A method for rapidly completing the operation of chip buckling edge sheet, a mold, a mold manufacturing method, and a mold storage device

A manufacturing method and edge-cutting technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as low production efficiency and cumbersome operation, and achieve the effects of improved efficiency, high economic benefits, and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

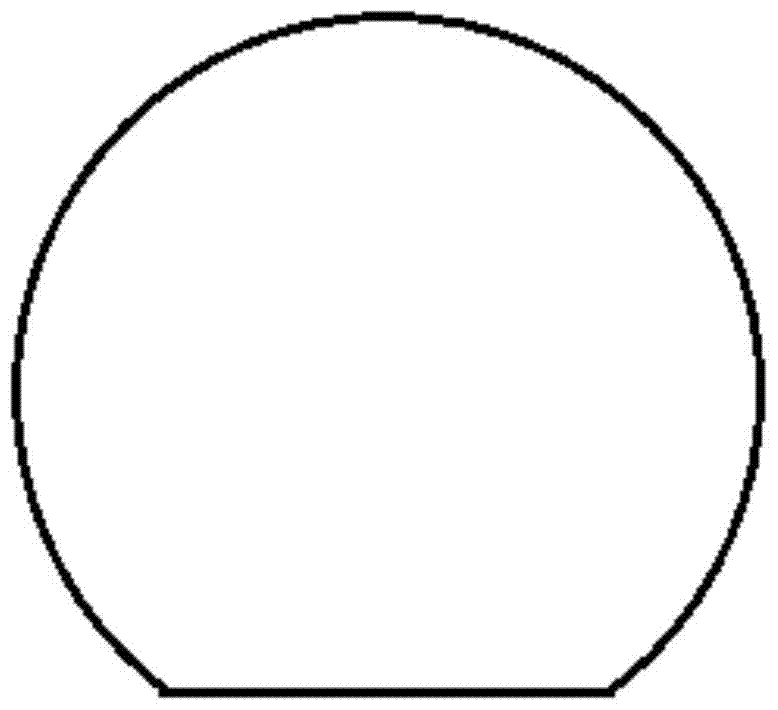

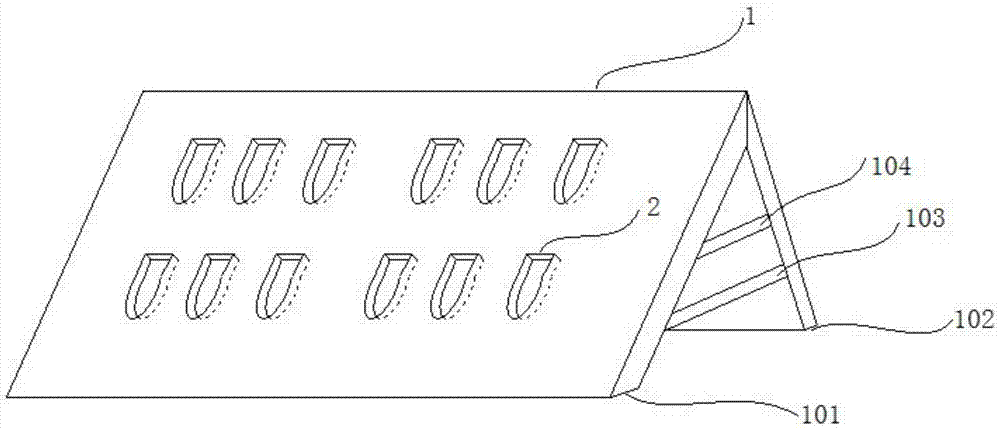

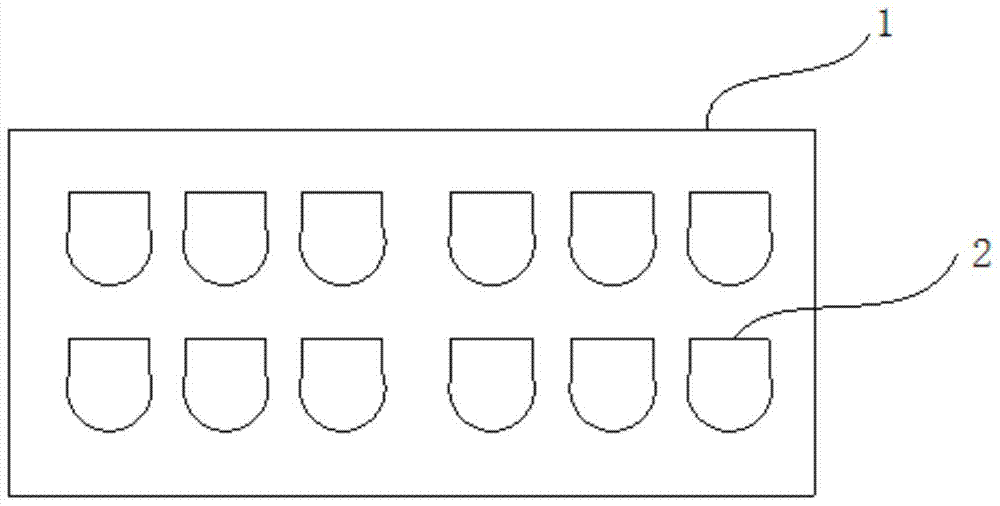

[0045] Such as figure 1 As shown in the figure, a mold for quickly completing the operation of buckling the edge of the chip, the mold is in the shape of a disc, with a diameter of D = 78-[x] / 2mm, where x is the percentage value of the edge in the photoelectric parameter diagram of the chip, [x] Indicates that x is rounded to a single digit according to the rounding principle (the side part of the chip is a chip with poor photoelectric parameters, in order to ensure that the center part of the chip is not mixed with chips with poor photoelectric parameters, the Appropriately relax the ratio to improve the quality of the center chip. Therefore, in the actual production process of the enterprise, when [x] is 6-10, press [x] to be 13 to make a mold of the corresponding size, and when [x] is 11-15, press [x] is 18 to make the mold of corresponding size, and [x] is 16-20 to be 23 to make the mold of corresponding size by [x], the mold of preparation 3 sizes gets final product.), in...

Embodiment 2

