Insulated gate bipolar transistor (IGBT) deep-trench photolithographic process

A photolithography process and deep trench technology, applied in the field of microelectronics, can solve the problems of insufficient, poor etching effect of IGBT deep trenches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

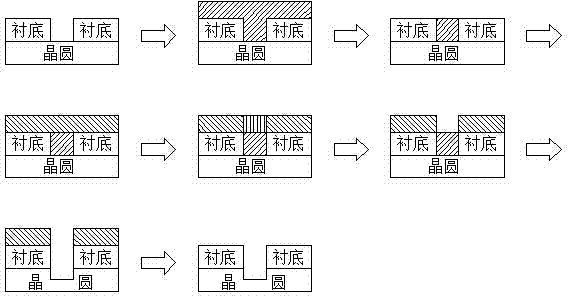

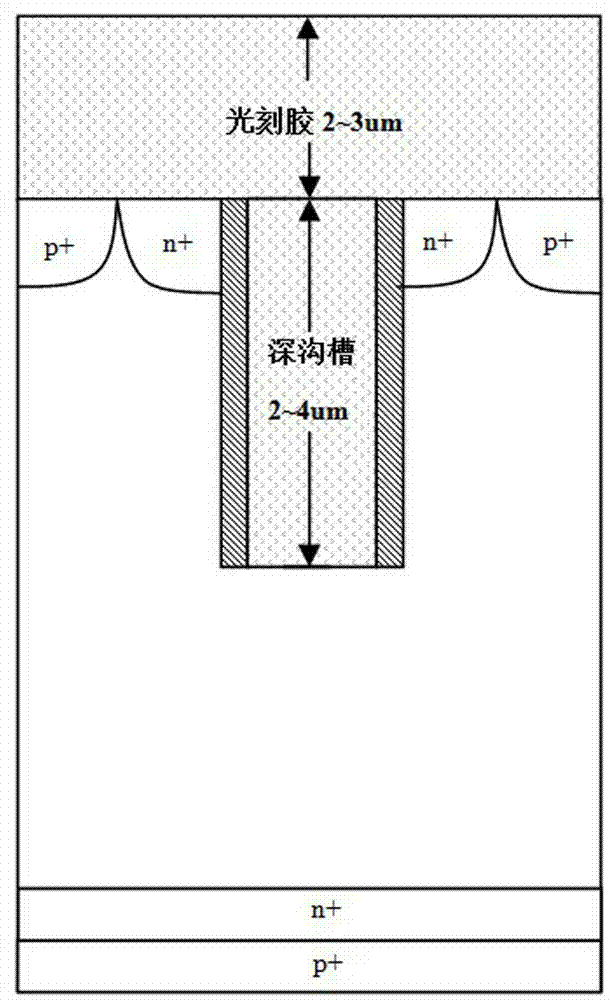

[0030] Since in the process of manufacturing IGBT devices, it is necessary to perform photolithography on the deep grooves on the device substrate, so that the wafer at the bottom of the deep grooves can be etched with a certain pattern, this embodiment provides a new deep groove photolithography method. Engraving process, pre-filling organic materials in deep trenches, other processes are all existing technologies, such as figure 1 As shown, the specific steps are as follows:

[0031] (1) Use a rotary coating machine to coat a layer of organic material on the surface of the substrate and in the deep groove at a speed of 850 rpm; the organic material is GF52 from Nissan (Nissan) in Japan. The composition is also a polymer resin, but there is no cross-linkable functional group contained in the photoresist, and no cross-linking reaction occurs after exposure, so it will not be dissolved by the developer. ;

[0032] (2) remove the organic material on the surface of the silicon...

Embodiment 2

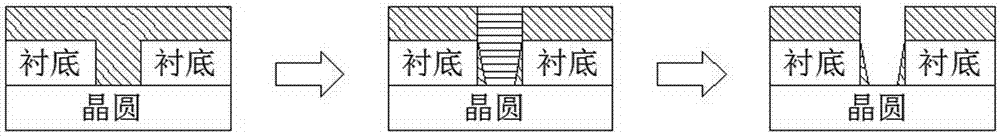

[0040] This embodiment continues to provide a deep trench photolithography process, using a negative resist to fill the deep trench, and the specific steps are as follows:

[0041] (1) Coat negative resist on the surface of the silicon dioxide substrate and in the deep groove. This negative resist is SG6200 negative resist produced by Fuji Film. This negative resist is insoluble in developer after exposure, but can be engraved eclipse;

[0042] (2) Expose the SG6200 negative glue in and above the deep groove, and remove the unexposed negative glue on the surface of the silicon dioxide substrate with a developer, so that the negative glue is filled in the deep groove;

[0043] (3) Coating a layer of American Rohm and Haas SEPR955 positive resist on the surface of the silica substrate and the surface of the organic material;

[0044] (4) Cover the SEPR955 positive resist above the silicon dioxide substrate with a mask plate to expose the SEPR955 positive resist above the deep g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com