Binder for silicon carbide ceramic online reaction joint and preparation method thereof

A silicon carbide ceramic and binder technology, applied in the field of silicon carbide ceramics, can solve the problems of adsorption, difficult processing of the green body, voids in the bonding layer, etc., so as to reduce the bonding effect, avoid sintering deformation, and ensure fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare ingredients according to the following ratio:

[0038] Water 31.34%, polyacrylamide 6.07%, polyvinylpyrrolidone 1.48%, silicon carbide micropowder 38.43%, silicon powder 15.95%, carbon powder 6.76%. Among them, the mass ratio of silicon carbide powder with a particle size of 5 μM to silicon carbide powder with a particle size of 30 μM is 1.5:1; such a ratio can achieve good accumulation.

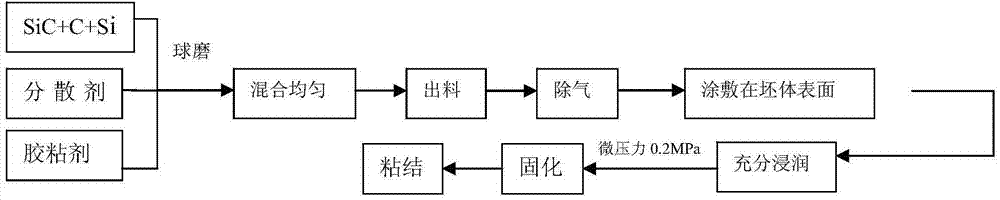

[0039] A method for preparing a bonding agent for online reaction connection of silicon carbide ceramics, comprising the following steps:

[0040] (1) Add water into polyacrylamide, stir to make it fully dissolved, then add polyvinylpyrrolidone to configure polyacrylamide solution;

[0041] (2) adding Si powder and silicon carbide micropowder into the polyacrylamide solution in turn to form a slurry;

[0042] (3) Then, ball mill the slurry for 20 hours to obtain a binder.

[0043] A method of using a bonding agent for online reaction connection of silicon carbide ceramics t...

Embodiment 2

[0048] Prepare ingredients according to the following ratio:

[0049] Water 25%, polyacrylamide 5%, polyvinyl alcohol 1%, silicon carbide micropowder 45%, silicon powder 16%, carbon powder 8%. Among them, the mass ratio of silicon carbide powder with a particle size of 10 μM to silicon carbide powder with a particle size of 40 μM is 2:1;

[0050] A method for preparing a bonding agent for online reaction connection of silicon carbide ceramics, which is basically the same as that of Example 1, except that: ball milling for 15 hours;

[0051] A method of using a bonding agent for online reaction connection of silicon carbide ceramics to carry out online reaction connection of silicon carbide ceramics, which is basically the same as in Example 1, except that: in step (1), dry at 110°C for 5 hours; step (2) ) and sintered at 1450°C for 1 hour.

Embodiment 3

[0053] Prepare ingredients according to the following ratio:

[0054] Water 35%, polyacrylamide 7%, polyvinylpyrrolidone 2%, silicon carbide micropowder 30%, silicon powder 20%, carbon powder 6%.

[0055] Among them, the mass ratio of silicon carbide powder with a particle size of 1 μM to silicon carbide powder with a particle size of 20 μM is 1:1;

[0056] A method for preparing a bonding agent for on-line reaction connection of silicon carbide ceramics, which is basically the same as that of Example 1, the difference being: ball milling for 25 hours;

[0057] A method of using a bonding agent for online reaction connection of silicon carbide ceramics to carry out online reaction connection of silicon carbide ceramics, which is basically the same as in Example 1, except that: in step (1), dry at 130°C for 3 hours; step (2) ) and sintered at 1550°C for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com