Extraction method for odourless DHA oil

An extraction method and oil technology, which is applied in the research field of microbial oil extraction technology, can solve the problems of heavy oil smell, large loss rate, and high energy consumption, and achieve the goal of improving extraction efficiency, short time consumption, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

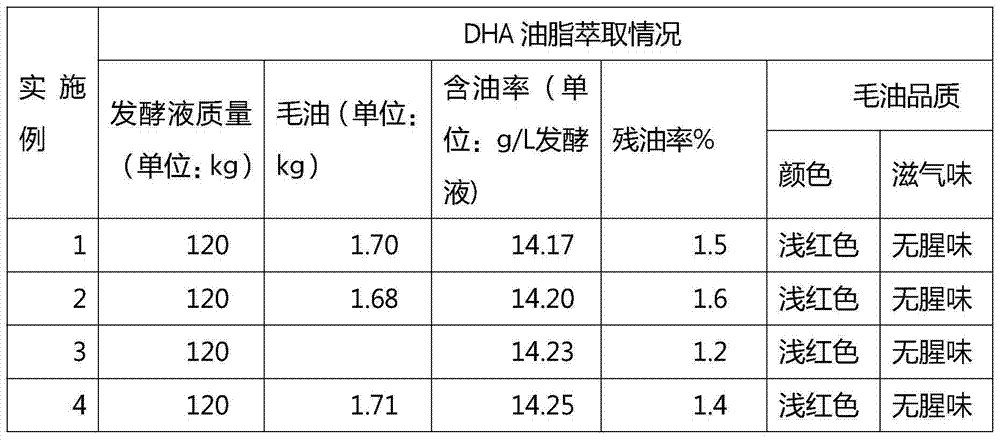

Examples

Embodiment 1

[0027] The extraction method of DHA oil without fishy smell comprises the following steps:

[0028] (1) Fermentation: Fermenting Schizochytrium containing DHA to obtain a fermented liquid;

[0029] (2), dehydration of the fermented liquid: leave the fermented liquid prepared in step (1) for 2 hours to settle naturally, remove 43% of the water in the fermented liquid, and take the sedimentation concentrate;

[0030] (3), water washing: use ceramic membrane to circulate and filter the concentrate, the ceramic membrane includes a first-stage filter membrane and a second-stage filter membrane, the diameter of the first-stage filter membrane is 1um; the diameter of the second-stage filter membrane is 0.5 um; after the first-level membrane filtration removes impurities in the fermentation broth, enter the second-level membrane filtration, and then wash the concentrated solution with water. The water temperature used for washing is 30°C, the washing time is 30min, and the water consu...

Embodiment 2

[0035] The extraction method of DHA oil without fishy smell comprises the following steps:

[0036] (1) Fermentation: Fermenting Schizochytrium containing DHA to obtain a fermented liquid;

[0037] (2), dehydration of the fermented liquid: leave the fermented liquid prepared in step (1) for 1.5 hours to settle naturally, remove 40% of the water in the fermented liquid, and take the sedimentation concentrate;

[0038] (3), water washing: use the ceramic membrane to circulate and filter the concentrate, the ceramic membrane includes a first-stage filter membrane and a second-stage filter membrane, the diameter of the first-stage filter membrane is 0.8um; the diameter of the second-stage filter membrane is 0.2um; after the first-stage membrane filtration removes impurities in the fermentation broth, enter the second-stage membrane filtration, and then wash the concentrated solution with water. The water temperature used for washing is 25°C, and the washing time is 30min. 2 times...

Embodiment 3

[0043]The extraction method of DHA oil without fishy smell comprises the following steps:

[0044] (1) Fermentation: Fermenting Schizochytrium containing DHA to obtain a fermented liquid;

[0045] (2), dehydration of the fermented liquid: leave the fermented liquid prepared in step (1) for 1 hour to settle naturally, remove 35% of the water in the fermented liquid, and take the sedimentation concentrate;

[0046] (3), water washing: use the ceramic membrane to circulate and filter the concentrate, the ceramic membrane includes a first-stage filter membrane and a second-stage filter membrane, the diameter of the first-stage filter membrane is 0.5um; the diameter of the second-stage filter membrane is 0.1um; after the first-stage membrane filtration removes impurities in the fermentation broth, enter the second-stage membrane filtration, and then wash the concentrated solution with water. The water temperature used for washing is 28°C, and the washing time is 30min. 2 times.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com