Etching method of medium carbon steel substrate, antifriction and wear-resisting composite lubricating film and preparation method of antifriction and wear-resisting composite lubricating film

A technology of lubricating film and carbon steel, which is applied to the device for coating liquid on the surface, coating, pretreatment surface, etc., can solve the problems of complicated processing process and high etching cost, and achieve simple preparation process, low price and low cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Wash with acetone, petroleum ether, absolute ethanol and deionized water for 45 # Steel surface to fully remove grease and other impurities on the surface of the sample. The frequency of ultrasonic cleaning is 25kHz, using acetone ultrasonic cleaning for 2 minutes, petroleum ether ultrasonic cleaning for 5 minutes, absolute ethanol ultrasonic cleaning for 10 minutes, and deionized water ultrasonic cleaning. Wash for 2 minutes; then carry out a nitrogen blowing drying process at a rate of 25L / min for 6 minutes, and dry it for later use.

[0081] 45 after drying # Steel with FeCl 3 The concentration is 75g / L and the mixed solution of HCl concentration is 25g / L soaks, carries out 1 hour insulation at 50 ℃ through constant temperature water bath, takes out 45 # Ultrasonic oscillation with absolute ethanol for 5 minutes and deionized water for 5 minutes after steeling to remove FeCl 3 The solution and the residue of hydrochloric acid were then dried by nitrogen blowing at...

Embodiment 2

[0086] In this example, FeCl 3 Concentration is 75g / L and HCl concentration is the mixed solution of 50g / L to pretreated 45 # Steel was etched, and the remaining conditions were exactly the same as in Example 1.

