Fiber using olefin resin, nonwoven fabric using same, and separator for alkali storage battery

A polyolefin-based resin and non-woven fabric technology, which is applied in the direction of alkaline storage battery, alkaline storage battery manufacturing, battery pack parts, etc., can solve the problems of troublesome process management and complicated process, and achieve the effect of inhibiting self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

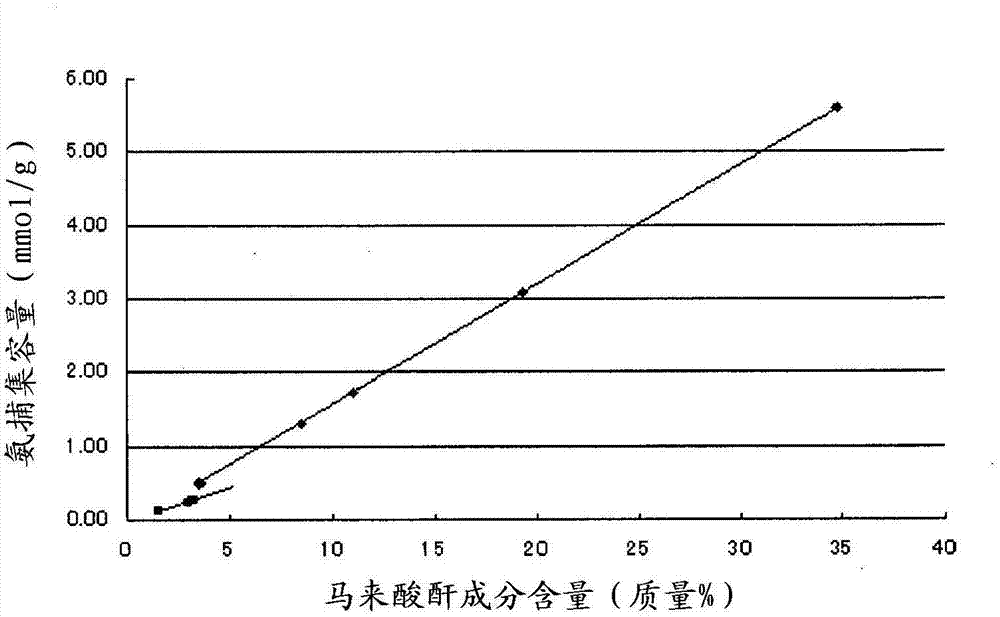

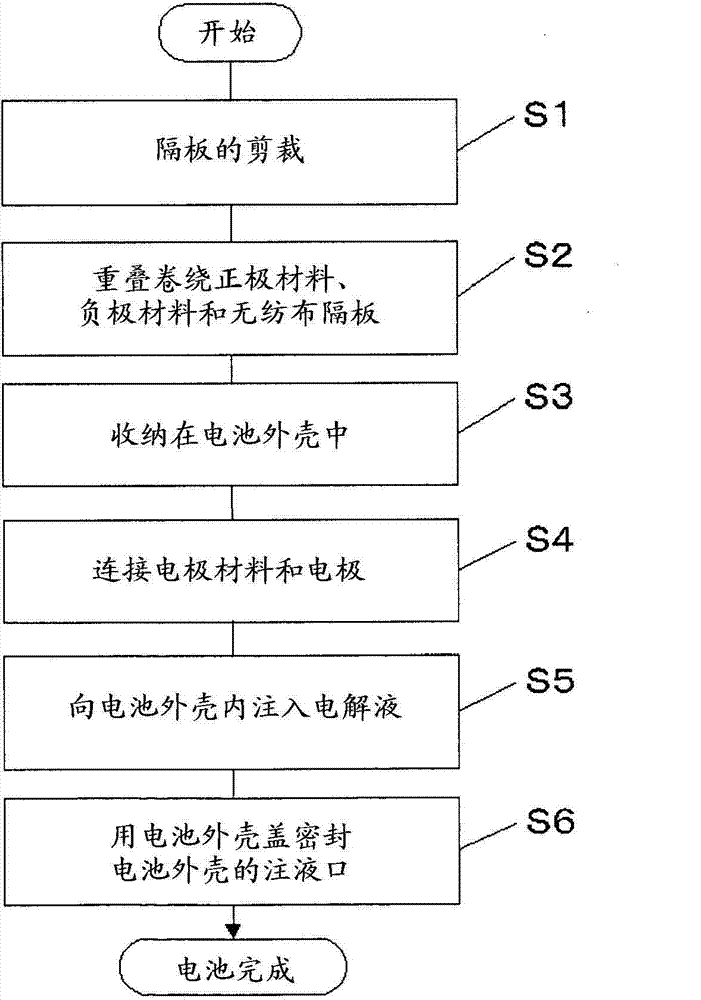

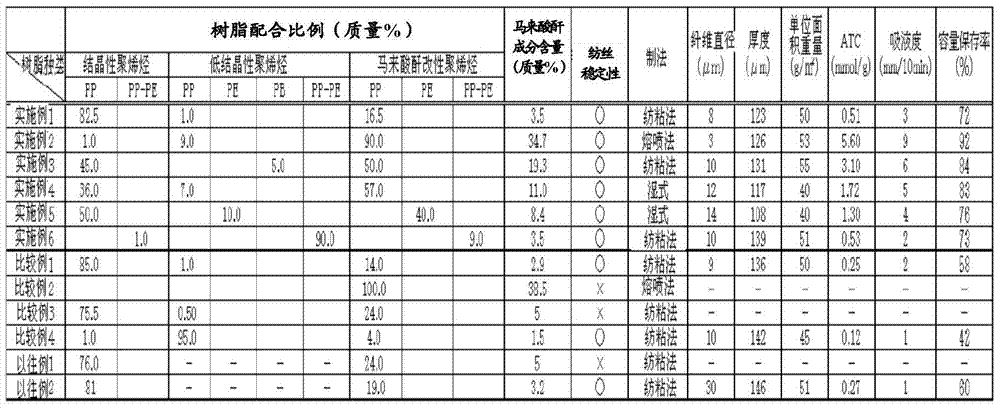

[0121] Crystalline polypropylene as a crystalline polyolefin, low-crystallinity polypropylene (crystallinity: 10%) as a low-crystalline polyolefin, and maleic anhydride crystals were mixed at a mass ratio of 82.5:1.0:16.5. A mixture of maleic anhydride-modified polypropylene (maleic anhydride content: 21.0% by mass) (maleic anhydride content: 3.5% by mass) of a permanent polyolefin was spun and stretched at a temperature of 230°C by a spunbond method. Stretching, thinning, and then thermally bonding fibers through a heating calender to obtain fibers with a diameter of 8 μm, a thickness of 123 μm, and a weight per unit area of 50 g / m 2 non-woven partitions.

[0122] Performance was measured using this nonwoven fabric separator. As a result, the ammonia trapping capacity was 0.51 mmol / g, and the liquid absorption was 3 mm / 10 min. The ammonia trapping capacity was good. The capacity retention rate of the sealed nickel-metal hydride battery using this nonwoven fabric separator ...

Embodiment 2

