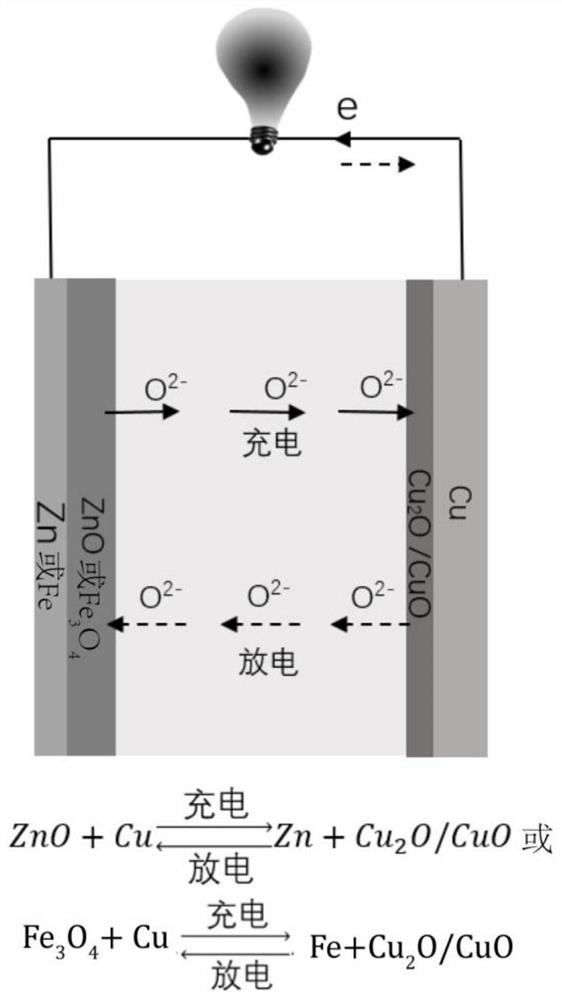

An oxygen ion conductive metal-metal oxide molten salt secondary battery and its preparation method

A technology of oxygen ion conduction and oxide molten salt, applied in secondary batteries, battery electrodes, active material electrodes, etc., can solve the problems of high recycling cost, complex battery structure, low hydrogen evolution potential, etc., and achieve no attenuation of electrochemical performance. , The effect of easy large-scale production and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of the oxygen ion conductive metal-metal oxide molten salt secondary battery of the present embodiment includes the following steps:

[0048] (1) Preparation of iron oxide negative electrode and copper positive electrode:

[0049] Take a clean copper wire and an iron wire with a length of 40 cm and a diameter of 1.5 mm, respectively, bend the copper wire and iron wire into a mosquito coil shape, and then put the iron wire into the muffle furnace, heat it up to 500 °C at 10 °C / min, and keep the temperature for 30 min, take out after cooling to obtain a copper wire positive electrode and an iron oxide negative electrode.

[0050] (2) Preparation of electrolyte:

[0051] Weigh 42 g of KOH and 30 g of NaOH into an alumina crucible and mix evenly, then heat to 300°C on a heating table until NaOH and KOH are melted.

[0052] (3) Assemble the battery:

[0053] Put the copper wire and iron oxide prepared in step (1) into the electrolyte prepared in ste...

Embodiment 2

[0062] The preparation method of the oxygen ion conductive metal-metal oxide molten salt secondary battery of the present embodiment includes the following steps:

[0063] (1) Preparation of copper positive electrode and foamed iron oxide negative electrode:

[0064] Cut a piece of clean copper with a size of 2 × 3 cm, take a piece of foam iron and cut a piece of size 2 × 3 cm, and then put the foam iron into the muffle furnace, heat it up to 500 ° C at 10 °C / min, and keep it warm for 30 min, take it out after cooling to obtain a copper wire positive electrode and a foamed iron oxide negative electrode.

[0065] Step (2) is the same as step (2) in Example 1.

[0066] Step (3) is the same as step (3) in Example 1.

