Displacement and oscillating angle measuring light path structure for two-dimensional holographic scanning exposure workbench

A technology for holographic scanning and measuring optical path, which is applied in the field of holographic scanning exposure two-dimensional table displacement and swing angle measurement optical path structure, which can solve the influence of interference field bearing platform measurement accuracy and the difficulty in processing and assembling Y-axis long reflectors and other problems to achieve the effect of reducing the difficulty of processing and assembly and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

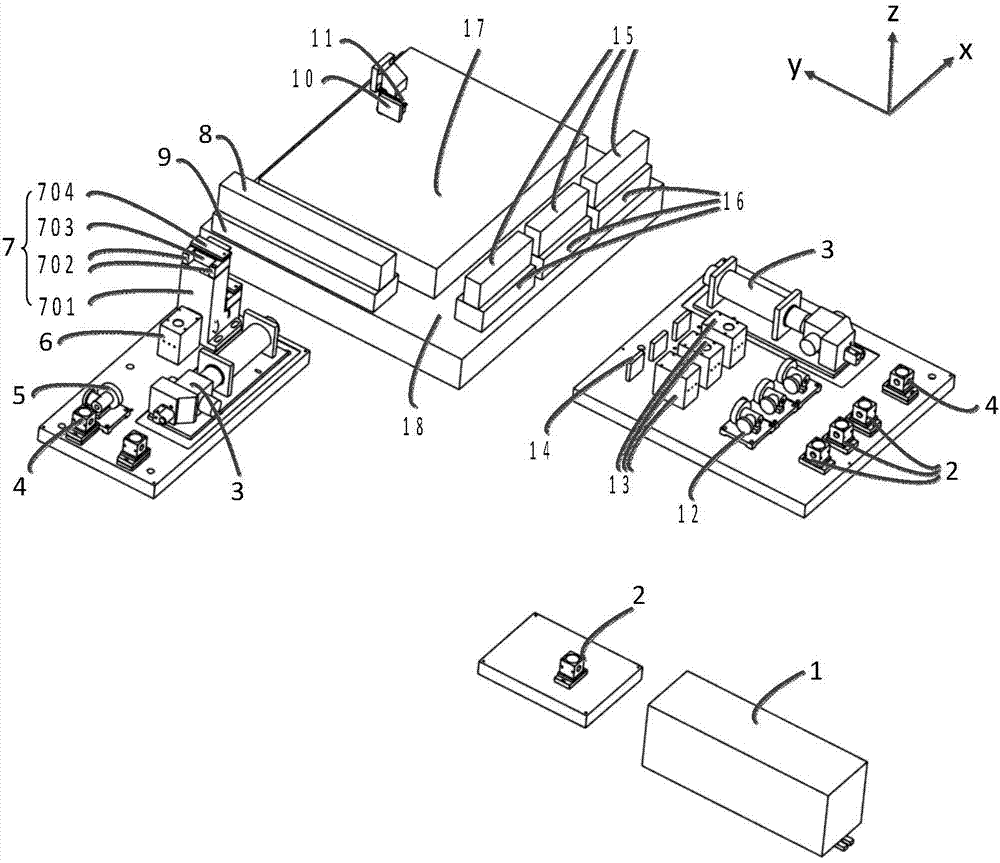

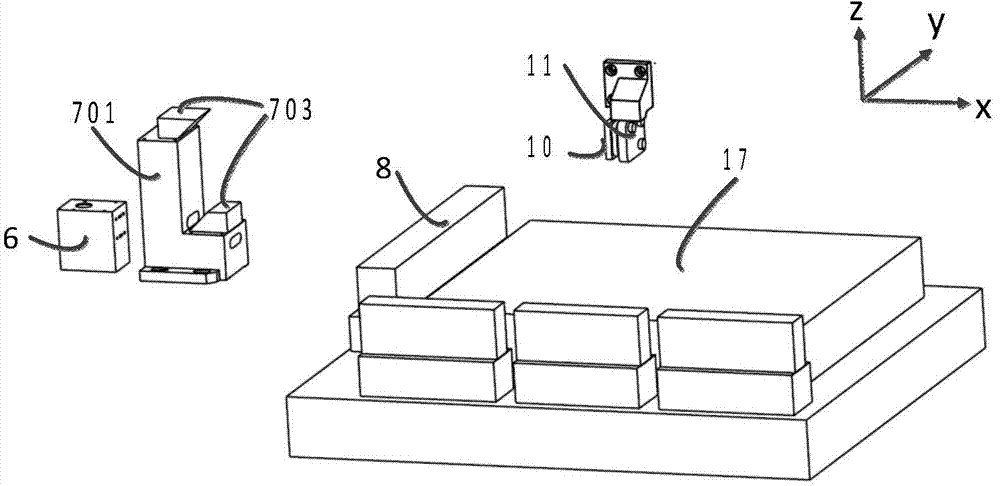

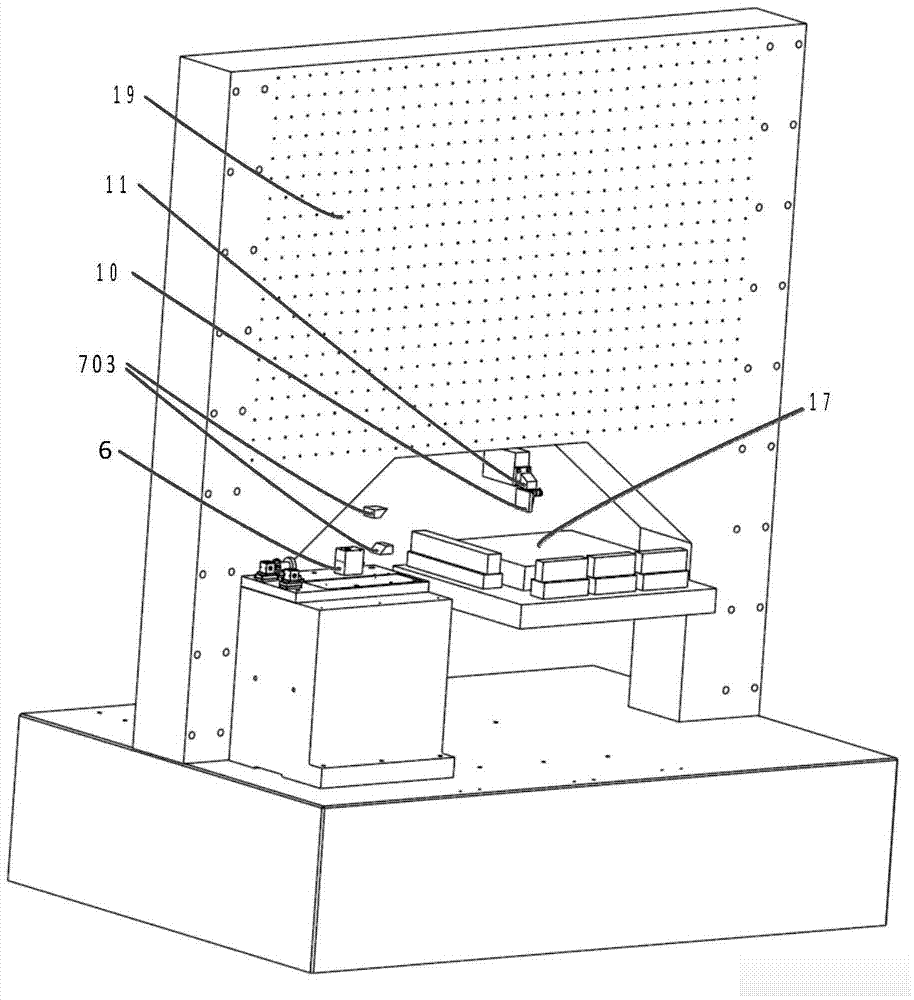

[0034] The method for measuring the displacement of the two-dimensional workbench 18 on the X-axis relative to the interference field is as follows: the laser light emitted by the dual-frequency laser 1 passes through the beam-splitting prism 2, and then enters the X-axis after being reflected by the steering prism 4 The beam direction adjuster 5 then enters the X-axis interferometer 6; after the beam passes through the X-axis interferometer 6, it is divided into two clusters of light up and down; the cluster of light on the top passes through the two periscope structures 7 to carry out the optical path After refraction, it is incident on the surface of the X-axis reference mirror 10, and then returns to the inside of the biaxial interferometer along the original optical path; a cluster of light located at the bottom of the X-axis interferometer 6 is reflected by the X-axis measurement After being reflected by the mirror 8, it returns to the interior of the X-axis interferomete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com