[0124] Crystalline polypropylene as a crystalline polyolefin, low-crystalline polypropylene (crystallinity: 30%) as a low-crystalline polyolefin, and maleic anhydride crystals were mixed in a mass ratio of 1.0:9.0:90.0. A mixture of maleic anhydride-modified polypropylene (maleic anhydride content: 38.5% by mass) (maleic anhydride content: 34.7% by mass) of a permanent polyolefin was spun and stretched at a temperature of 230°C by a melt blown method. Stretching, thinning, and then thermally bonding fibers through a heating calender to obtain fibers with a diameter of 3 μm, a thickness of 126 μm, and a weight per unit area of 53 g / m 2 non-woven partitions.

[0125] The characteristics were measured using this non-woven fabric separator. As a result, the ammonia trapping capacity was 5.60 mmol / g, and the liquid absorption was 9 mm / 10 min. The ammonia trapping capacity was good. The capacity retention rate of the sealed nickel-metal hydride battery using this nonwoven fabric ...

Embodiment 3

[0127] Crystalline polypropylene as a crystalline polyolefin, low-crystallinity polybutene 1 (crystallinity: 40%) as a low-crystallinity polyolefin, and malay A mixture (content of maleic anhydride: 19.3% by mass) of maleic anhydride-modified polypropylene (content of maleic anhydride: 38.5% by mass) of acid anhydride crystalline polyolefin was spun at 240°C by a spunbond method , Stretching, sheeting, and then thermally bond the fibers through a heating calender to obtain fibers with a diameter of 10 μm, a thickness of 131 μm, and a weight per unit area of 55 g / m 2 non-woven partitions.

[0128] The characteristics were measured using this nonwoven fabric separator. As a result, the ammonia trapping capacity was 3.10 mmol / g, and the liquid absorption was 6 mm / 10 min. The ammonia trapping capacity was good. The capacity retention rate of the sealed nickel-metal hydride battery using this nonwoven fabric separator was 84%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com