Colour master batch with low combustion speed

A technology of burning rate and color masterbatch, applied in the field of plastic coloring, to achieve the effect of excellent dispersion performance and small mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

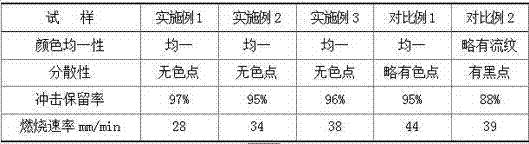

Examples

Embodiment 1

[0018] Under normal temperature and pressure, it consists of the following components by weight percentage: 10% titanium dioxide, 1% silicone oil, 1% amino silicone oil, 1% fluoropolymer PTFE, 5% dioctadecyl pentaerythritol diphosphite, Novolac resin with a softening point of 105°C 10%, 8000 mesh magnesium hydroxide 10%, bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate 0.5%, phosphate ester RDP 5 %, phosphate ester PX220 5%, ABS 35%, ASA 16.5% carry out high-speed mixing in a high-speed mixer for 10 minutes, adopt a twin-screw extruder to carry out melt blending, extrude, pelletize, dry, pack, and obtain low Burn rate masterbatches.

Embodiment 2

[0020] Under normal temperature and pressure, it is composed of the following components by weight: 10% pigment red, 0.2% carbon black, 10% silicone resin SFR100, 10% novolac resin with a softening point of 90°C, AS 39.8%, ASA 30% Perform high-speed mixing in a high-speed mixer for 4 minutes, use a twin-screw extruder for melt blending, extrude, pelletize, dry, and package to obtain a low-burning rate masterbatch.

Embodiment 3

[0022] Under normal temperature and pressure, it is composed of the following components by weight percentage: phthalocyanine blue 3%, solvent black 0.01%, phosphate ester BDP 10%, phosphate ester RDP 10%, phosphate ester SPD 10%; silicone oil 3%, ABS in Mix at a low speed in the mixer for 2 minutes, melt and blend with a twin-screw extruder, cool, crush, and then extrude with a single screw, pelletize, dry, and package to obtain a low-burning rate masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com