Manufacturing method of dry-pressed anisotropic ferrite magnetic powder

A ferrite magnetism and manufacturing method technology, applied in the direction of inorganic material magnetism, can solve the problems of difficult mixing of adhesives and lubricants, affecting the appearance and magnetic performance, affecting the uniformity of magnetic powder, etc., and achieving good performance consistency , Conducive to mass production, improve the effect of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

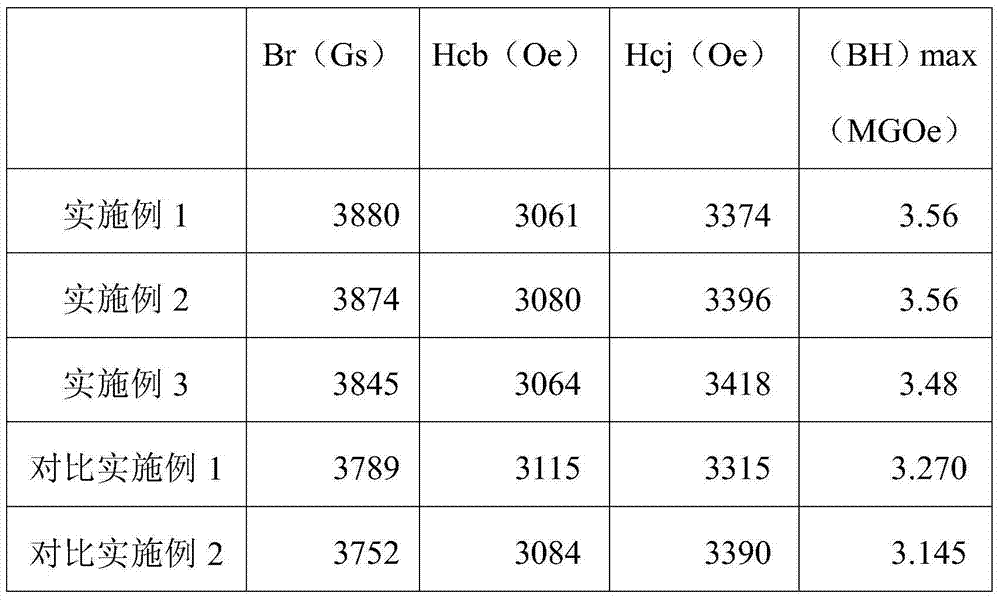

Examples

Embodiment 1

[0025] The permanent magnet ferrite calcined material includes hexagonal ferrite containing A, R, B and Fe, and has the molecular formula of the following characteristics: A 1~x R x [(Fe 3+ a Fe 2+ b ) 12-y B y ] z o 19 , where A represents one or two elements of Sr and Ba; R represents at least one element selected from rare earth elements and Bi, and must contain La; B represents Co, Ti, Mn, Zn, Ge, As and At least one element in W must contain Co, and the valence of the Co element is positive trivalent; wherein a+b is equal to 1; z is preferably 0.9 to 1.1; a is preferably 0.97 to 0.999, and b is preferably 0.001 to 0.03; The preferred ranges of x and y mentioned above are: 0≤x≤0.54, 0≤y≤0.45, and the optimal values of x, y, z are preferably: 1.0≤x / y≤1.5, and z is 1.

[0026] The specific process of dry pressing anisotropic ferrite magnetic powder is as follows:

[0027] 1. Ball milling process

[0028] Firstly, the pre-fired permanent magnet ferrite is subject...

Embodiment 2

[0038] Except milling process, all the other processes are identical with embodiment 1. Among them, the milling process is as follows:

[0039] 3. Milling process

[0040] The material piece after drying, passes through 20 mesh sieves earlier, makes magnetic powder; Then camphor and alcohol are mixed with the ratio of (1.5 grams: 1 milliliter), make solution; Then this solution and magnetic powder are mixed with (1 Milliliter: 5 grams), mix the solution and the magnetic powder evenly by spraying, and put it into a drying box and dry it at a temperature of 80 degrees Celsius for 1 hour to obtain the mother powder; finally, the mother powder and the magnetic powder are re- Mix in a ratio of 1:10, add 0.5wt% calcium stearate (through a 100-mesh sieve), mix in a dry mixer for 1 hour, and then pass through a 40-mesh sieve through a high-speed pulverizer to obtain dry-pressed heterosexual iron Oxygen powder.

Embodiment 3

[0042] Except milling process, all the other processes are identical with embodiment 1. Among them, the milling process is as follows:

[0043] 3. Milling process

[0044] The material piece after drying, passes through 20 mesh sieves earlier, makes magnetic powder; Then camphor and alcohol are mixed with the ratio of (1 gram: 1.5 milliliters), make solution; Then this solution and magnetic powder are mixed with (1 Milliliter: 6 grams), the solution and the magnetic powder were evenly mixed by spraying, and put into a drying oven to dry for 1 hour at a temperature of 80 degrees Celsius to obtain the mother powder; finally, the mother powder and the magnetic powder were re- Mix in a ratio of 1:7, add 0.5wt% calcium stearate (through a 100-mesh sieve), mix in a dry mixer for 1 hour, and then pass through a 40-mesh sieve through a high-speed pulverizer to obtain dry-pressed heterosexual iron Oxygen powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com