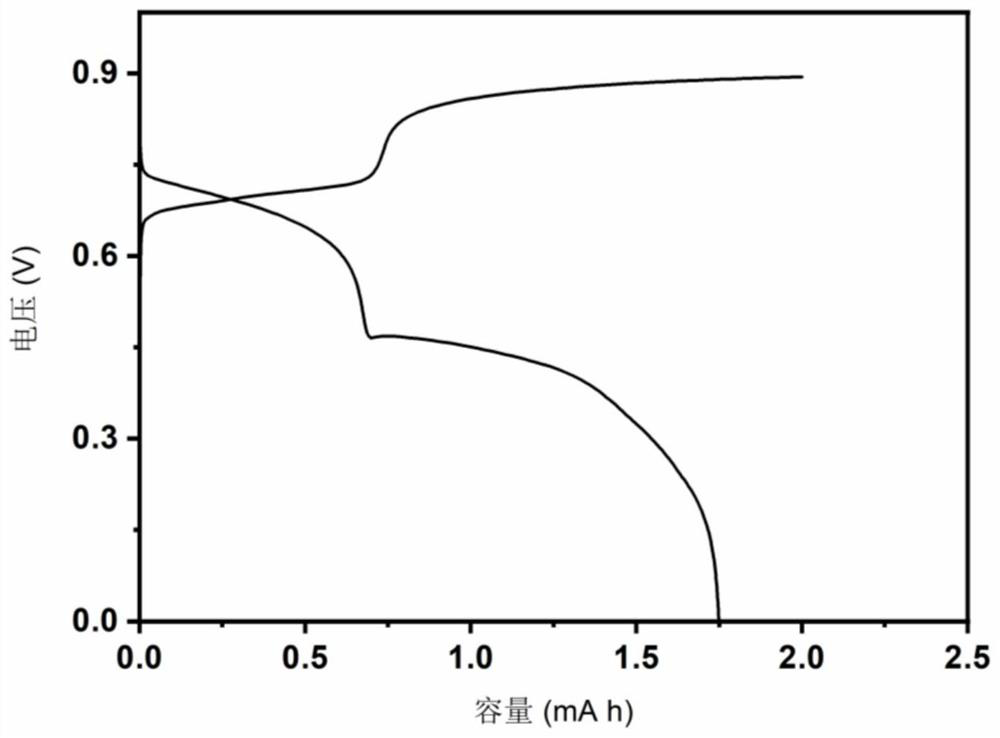

[0067] (4) Battery test:

[0068] The constant current charge-discharge test was performed with a current of 10 mA cm-2.

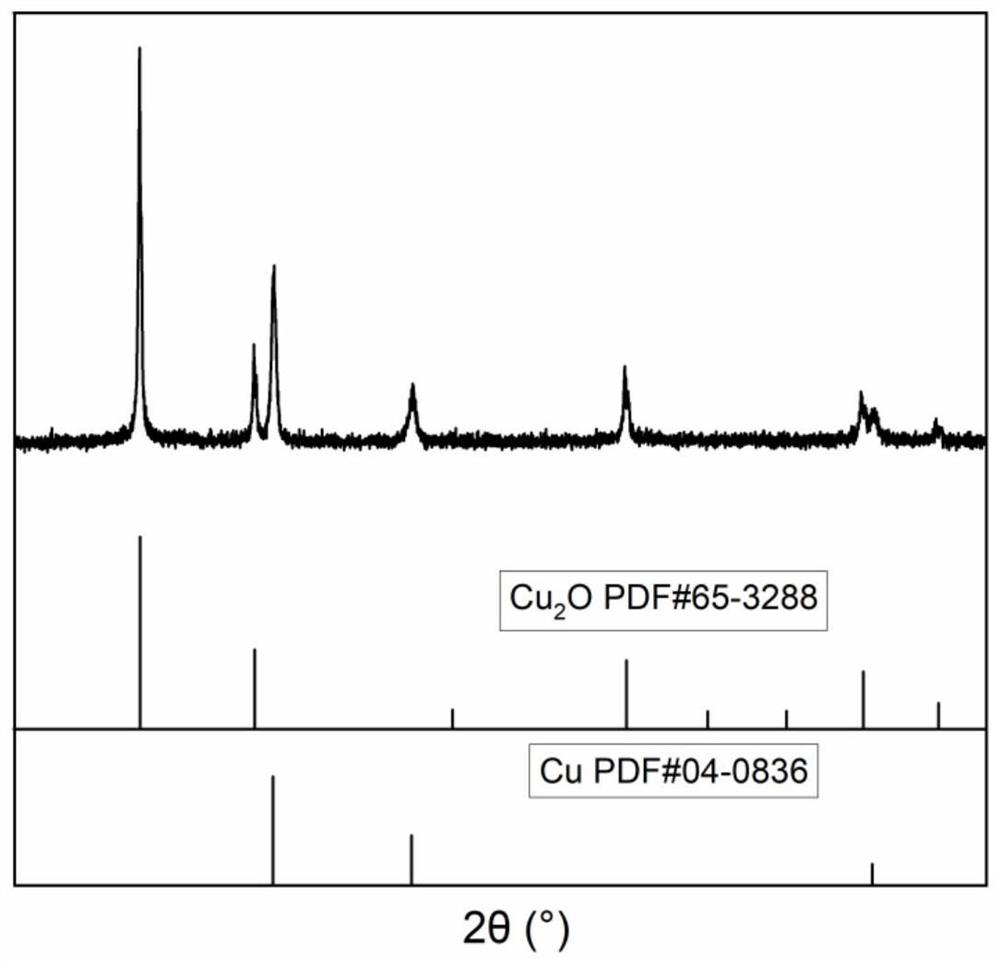

[0069] (5) Electrochemical characterization:

[0070] The foamed iron electrode after 1000 cycles was characterized by scanning electron m...

Embodiment 3

[0075] The preparation method of the oxygen ion conductive metal-metal oxide molten salt secondary battery of the present embodiment includes the following steps:

[0076] (1) Preparation of copper positive electrode and zinc oxide negative electrode:

[0077] Cut a clean copper sheet of 4×6 cm size, and cut a zinc sheet of 4×6 cm size. The surface of the zinc sheet is covered with an oxide film, so it does not need to be treated. Zinc negative.

[0078] (2) Preparation of electrolyte:

[0079]Take 70 g of analytically pure potassium hydroxide and 50 g of analytically pure sodium hydroxide into a square crucible and mix evenly, and heat on a heating table at 300°C until the sodium hydroxide and potassium hydroxide are completely melted to a liquid state.

[0080] (3) Assemble the battery:

[0081] Put the electrolytic sheet prepared in step (1) into the molten salt prepared in step (2), and then rapidly reduce the temperature of the molten salt to 170 °C until the molten sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com