Half-externally-surrounded building type cast-in-place wall self heat-insulation system combined with heat insulation and preservation coatings

A self-insulation system, thermal insulation technology, applied in thermal insulation, walls, building materials, etc., can solve the problems of poor rainwater leakage resistance, poor fire safety, and poor fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

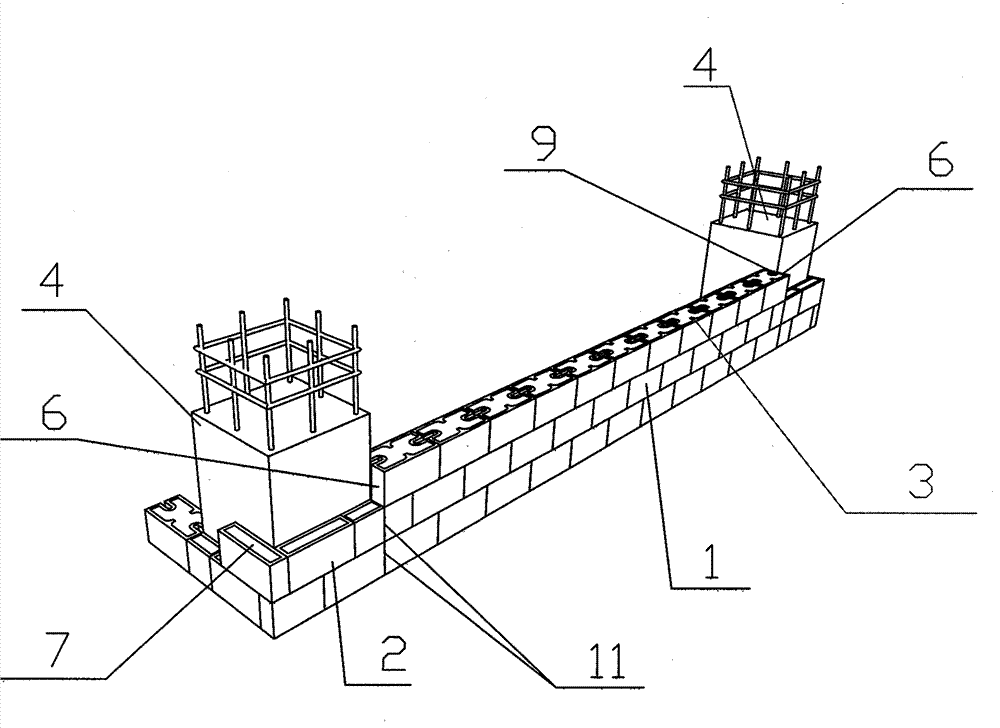

[0079] Such as figure 1 , Figure 4 As shown, a thermal insulation coating and semi-outsourcing cast-in-place wall self-insulation system is characterized in that the thermal insulation coating and semi-outsourcing cast-in-place wall self-insulation system includes A-type composite thermal insulation blocks Self-insulation wall (1), B-type composite insulation block self-insulation wall (2), oblique brick self-insulation wall and beam insulation, self-insulation walls on both sides of the window, and cast-in-place at the top of the window and the top of the wall Self-insulation wall, lintel insulation body on the upper part of the door frame; the specific method and structure are as follows:

[0080] (1) The method and structure of the A-type composite thermal insulation block self-insulation wall (1): use the A-type composite thermal insulation block (3) to build the A-type composite thermal insulation block self-insulation wall (1), and the A-type composite thermal insulati...

