Separator for battery

A technology for separators and batteries, which is applied to battery components, circuits, electrical components, etc., can solve the problems of reduced self-discharge reaction inhibition effect, achieve long-term maintenance of battery capacity, improve manufacturing stability, and inhibit self-discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

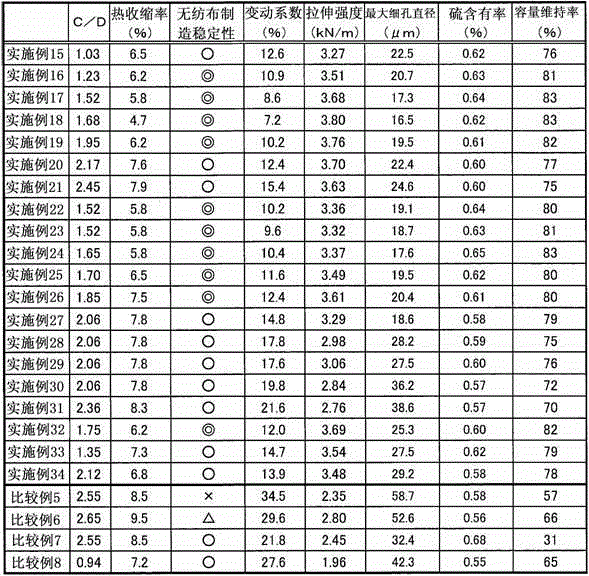

Examples

Embodiment 1)

[0089] Dissociate and disperse 100 parts by mass of core-sheath composite fibers (core / sheath mass ratio 50 / 50, fineness 0.8dtex, fiber length 5mm) in the water of a pulper, and slowly stir with a stirrer to prepare a uniform slurry for papermaking , in the DSC curve of the differential scanning calorimetry analysis of the core-sheath composite fiber, the ratio (C / D) of the melting peak area (C) on the low melting point side to the melting peak area (D) on the high melting point side is 1.06, The core composition is polypropylene and the sheath composition is high density polyethylene. This papermaking slurry was made using a wet papermaking method using a cylinder paper machine, and dried using a Yankee dryer set at 135°C as a hot plate crimping method and a hot air hood installed alongside it. Simultaneously, the sheath portion of the core-sheath composite fiber was thermally melt-bonded to produce a nonwoven fabric having a width of 500 mm. In dry air at 75°C containing su...

Embodiment 2)

[0091] Except in Example 1, the ratio (C / D) of the melting peak area (C) on the low melting point side to the melting peak area (D) on the high melting point side in the DSC curve analyzed using differential scanning calorimetry was 1.27. The core-sheath type composite fiber (core / sheath mass ratio 50 / 50, fineness 0.8dtex, fiber length 5mm) except that the component is polypropylene and the sheath component is high-density polyethylene, is the same as in Example 1 to obtain a weight per unit area of 53.6g / m 2 battery separator. The ratio (A / B) of the melting peak area (A) on the low melting point side to the melting peak area (B) on the high melting point side in differential scanning calorimetry of the obtained battery separator was 1.24.

Embodiment 3)

[0093] Except in Example 1, the ratio (C / D) of the melting peak area (C) on the low melting point side to the melting peak area (D) on the high melting point side in the DSC curve analyzed using differential scanning calorimetry was 1.38. The core-sheath type composite fiber (core / sheath mass ratio 50 / 50, fineness 0.8dtex, fiber length 5mm) except that the component is polypropylene and the sheath component is high-density polyethylene, is the same as in Example 1 to obtain a weight per unit area of 53.7g / m 2 battery separator. The ratio (A / B) of the melting peak area (A) on the low melting point side to the melting peak area (B) on the high melting point side in differential scanning calorimetry of the obtained battery separator was 1.42.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com