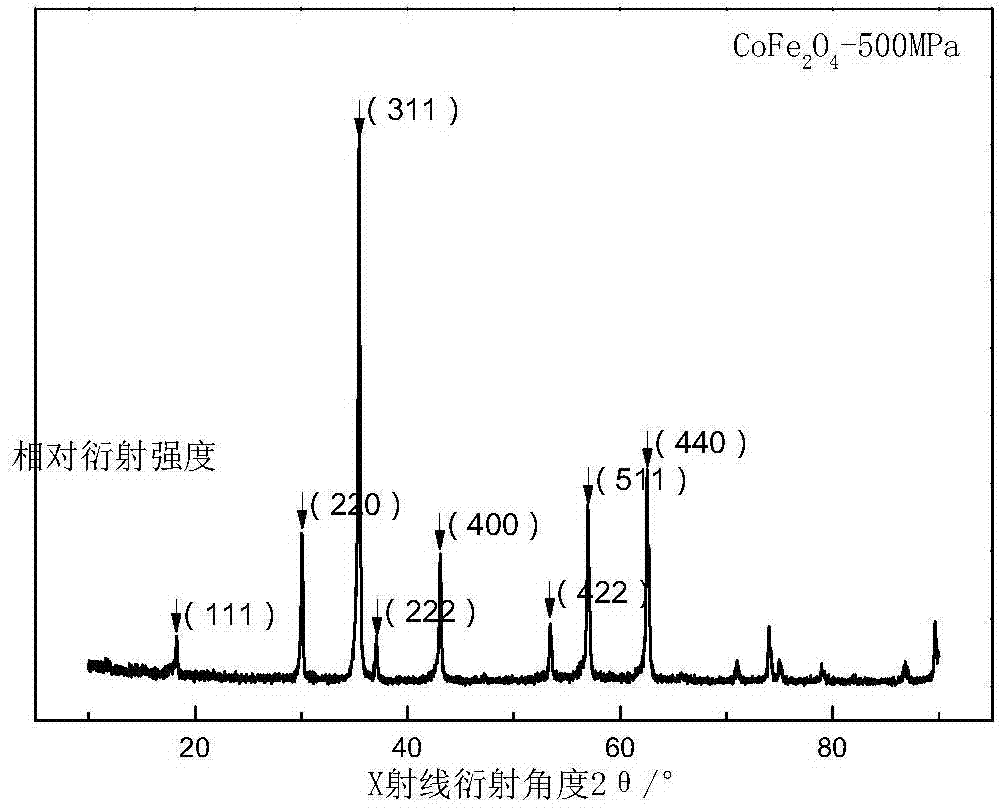

[0028] 2) The powder is formed by unidirectional compression molding, the pressing pressure is 500MPa, and the pressure is kept for 30s to obtain a prefabricated green body;