Embodiment approach 2

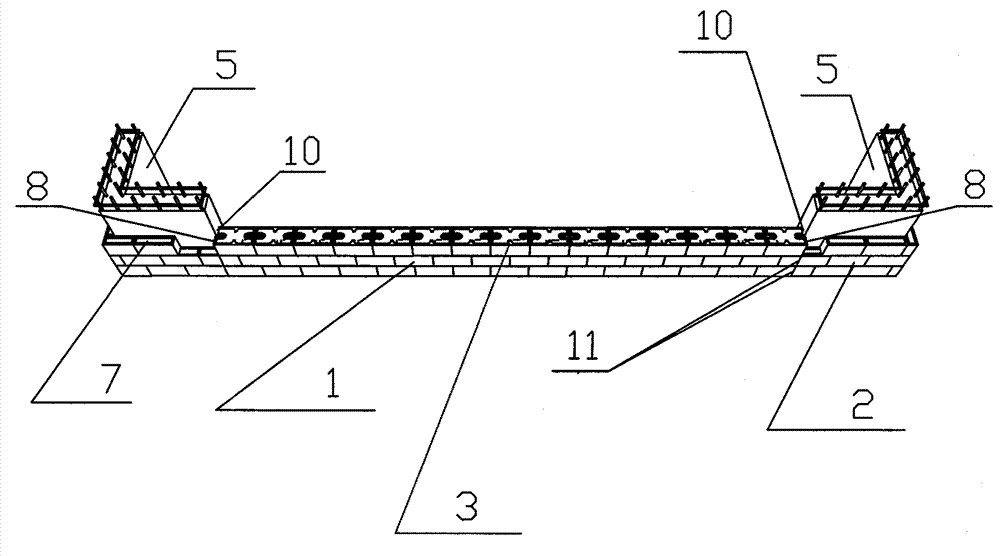

[0091] Such as figure 2 , Figure 5As shown, a self-insulation system of a semi-outsourcing cast-in-place wall is characterized in that the thermal insulation coating and the semi-outsourcing cast-in-place wall self-insulation system include an A-type composite thermal insulation block self-insulation wall ( 1), B-type composite thermal insulation block self-insulation wall (2), oblique brick self-insulation wall and beam insulation body, self-insulation wall on both sides of the window, self-insulation wall cast-in-place at the top of the window and the top of the wall, The upper lintel insulation body of the door frame; the specific method and structure are as follows:

[0092] (1) The method and structure of the A-type composite thermal insulation block self-insulation wall (1): use the A-type composite thermal insulation block (3) to build the A-type composite thermal insulation block self-insulation wall (1), and the A-type composite thermal insulation block The width ...

Embodiment approach 3

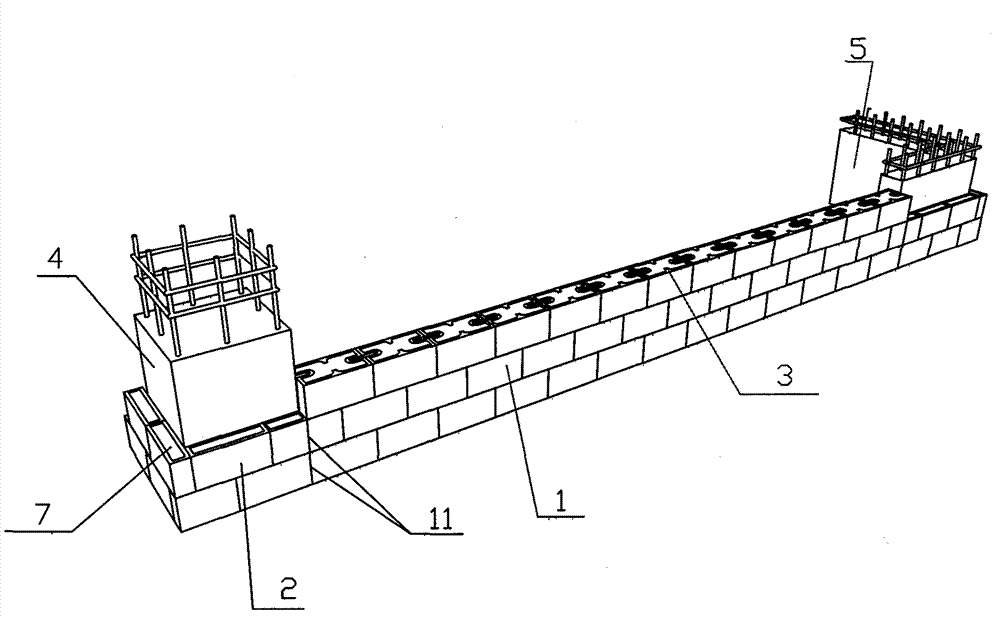

[0103] Such as image 3 , Figure 6 As shown, a self-insulation system of a semi-outsourcing cast-in-place wall is characterized in that the thermal insulation coating and the semi-outsourcing cast-in-place wall self-insulation system include an A-type composite thermal insulation block self-insulation wall ( 1), B-type composite thermal insulation block self-insulation wall (2), oblique brick self-insulation wall and beam insulation body, self-insulation wall on both sides of the window, self-insulation wall cast-in-place at the top of the window and the top of the wall, The upper lintel insulation body of the door frame; the specific method and structure are as follows:

[0104] (1) The method and structure of the A-type composite thermal insulation block self-insulation wall (1): use the A-type composite thermal insulation block (3) to build the A-type composite thermal insulation block self-insulation wall (1), and the A-type composite thermal insulation block The width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com