[0063] A mold for quickly completing the operation of buckling the edge of the chip. The mold is in the shape of a disc, with a diameter of D=78-[x] / 2mm, where x is the percentage value of the edge in the photoelectric parameter diagram of the chip, and [x] represents the basis of rounding In principle, x is rounded to a single digit. In this example, [x] is 13. In the actual production process, [x] is 18 to make a mold of the corresponding size. The mold is made of blue film and flat release paper , There is a slit on the edge of the mold, the distance between the slit and the center of the mold is 2 / 15 of the diameter of the mold, and the thickness of the mold is 2mm.

[0064] The preparation steps of the blue film in this example are as follows: heating and melting the polybutylene terephthalate (polyester) raw material, and then using a PET transparent film (thickness of 100 μm) as the base layer, and using a flat film scraping machine on its surface (Denoted as A side) sc...

Embodiment 3

[0081]A mold for quickly completing the operation of buckling the edge of the chip. The mold is in the shape of a disc, with a diameter of D=78-[x] / 2mm, where x is the percentage value of the edge in the photoelectric parameter diagram of the chip, and [x] represents the basis of rounding In principle, x is rounded to a single digit. In this example, [x] is 20. In the actual production process, [x] is 23 to make a mold of the corresponding size. The mold is made of blue film and flat release paper , There is a slit on the edge of the mold, the distance between the slit and the center of the mold is 1 / 8 of the diameter of the mold, and the thickness of the mold is 1.5mm.

[0082] The preparation steps of the blue film in this example are as follows: heating and melting the polybutylene terephthalate (polyester) raw material, and then using a PET transparent film (thickness of 300 μm) as the base layer, and using a flat film scraping machine on its surface (Denoted as A side) sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com