Circuit board debugging and detecting system and application method thereof

A detection system and circuit board technology, applied in the direction of electronic circuit testing, etc., can solve problems such as low accuracy, error-prone, and many hidden dangers, and achieve the effects of eliminating the cause of failure, facilitating management, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

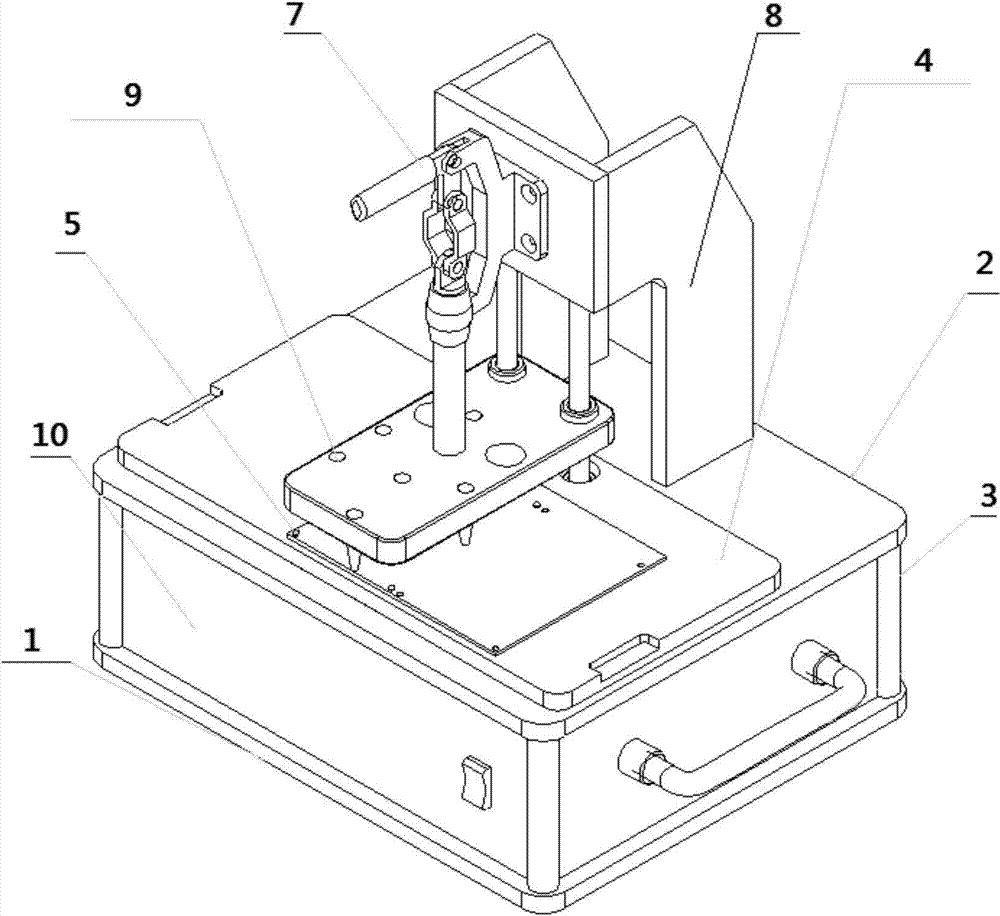

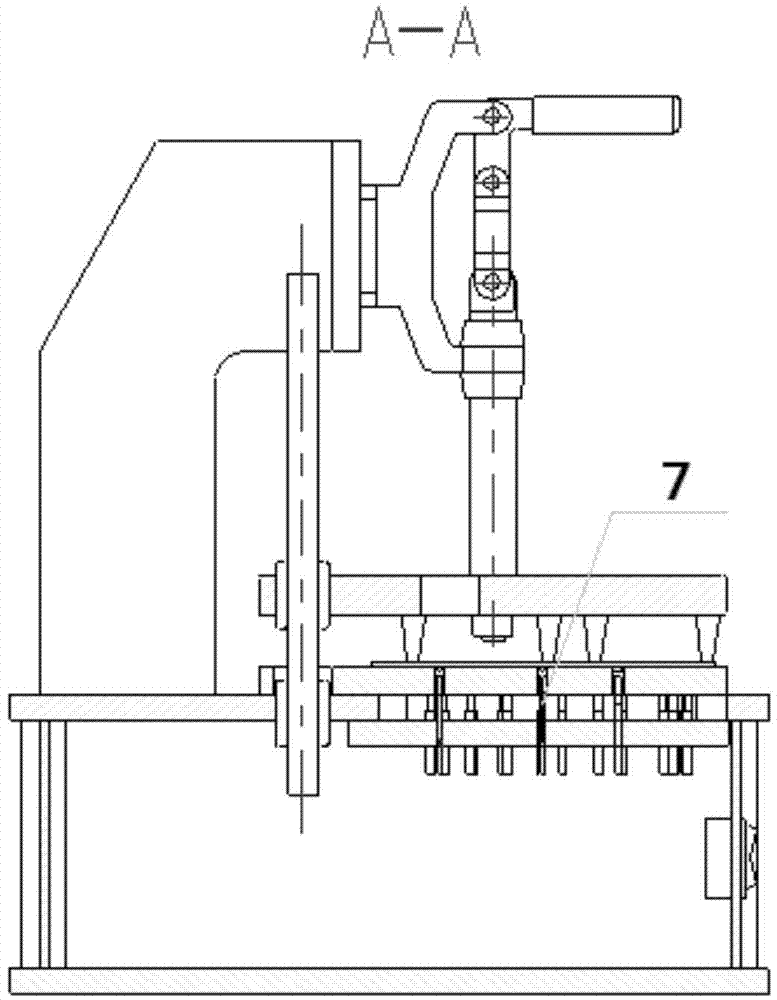

[0031] like Figure 1 to Figure 3 As shown, a circuit board debugging and testing system provided in this embodiment includes a probe fixture and a transmission system built in the probe fixture and a PC respectively, wherein: the probe fixture includes a square bottom plate arranged horizontally And the square panel located above the bottom plate, the bottom plate and the panel are corresponding and parallel to each other, the bottom plate and the panel are fixedly connected by aluminum support columns vertically arranged at the four corners, and the panel is also laid with a PCB supporting board. The PCB supporting plate is installed on the panel through springs, limit screws and bearing columns. There is also a detection slot in the middle of the PCB supporting plate for placing the circuit board to be tested, and a probe is provided on the upper surface of the detection slot;

