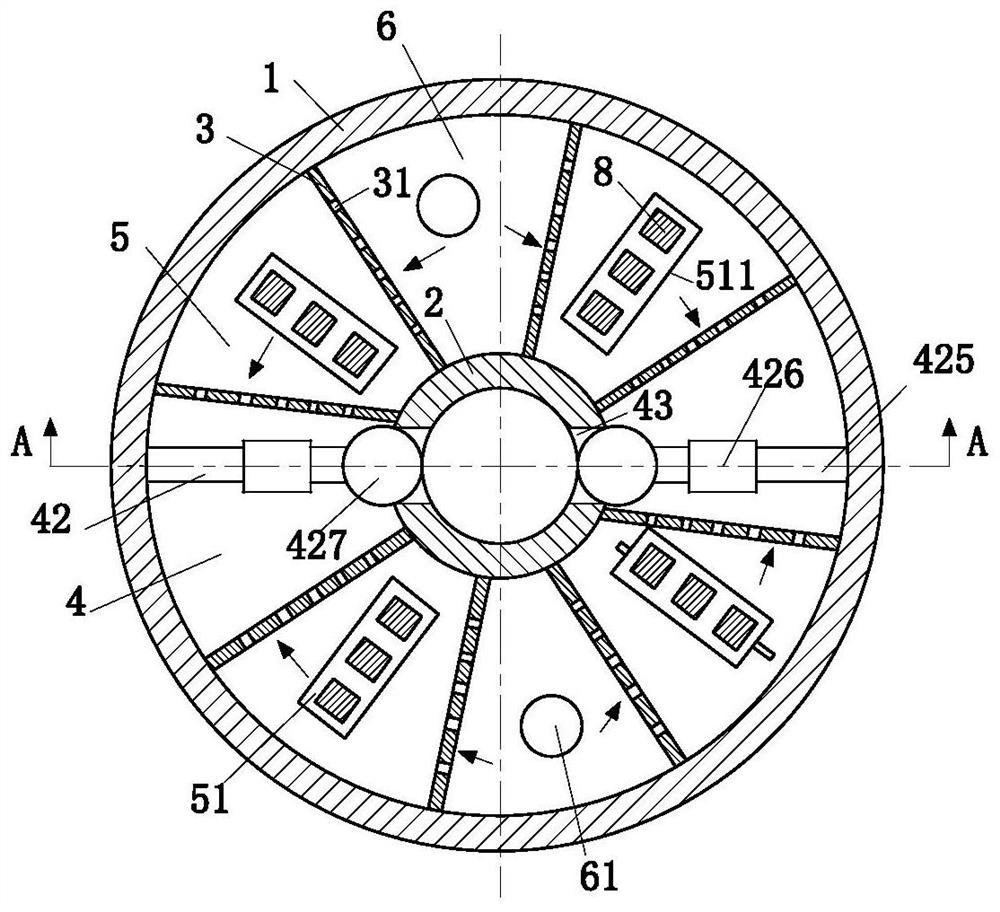

A wafer wet etching device

A wet etching and wafer technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as wafer clamping, technical solution limitations, and uniform etching, etc., to increase the contact area , Improve the effect of etching and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

