High-performance current-type multi-switching LED controller

A LED controller, current-type technology, applied in the field of high-performance current-type multi-cut LED controller, can solve the problems of complete machine burnout, high constant current accuracy, low PF value, etc., to reduce system cost and system size , the effect of integration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

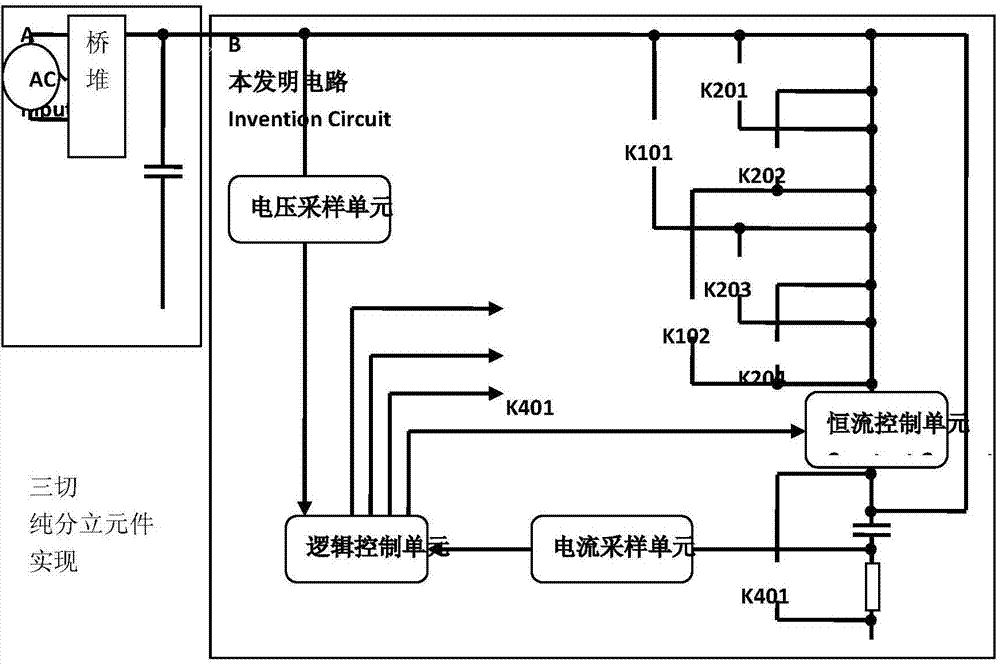

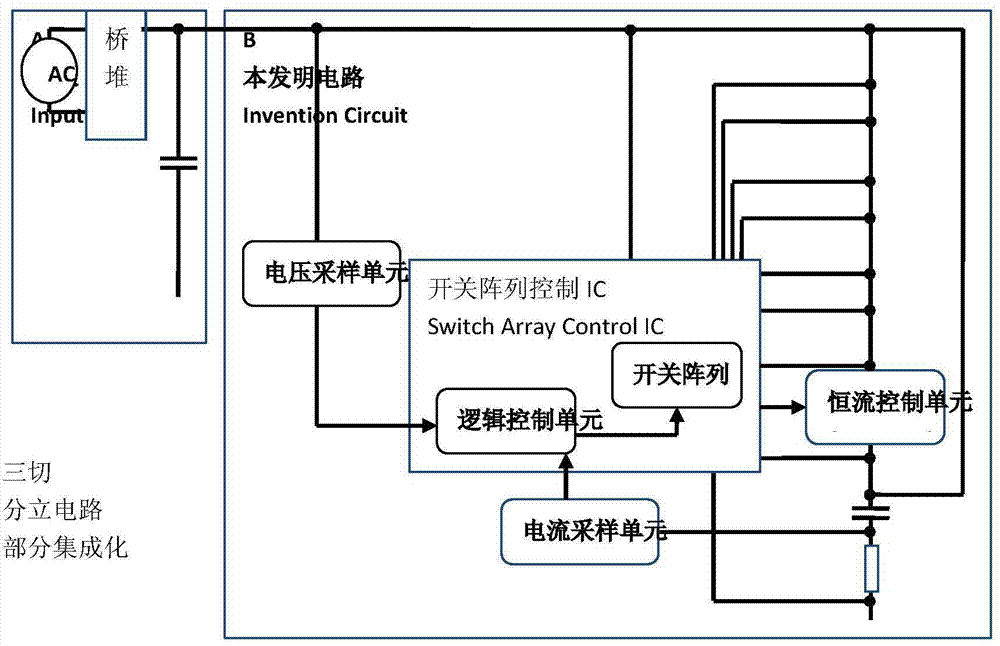

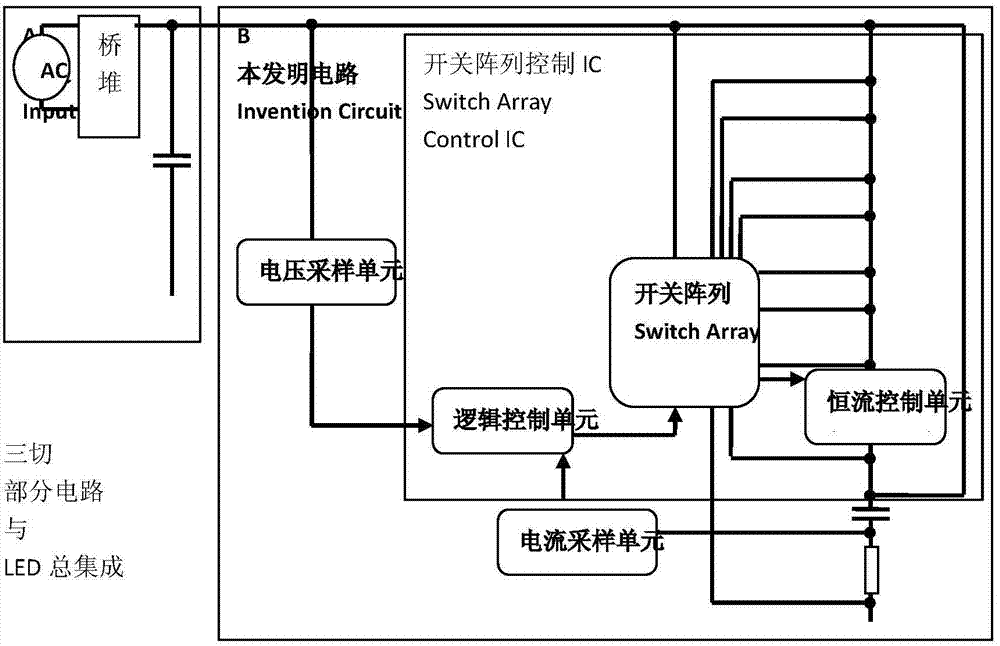

Embodiment 1

[0024] see figure 1 , including an input rectification unit, a voltage sampling unit, a logic control unit, a current sampling unit, a constant current control unit, a switch array, a capacitor, a resistor, and an LED light string composed of LED units; the LED light string head and the input rectification unit The output terminal is electrically connected, the tail is electrically connected to the constant current control unit, the other end of the constant current control unit is connected in series with the capacitor and the resistor in sequence, and the other end of the resistor is grounded; the LED unit between the two adjacent LED units and the tail A diode is also connected in series; the anode of the diode is connected to the negative pole of the adjacent LED unit, and the cathode of the diode is connected to the positive pole of the adjacent LED unit; the cathode of the diode at the tail and the positive pole of the LED unit at the head There is also a diode connected...

Embodiment 2

[0043] see Image 6 , the difference between this embodiment 2 and embodiment 1 is: in this embodiment 2, or by controlling 8 LED units through the switch array to realize the conversion of four-cut series to parallel; it also includes switches K103, K104, K205, K206, K207, K208 ,; K301 and K302. Other parts of Embodiment 2 are the same as Embodiment 1 and will not be described in detail.

[0044] Based on the above differences, see Figure 7 , Figure 8 , Figure 9 and Figure 10 , Analysis of the four-cutting principle in Example 2: Assume that the peak value of the input voltage Vin is Vp, and the LED voltage V LED It is 4 / 5*Vp, the steady-state initial voltage of the capacitor is Va, and the output current of a single LED string is I. The whole control is divided into two phases, the first phase is the phase of Vin falling from the peak value to 0, and the second phase is the phase of Vin rising from 0 to the peak value.

[0045] The first stage:

[0046] A, Vin d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com