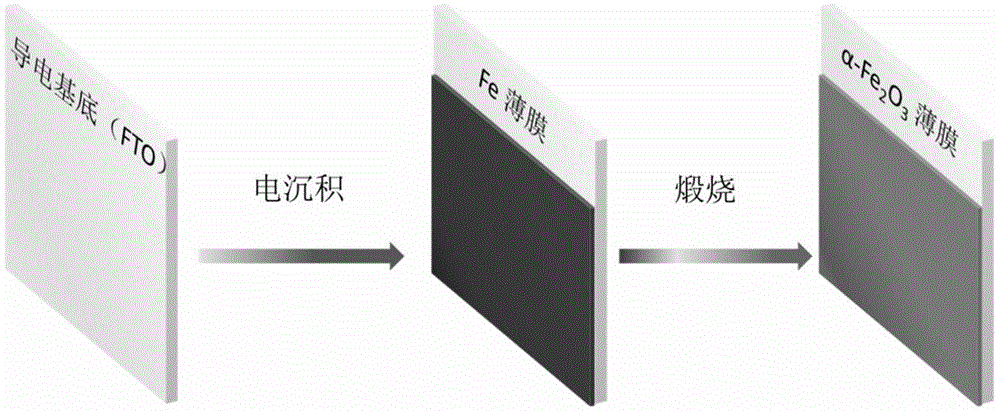

Preparation Technology of Nano-α-Fe2O3 Thin Film Electrode Responsive to Visible Light

A technology of thin film electrode and preparation process, which is applied in the field of nanomaterials, can solve the problems of fast formation of oxide layer, influence on the photoelectrocatalytic performance of thin film electrode, difficulty in controlling the thickness of oxide layer, etc., achieve good effect, good visible light absorption performance, good The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