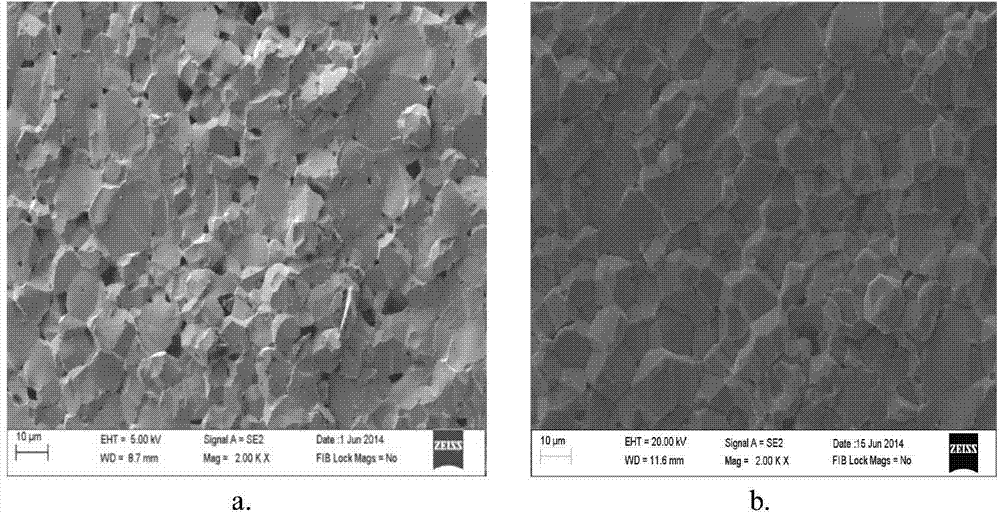

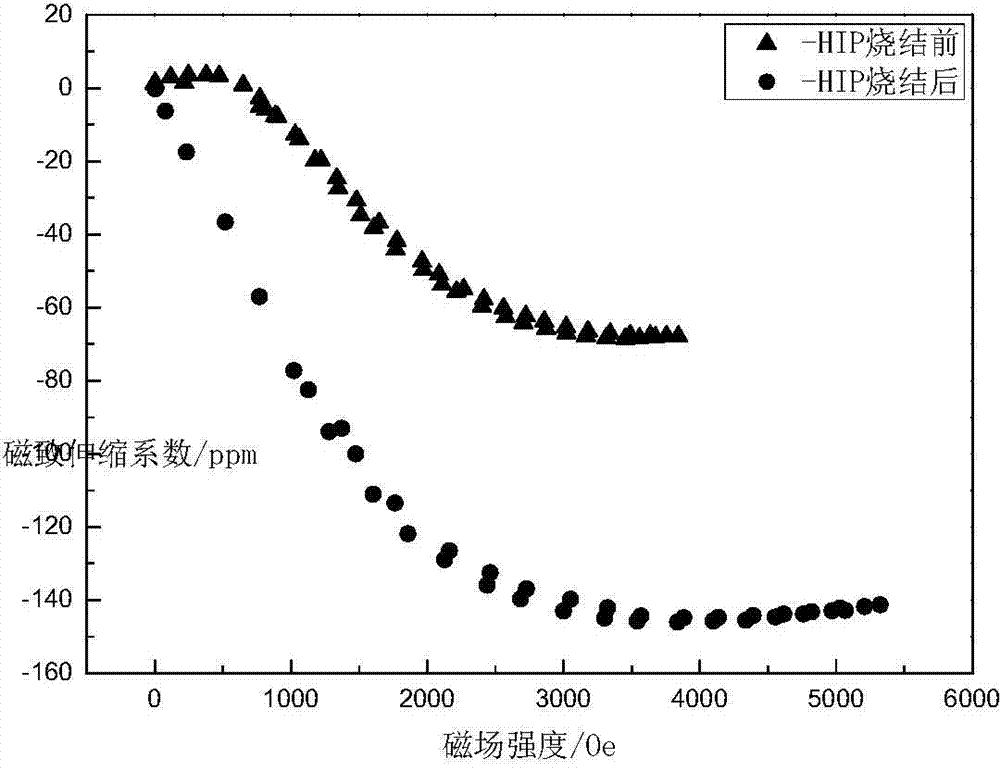

[0029] 3) Carry out atmospheric pressure sintering on the prefabricated green body, the sintering temperature is 1350 ℃, keep warm for 10 hours, and obtain the preliminary densified sample;

[0030] 4) Hot isostatic sintering is performed on the preliminary densified sample, the pressurized medium is argon, the sintering temperature is 1100° C., the pressure is 150 MPa, and the pressure is maintained for 3 hours to obtain a densified sample.

...

Embodiment 2

[0033] The present embodiment provides a kind of cobalt ferrite CFO2, specifically comprises the following steps:

[0034] 1) Prepare cobalt oxide and iron oxide according to the atomic ratio Co:Fe=1:2, put them into a ball mill, and mix at 400r / min for 10h to obtain a uniformly mixed powder, pass through a 100-mesh sieve, and the final powder particle size is 100-200μm;

[0035] 2) The powder is formed by unidirectional compression molding, the pressing pressure is 100MPa, and the pressure is maintained for 30s to obtain a prefabricated green body;

[0036] 3) Carry out atmospheric pressure sintering on the prefabricated green body, the sintering temperature is 1350 ℃, keep warm for 10 hours, and obtain the preliminary densified sample;

[0037] 4) Hot isostatic sintering is performed on the preliminary densified sample, the pressurized medium is argon, the sintering temperature is 1100° C., the pressure is 150 MPa, and the pressure is maintained for 3 hours to obtain a densi...

Embodiment 3

[0040] The present embodiment provides a kind of cobalt ferrite CFO3, specifically comprises the following steps:

[0041] 1) Prepare cobalt oxide and iron oxide according to the atomic ratio Co:Fe=1:2, put them into a ball mill, and mix at 600r / min for 10h to obtain a uniformly mixed powder, pass through a 100-mesh sieve, and the final powder particle size is 100-200μm;

[0042] 2) The powder is formed by cold isostatic pressing, and a rubber sleeve is used as a mold for forming, and the pressing pressure is 150 MPa, and the pressure is maintained for 15 minutes to obtain a prefabricated green body;

[0043] 3) Carry out atmospheric pressure sintering on the prefabricated green body, the sintering temperature is 1350 ℃, keep warm for 10 hours, and obtain the preliminary densified sample;

[0044] 4) Hot isostatic sintering is carried out on the pre-densified sample, the pressurized medium is argon, the sintering temperature is 1200° C., the pressure is 150 MPa, and the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap