Pipeline joint coating structure

A pipeline and joint filling technology, which is applied in the field of gas transmission and oil pipeline construction, can solve problems such as debonding and cracking, limited pressure of hot melt adhesives, environmental damage, etc., to achieve improved bonding strength, long-term stable performance, and no environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific embodiments. The following examples are preferred implementation forms of the present invention, but the implementation manners of the present invention are not limited by the following examples.

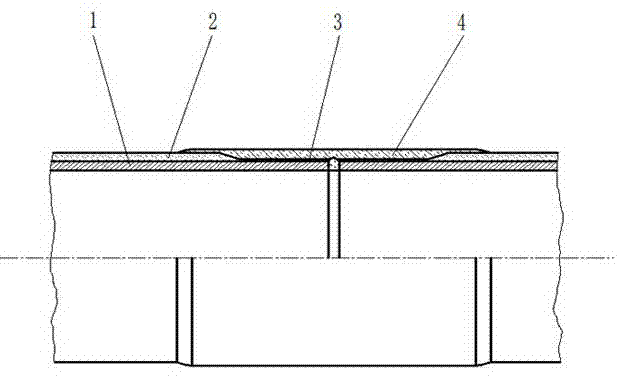

[0020] Such as figure 1 As shown, a Ф1219 3LPE pipe joint joint includes butt steel pipe 1 and prefabricated anticorrosion layer 2 at both ends. An epoxy primer layer 3 is provided, and the outer periphery of the epoxy primer layer 3 is covered with a layer of thermoplastic patch 4, the patch 4 is completely covered with the epoxy primer layer 3 and the two ends and the two ends are prefabricated with anti-corrosion layers 2 overlapping.

[0021] The mouth patch 4 is made of maleic anhydride grafted polyethylene copolymer, the grafting rate is 0.25wt%, and the mouth patch 4 has a thickness of 4.2mm.

[0022] The length of the straight part of the joint patch 4 along the axial direction of the pipeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com