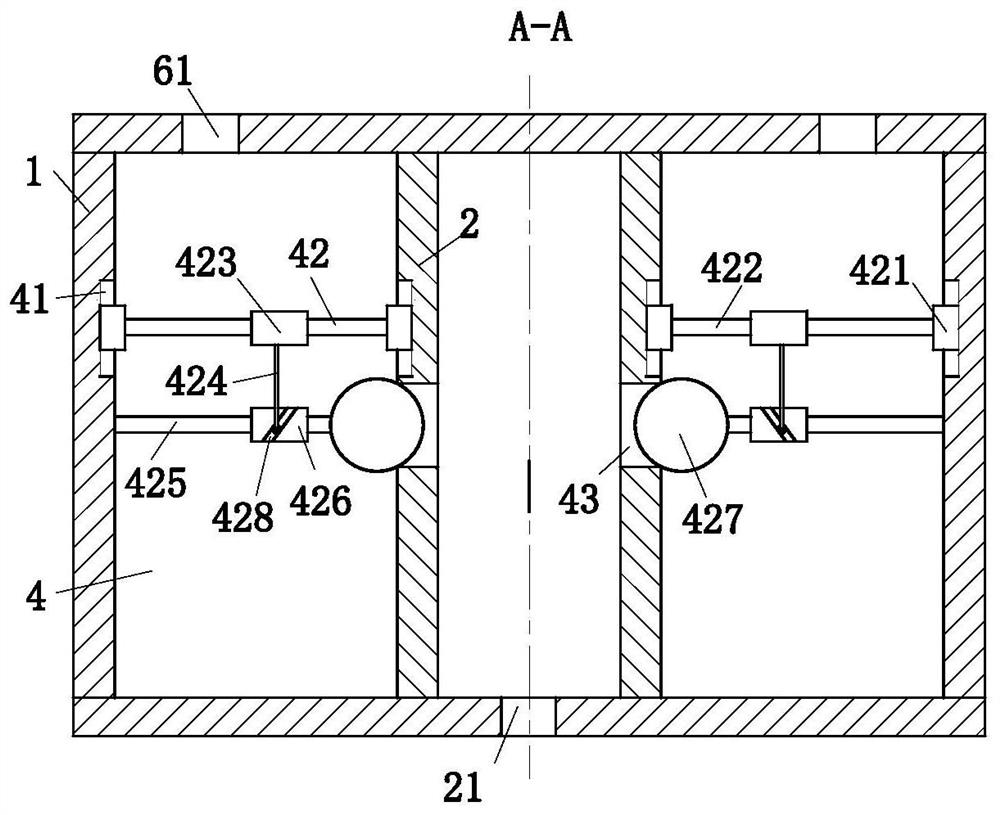

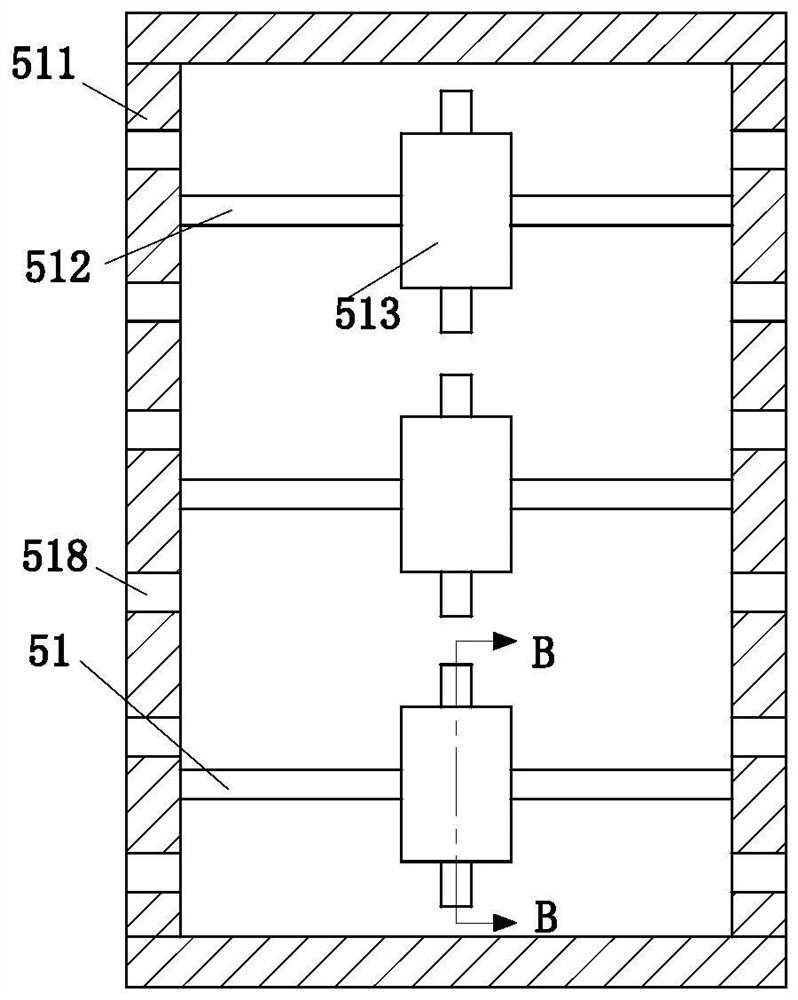

[0024]As an embodiment of the present invention, the liquid blocking module 42 includes a No. 1 slider 421, a No. 1 guide rod 422, a floating block 423, a No. 2 guide rod 424, a No. 1 sliding telescopic rod 425, and a No. 3 slider 426. and a spherical stopper 427; the floating block 423 is fixedly connected with the No. 1 slider 421 through the No. 1 guide rod 422; the No. 1 slider 421 slides on the No. 1 chute 41; the slider 423 below is provided with three No. slider 426; No. 2 chute 428 is provided in the No. 3 slider 426; One end of No. 2 guide rod 424 is connected with floating block 423; The other end of No. 2 guide rod 424 is provided with No. 2 slider 429 , which is used to drive the movement of No. 3 slider 426; said No. 3 slider 426 is fixedly connected with spherical stopper 427 through one end of No. 1 sliding telescopic rod 425, and the other end of No. 1 sliding telescopic rod 425 is connected with No. The wall is fixedly connected; the spherical stopper 427 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com