On-line hardness forecasting method of continuous annealing product by means of integrated learning

An integrated learning and annealing technology, used in prediction, special data processing applications, instruments, etc., can solve the problems of substandard hardness, difficulty in predicting accuracy and robustness of data modeling methods, waste products, etc., to improve accuracy and robustness. performance, improve the level of production operations, and increase the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

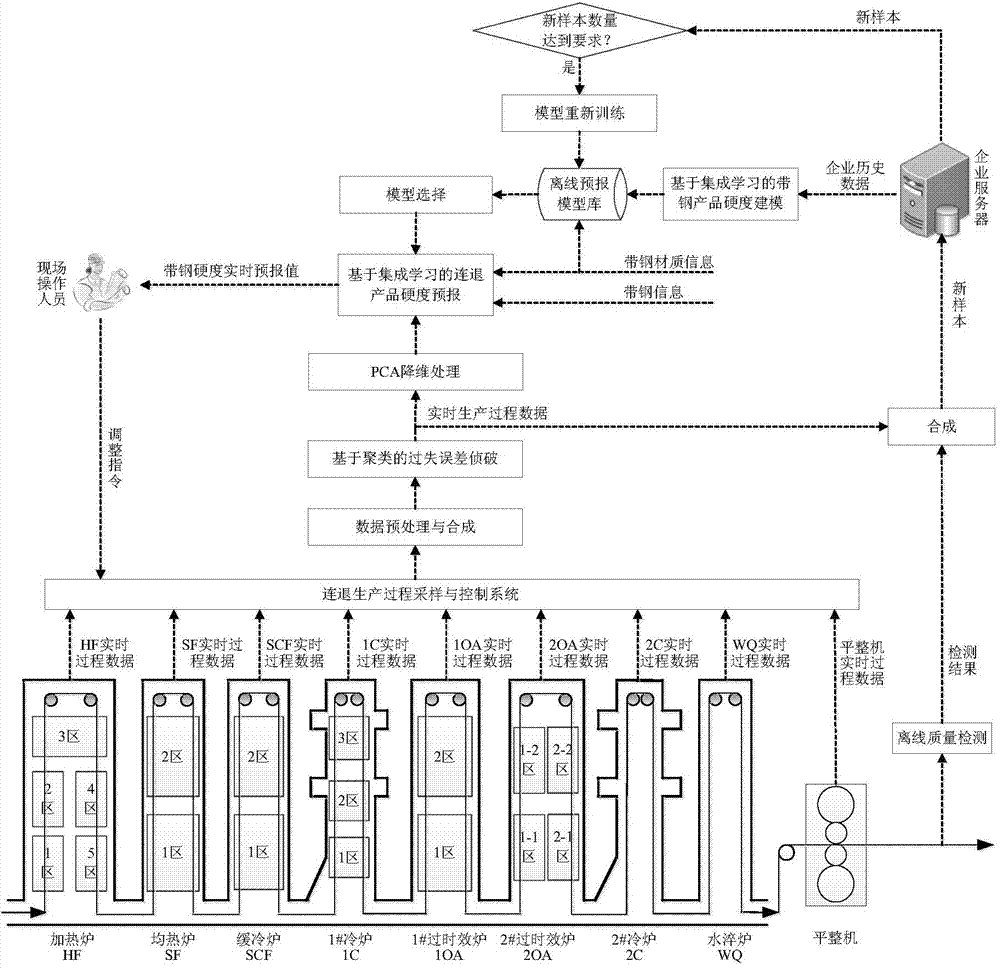

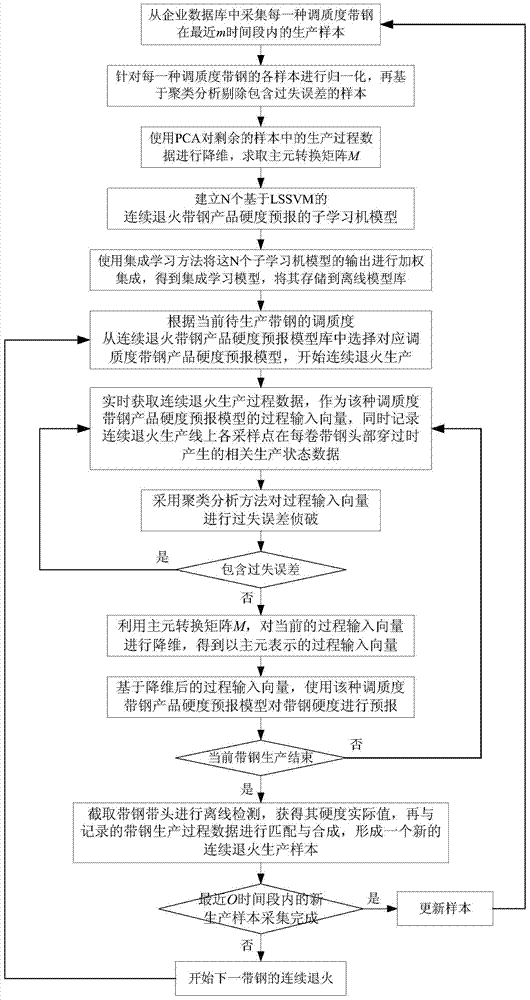

[0044] Continuous annealing production is an important process in cold rolling plants of iron and steel enterprises, such as figure 1 As shown, the continuous annealing production line can be divided into the following nine stages according to the functions: heating furnace (HF), soaking furnace (SF), slow cooling furnace (SCF), 1# cold furnace (1C), 1# overaging furnace ( 1OA), 2# overaging furnace (2OA), 2# cooling furnace (2C), water quenching furnace (WQ), tempering machine. During the production process, the cold-rolled steel strip passes through each furnace of the production line at a certain speed, so that it can complete the heat treatment process such as heating and cooling according to the set annealing process route, thereby eliminating the internal stress caused by the cold-rolled steel strip , and then after leveling, high-qualit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com