Composite enzymolysis process for cubilose

A processing technology and compound enzymatic hydrolysis technology, applied in the field of bird's nest processing, can solve the problems such as the relationship between the extraction process and the taste and flavor of the product is not explained, not mentioned, the influence and the yield are not mentioned, etc., to avoid adverse effects, Good swelling, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

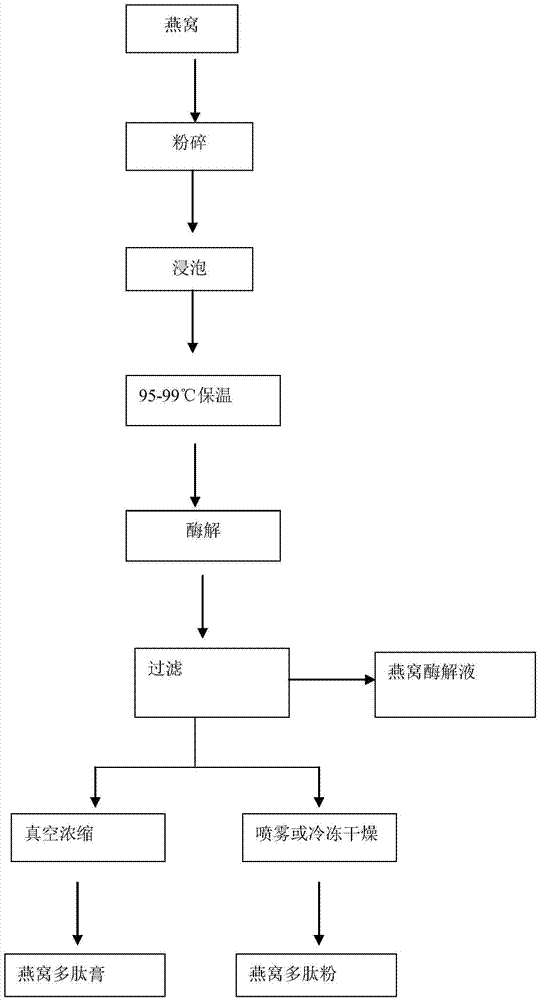

Image

Examples

Embodiment 1

[0029] Weigh 1 kg of bird’s nest and dry it, mechanically crush it through an 80-mesh sieve, add 25 kg of water to soak for 5 hours, heat it to 96 ° C for 50 minutes, cool it to 55 ° C, add 200,000 IU of neutral protease, 150,000 IU of animal protease, 20,000 IU flavor enzymes, the addition amount is 0.2%, 0.3%, 0.1%, the enzymolysis time is 6 hours, the enzymolysis pH value is the natural pH value 7.2, filtered through 100 mesh, freeze-dried, and crushed again to get bird’s nest polypeptide powder not yet. After testing, the sialic acid content of bird's nest characteristic index is 10.5%, the total number of bacteria is 460cfu / g, and the molecular weight of the product is Mn5.83*10 3 , Mw1.89*10 4 , Good water solubility, the flavor has the protein flavor of bird's nest, no bitterness.

Embodiment 2

[0031] Weigh 1 kg of bird’s nest and dry it, mechanically crush it through a 100-mesh sieve, add 30 kg of water to soak for 3 hours, heat it to 96 ° C for 60 minutes, cool it to 50 ° C, add 200,000 IU of neutral protease, 100,000 IU of animal protease, 30,000 IU flavor enzymes, the addition amount is 0.3%, 0.5%, 0.1%, the enzymolysis time is 6 hours, the enzymolysis pH value is 7.5, 100 mesh filter, freeze-dried, and crushed again to get bird’s nest polypeptide powder not yet. After testing, the sialic acid content of bird's nest characteristic index is 11.2%, the total number of bacteria is 166cfu / g, and the molecular weight of the product is Mn4.95*10 3 , Mw1.68*10 4 , Good water solubility, the flavor has the protein flavor of bird's nest, no bitterness.

Embodiment 3

[0033] Weigh 10kg of bird’s nest and dry it, mechanically crush it through an 80-mesh sieve, add 300kg of water, heat it to 99°C and keep it for 70 minutes, cool it to 60°C, add 400,000 IU of neutral protease, 100,000 IU of animal protease, and 20,000 IU 0.3%, 0.3%, and 0.1% of flavor enzymes added, the enzymolysis time was 5 hours, the enzymolysis pH value was 7.8, filtered through 100 mesh, freeze-dried, and crushed again to obtain bird’s nest polypeptide powder. After testing, the sialic acid content of bird's nest characteristic index is 11.5%, the total number of bacteria is 580cfu / g, and the molecular weight of the product is Mn5.12*10 3 , Mw1.74*10 4 , Good water solubility, the flavor has the protein flavor of bird's nest, no bitterness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com