An accordion bass machine

A bass machine and accordion technology, applied to accordions, wind instruments, instruments, etc., can solve the problems of poor workpiece position accuracy, high accuracy requirements, and low production efficiency, and achieve high accuracy, high assembly accuracy, and low maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

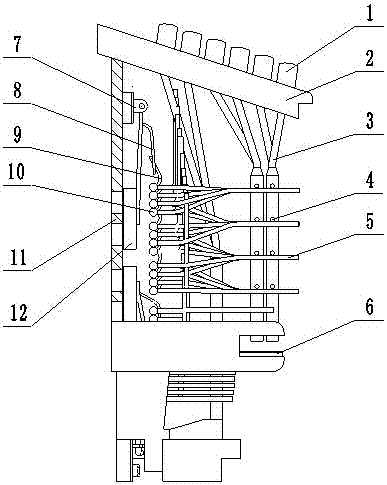

[0014] like figure 1 As shown, the accordion bass machine of the present invention comprises a key button 1, a button plate 2, a top piece 3, a rolling thread 10, a sound hole plate 11, a sound hole cover 12 and a starting frame 7, and a top piece is installed on the top piece Nail 4, thread rolling 10 are provided with upright pile 5 and ejector rod 9 in the circumferential direction, and connecting rod 8 is installed on the swing arm of starting frame 7. When thread rolling 10 rotates, ejector rod 9 can be driven to move connecting rod 8 to drive starting frame 7 Open the sound hole cover 12, the integral structure of the top sheet 3 integrally formed, the top sheet nail 4 is a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com