Steel structure outer wall self-thermal insulation system comprising SPB self-thermal insulation strip plates

A self-insulation and steel structure technology, applied in the direction of insulation, walls, building components, etc., can solve the problems of low compressive and tensile strength, easy aging, short service life, poor insulation effect, etc., to increase life, good insulation effect, shorten The effect of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Referring to the accompanying drawings, the present invention will be further described in detail with specific embodiments.

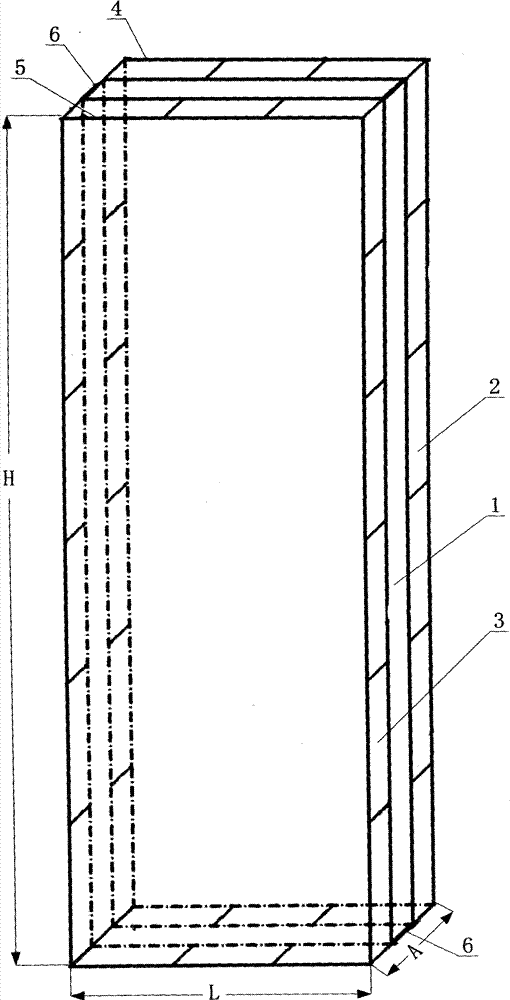

[0032] Such as figure 1 As shown, the lightweight steel mesh concrete self-insulating exterior wall strip (SPB for short, the pinyin abbreviation of "solid ordinary wallboard") has a three-layer structure, consisting of SPB self-insulating strip 1, the first SPB self-insulating strip with steel wire grid The insulation strip 2 and the second SPB self-insulation strip 3 with a steel wire frame are composed. The SPB self-insulation slat 1 is the middle layer, which is sandwiched between the first SPB self-insulation slat 2 with a steel wire mesh frame and the second SPB self-insulation slat 3 with a steel wire mesh frame on both sides. The first SPB self-insulation slat 2 with a steel wire grid is formed by filling the first steel wire grid 4 with thermal insulation materials, and the second SPB self-insulation slat 3 with a steel wire grid is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com