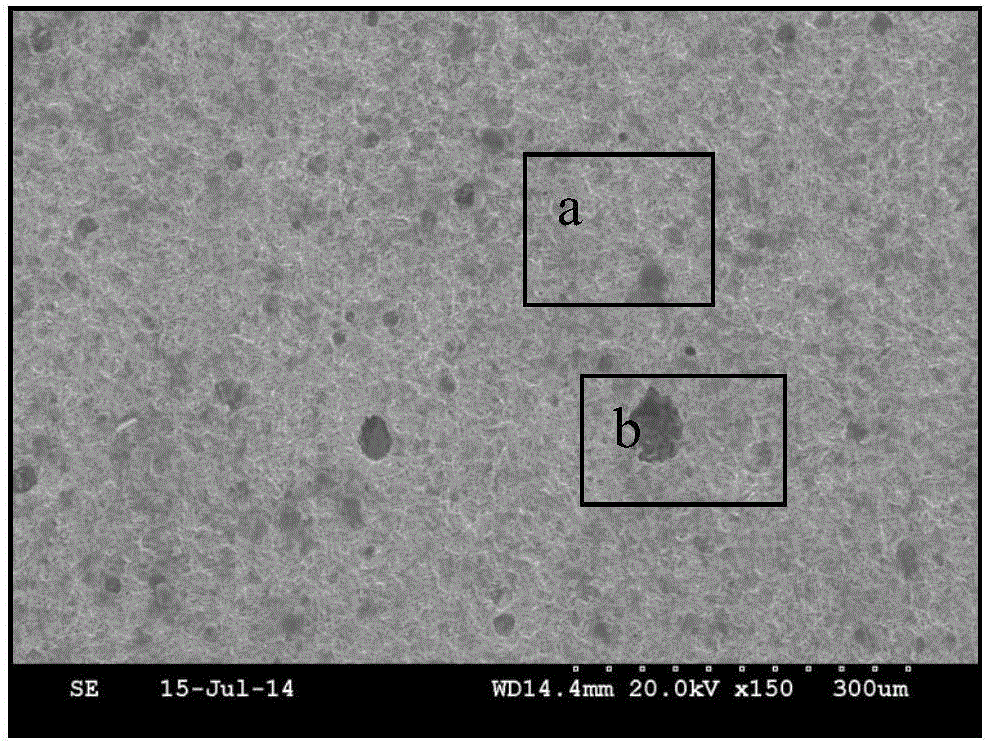

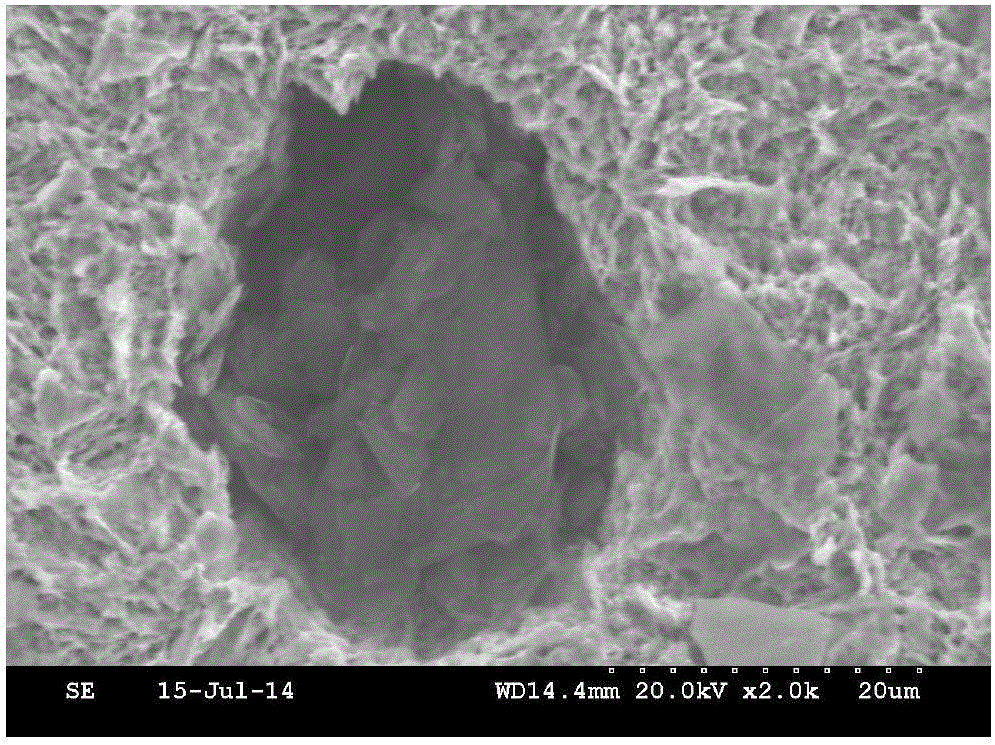

[0087] Meanwhile, for the 45 completed etching # The steel was observed by SEM, and the results of SEM observation were as follows: Figures 24 to 26 shown, where Figure 25 and Figure 26 respectively Figure 24 Partial enlarged images corresponding to n and o in the figure.

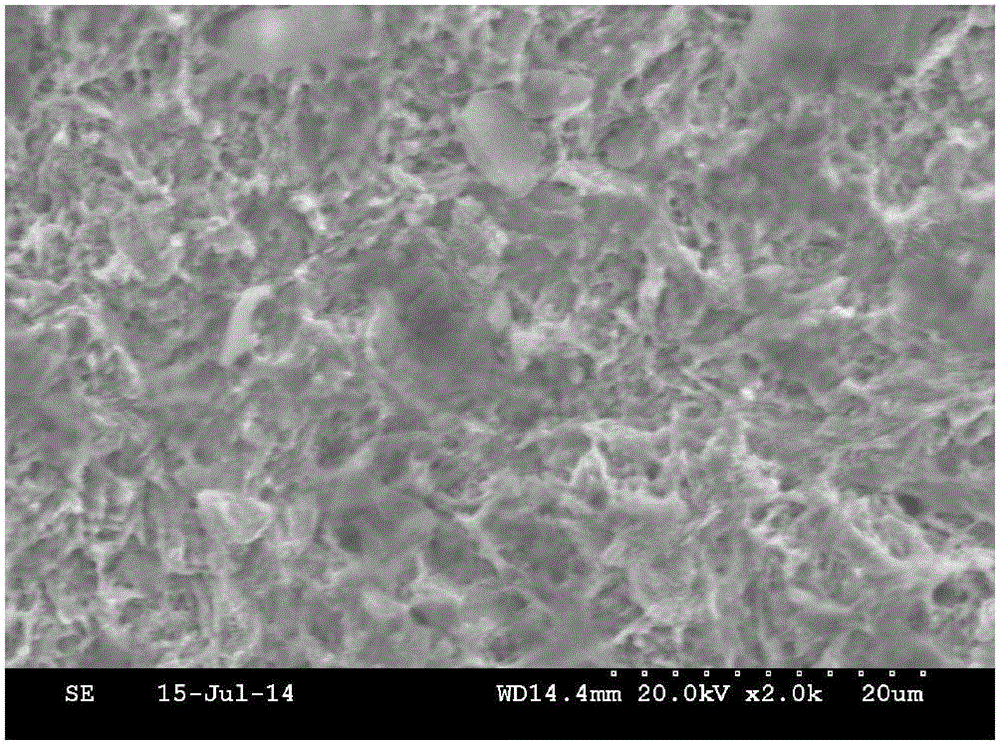

[0088] SEM observation was carried out on the obtained composite lubricating film, and the SEM observation results were as follows: Figure 4~6 shown, where Figure 5 and Figure 6 respectively Figure 4 The corresponding local enlarged pictures in c and d, and the friction test was carried out on the obtained composite lubricating film at a friction speed of 24mm / s. The appearance of wear scars is as described in 15 and 16. Figure 16 yes Figure 15 The i in corresponds to the loca...

Embodiment 3

[0090] In this example, FeCl 3 Concentration is 75g / L and HCl concentration is the mixed solution of 75g / L to pretreated 45 # Steel was etched, and the remaining conditions were exactly the same as in Example 1.

[0091] Meanwhile, for the 45 completed etching # The steel was observed by SEM, and the results of SEM observation were as follows: Figures 27-29 shown, where Figure 28 and Figure 29 respectively Figure 27 Partial enlarged images corresponding to p and q in the figure.

[0092] SEM observation was carried out on the obtained composite lubricating film, and the SEM observation results were as follows: Figure 7-9 shown, where Figure 8 and Figure 9 respectively Figure 7 The corresponding partial enlarged pictures in e and f, and the friction test was carried out on the obtained composite lubricating film at a friction speed of 24mm / s. The appearance of wear scars is as described in 17 and 18. Figure 18 yes Figure 17 The g in corresponds to the local...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com