Composite high-order cycloidal planetary transmission device

A planetary transmission, high-level technology, applied in transmissions, gear transmissions, transmission parts, etc., can solve the problems of tedious selection and calculation of gear geometric parameters, less practical experience, and difficult to guarantee accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

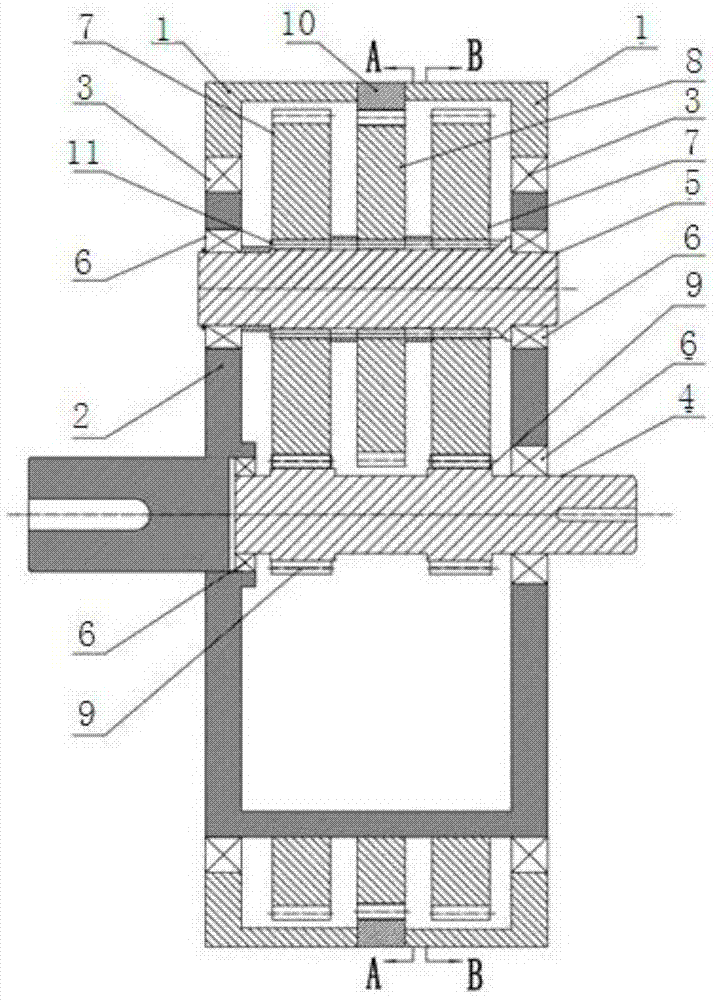

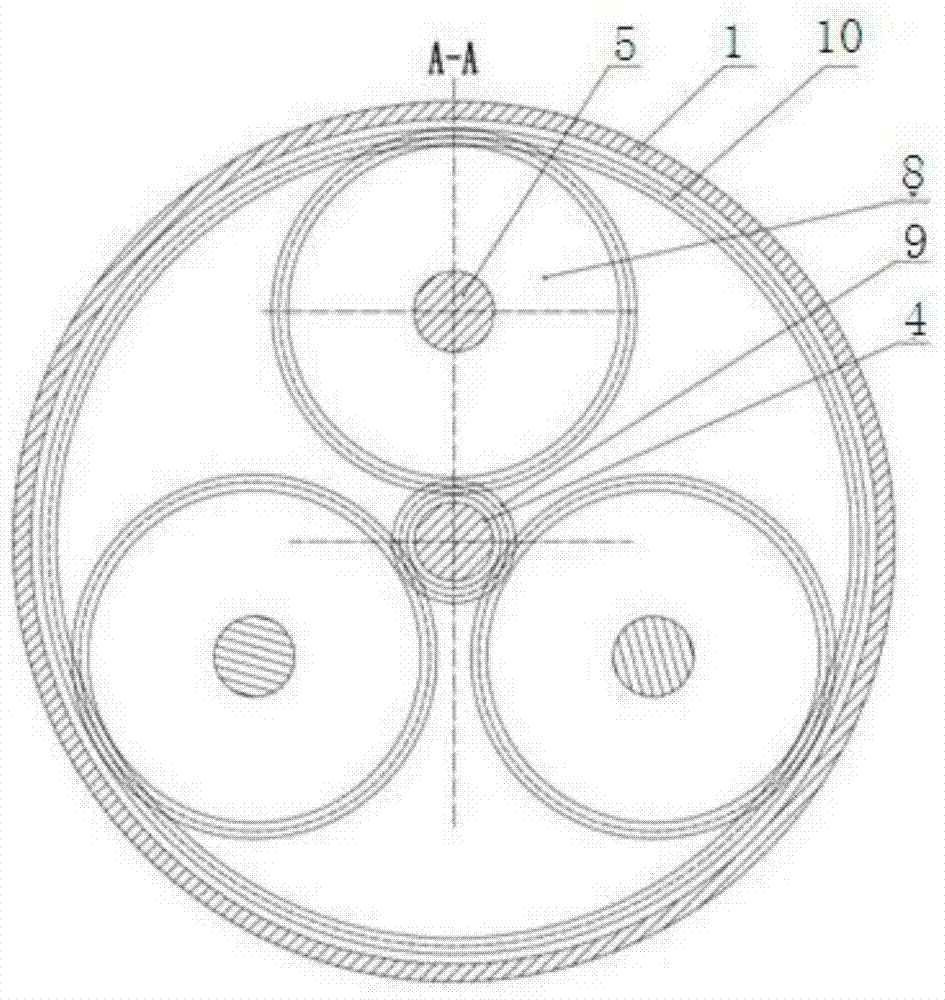

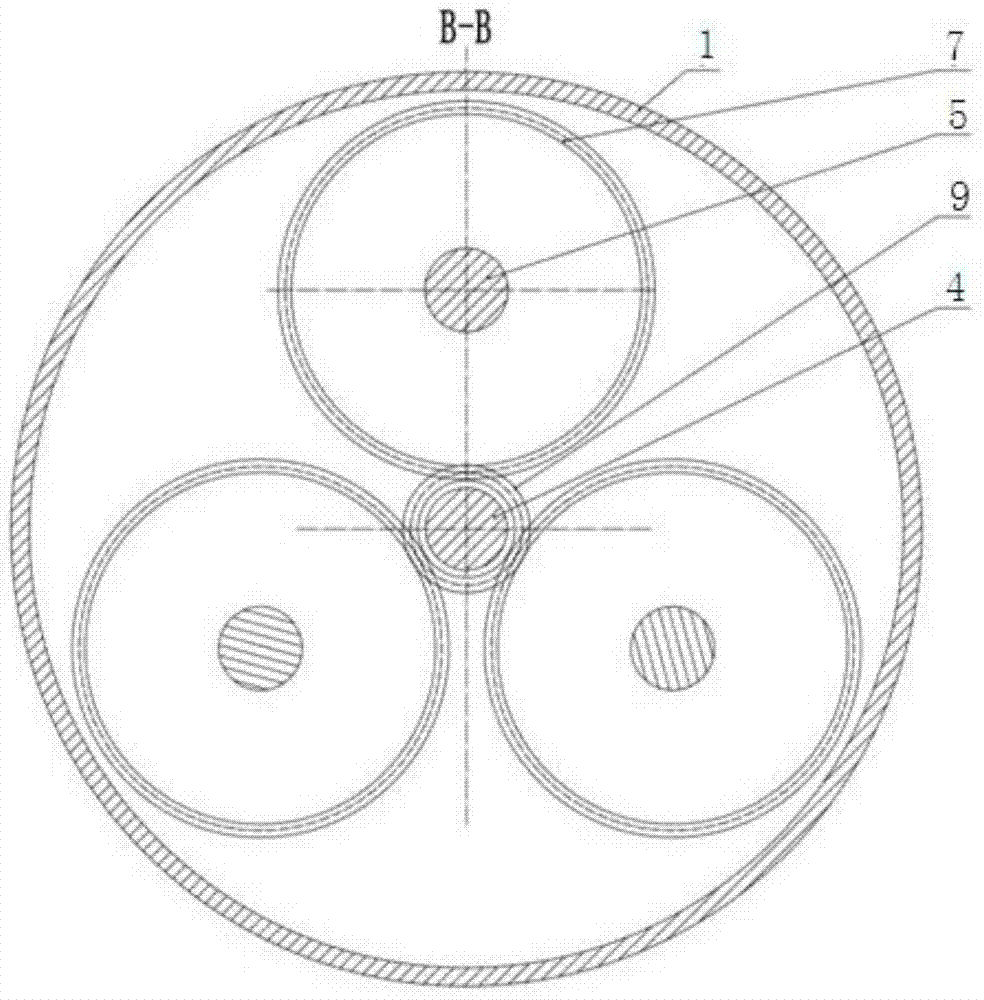

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] As shown in the figure, the composite high-order cycloidal planetary transmission device in this embodiment includes a box body 1 and a planet carrier 2, and the planet carrier 2 is arranged on the box body 1 through a supporting bearing 3; the planet carrier 2 An input shaft 4 and several planetary shafts 5 are arranged on the top, and each planetary shaft 5 is evenly distributed around the input shaft 4, and the planetary shafts 5 and the input shafts 4 are supported and fixed on the planet carrier 2 through bearings 6; each planetary shaft 5 The involute planetary gear 7 and the high-order cycloid planetary gear 8 are fixed on it, the sun gear 9 is correspondingly fixed on the input shaft 4, the ring gear 10 is correspondingly fixed on the box body 1, and the involute planetary The gear 7 meshes with the sun gear 9 and the high-or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com