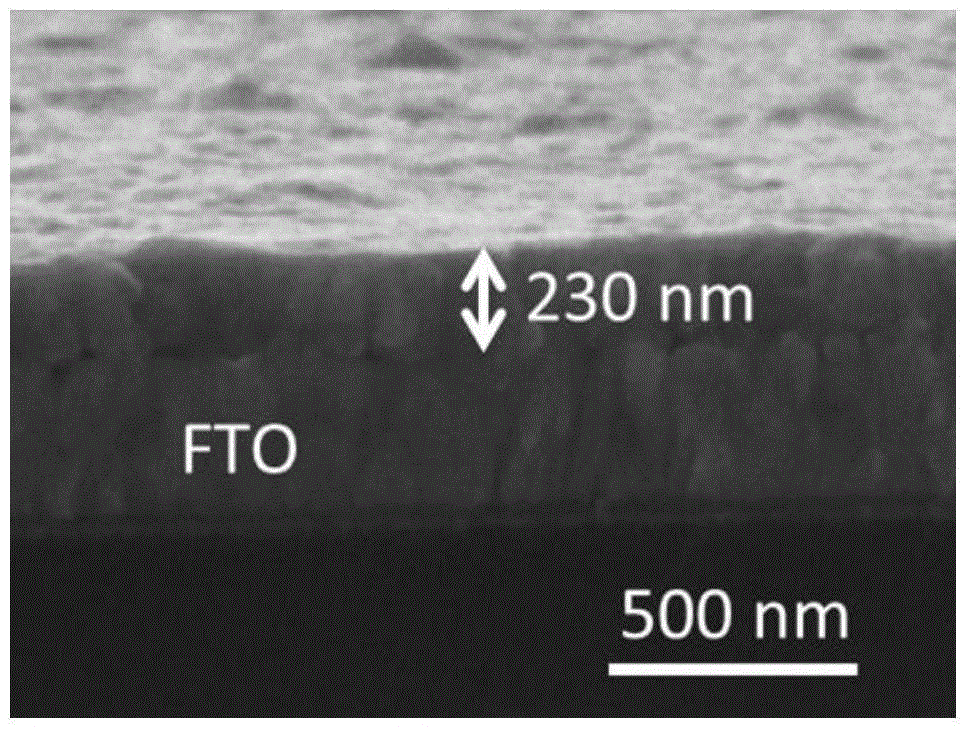

Embodiment 1

[0042] First, 5g FeSO 4 ·7H 2 O was dissolved in 150mL deionized water, then 30mL of 27% ammonia water was added thereto and vigorously stirred to obtain an electrolyte solution, the cleaned fluorine-doped tin oxide conductive glass (FTO) was placed in the electrolyte solution, and the negative electrode of the stabilized power supply connected to each other, with a platinum electrode as the counter electrode, adjusting the voltage to 2V, electrodepositing for 30s, taking out the FTO on which the Fe film was deposited, rinsing it with deionized water, and drying it at about 50°C for 1 hour to obtain the Fe film; then The Fe thin film was placed in a muffle furnace and sintered at a high temperature of 500 °C for 2 h, then naturally cooled to room temperature to obtain nano-α-Fe 2 o 3 thin film electrodes.

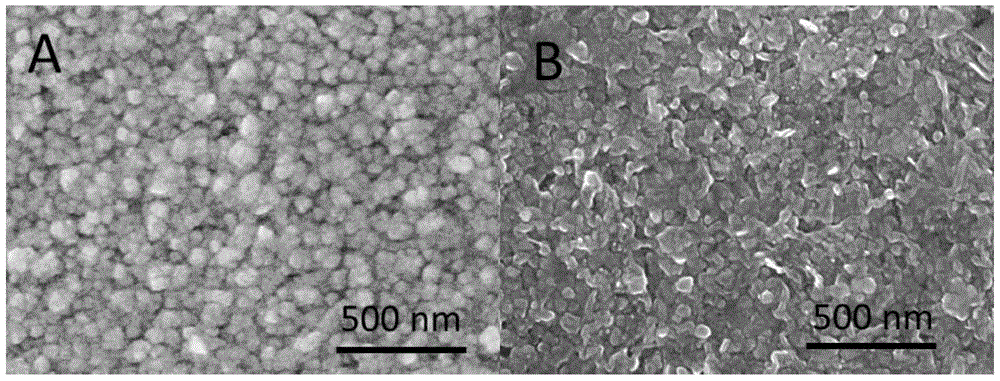

[0043] figure 2 Among them, A shows the surface micro-morphology of the Fe thin film, and its surface is uniform granular, and B shows the nanometer α-Fe 2 o 3 The s...

Embodiment 2

[0051] First, 2g FeSO 4 ·7H 2 O was dissolved in 150mL deionized water, then 20mL of 27% ammonia water was added thereto and vigorously stirred to obtain an electrolyte solution, the cleaned fluorine-doped tin oxide conductive glass (FTO) was placed in the electrolyte solution, and the negative electrode of the stabilized power supply connected to each other, with a platinum electrode as the counter electrode, adjusting the voltage to 2.5V, electrodeposition for 60s, taking out the FTO with the deposited Fe film, washing it with deionized water, drying it at about 50°C for 1 hour to obtain the Fe film, and then depositing the Fe film The above-mentioned Fe thin film is placed in a muffle furnace and sintered at a high temperature of 700 ° C for 1.5 h, and then naturally cooled to room temperature to obtain nano-α-Fe 2 o 3 thin film electrodes. The α-Fe 2 o 3 The film is pure α-Fe 2 o 3 , with a thickness of about 410nm.

Embodiment 3

[0053] First 8g FeSO 4 ·7H 2 O was dissolved in 150mL deionized water, and then 50mL of 27% ammonia water was added to it and vigorously stirred to obtain an electrolyte solution. The washed FTO was placed in the electrolyte solution, connected to the cathode of the regulated power supply, and a platinum electrode was used as the counter electrode , adjust the voltage to 1.5V, electrodeposit for 15s, take out the FTO with the deposited Fe film, rinse it with deionized water, dry it at about 50°C for 1 hour to obtain the Fe film, and then place the Fe film in the muffle After being sintered at 400°C for 6 hours in a furnace, it was naturally cooled to room temperature to obtain nano-α-Fe 2 o 3 thin film electrodes. The α-Fe 2 o 3 The film is pure α-Fe 2 o 3 , with a thickness of about 180nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com