[0032] It also includes a support frame vertically arranged on the panel, and a clamp is install...

Embodiment 2

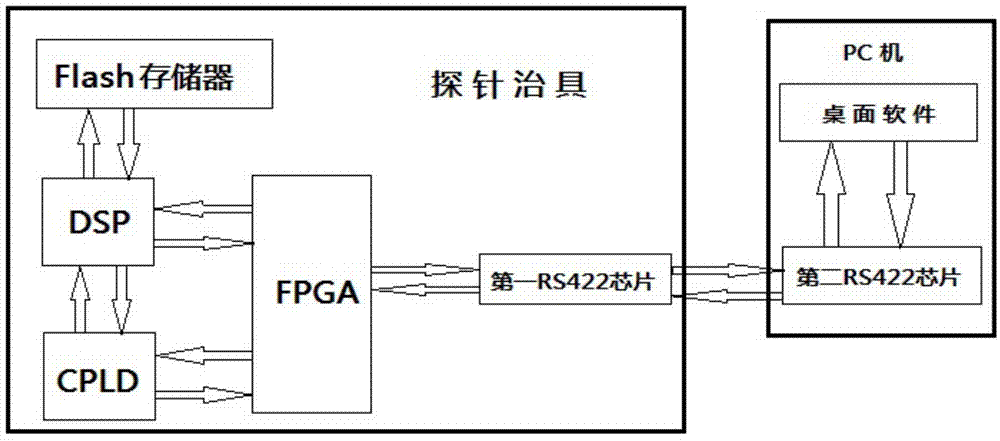

[0038] like Figure 4 As shown, the application method of a circuit board debugging and detection system provided in this embodiment includes the following specific steps:

[0039] Step (1) First use FPGA to determine the receiving timing and sending timing of running DSP for serial port debugging, and use DSP for serial port debugging;

[0040] Step (2) Place the circuit board to be tested, quickly clamp the circuit board with the clamp, and connect each test point through the probe. The desktop software analyzes, records and counts the data while testing the circuit board.

[0041] Furthermore, in the application method of the aforementioned circuit board debugging and detection system, the specific operation of step (1) is as follows:

[0042] Step a: correspondingly connect the sending pin of the first RS422 serial chip set with the receiving pin of the second RS422 serial chip set;

[0043] Step b: connect the JTAG port of CPLD, and download it;

[0044] Step c: After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com