Efficient energy-saving purification and recovery process of tail gas containing volatile organic compounds (VOCs)

A volatile organic compound, high-efficiency and energy-saving technology, used in air quality improvement, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as atmospheric environmental quality decline, human health hazards, etc. The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) The tail gas of a pharmaceutical company contains butyl acetate (immiscible with water). According to the needs of the follow-up section, the butyl acetate in the tail gas needs to be removed to 10mg / m 3 Below, the mass fraction of n-butyl acetate in the raw material tail gas is <1%;

[0025] 2) Using N-methylpyrrolidone as a solvent to purify the tail gas, the suction temperature of the gas to be treated is 25°C, and the content of n-butyl acetate in the liquid entering the absorption tower is less than 1%;

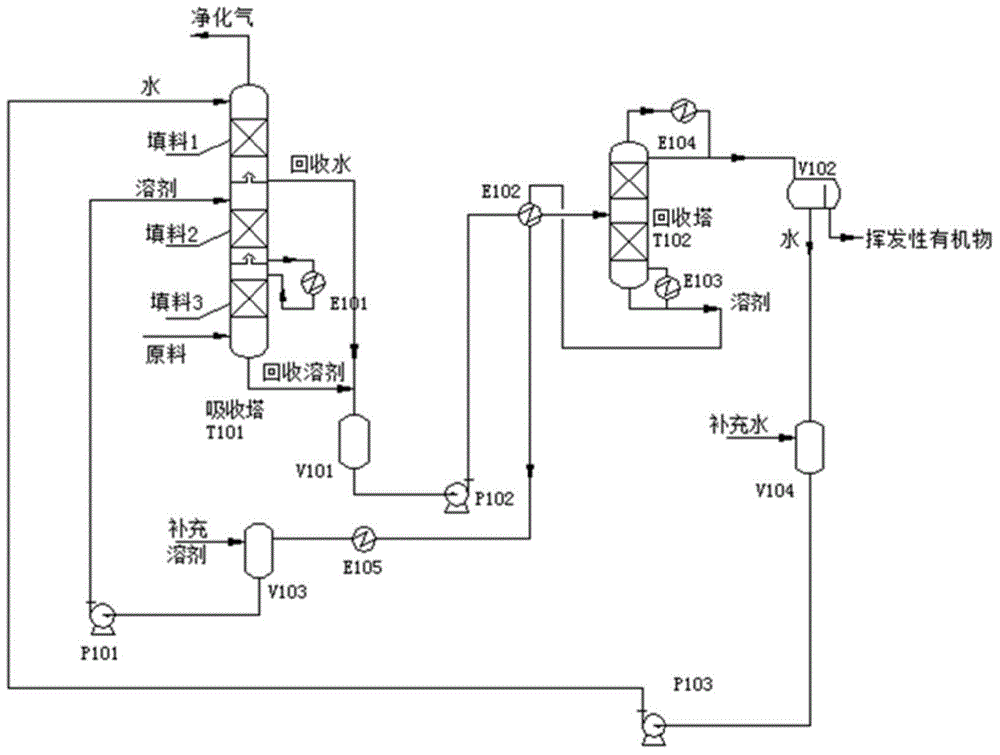

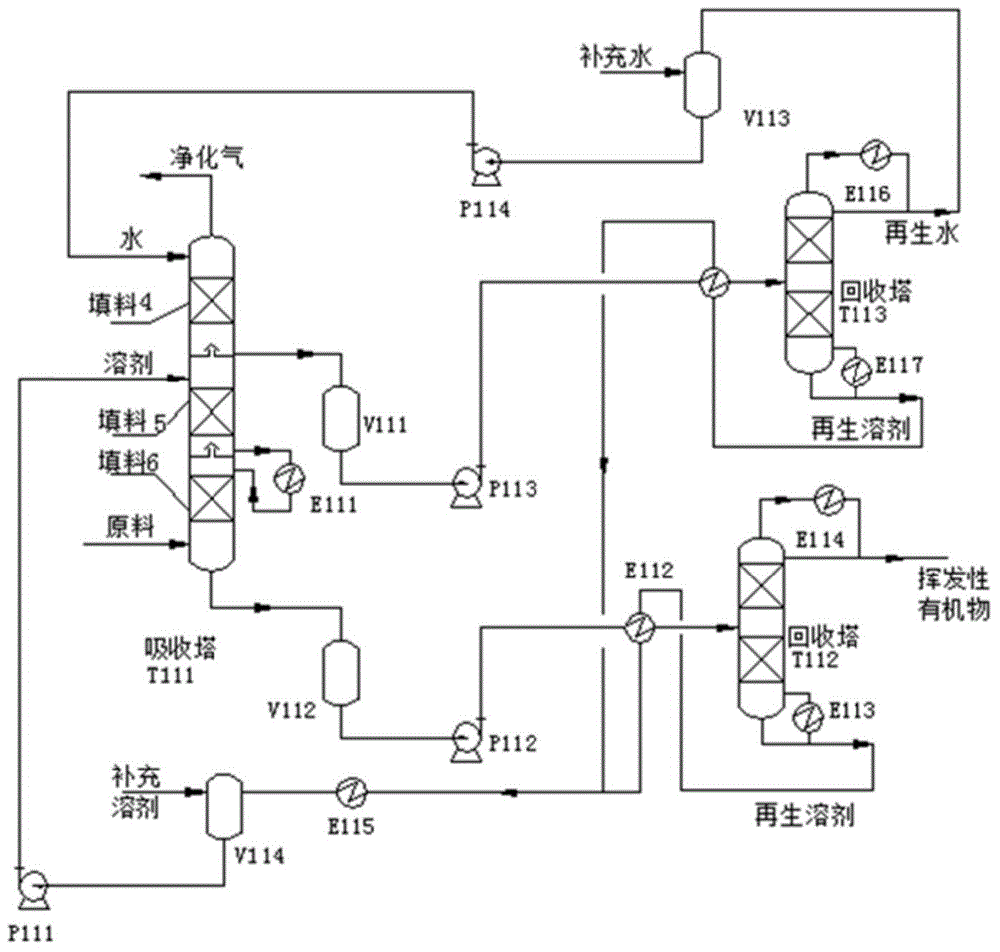

[0026] 3) if figure 1 As shown, the raw material tail gas enters the absorption tower T101 from the raw material inlet at the bottom of the absorption tower. The operating conditions of the absorption tower T101 are normal temperature and normal pressure. In T101, water enters from the water inlet pipe located at the upper end of packing 1 of absorption tower T101, and in the absorption tower T101, it is in reverse contact with the tail gas of raw materials. M...

Embodiment 2

[0031] 1) The gas source for treatment is the same as in Example 1, and the absorption solvent is N-methylpyrrolidone and N-formylmorpholine, which are mixed at a mass ratio of 1:1 to prepare a mixed solvent to purify the tail gas. The suction temperature of the gas to be treated is 28°C. The content of butyl acetate in the liquid entering the absorption tower is less than 1%;

[0032] 2) After purification, the content of butyl acetate in the purified gas exiting the absorption tower is reduced to 5 mg / m 3 the following;

[0033] 3) Recovery tower T102, the temperature at the bottom of the tower is 171°C, the temperature at the top of the tower is 45°C, the reflux ratio is 4, the operating pressure is 0.03MPA (A), and other operating conditions are the same as in Example 1.

Embodiment 3

[0035] 1) The tail gas of a chemical company contains toluene and xylene. According to the emission requirements, the toluene and xylene in the tail gas should be removed to 10mg / m 3 , the mass fraction of toluene and xylene in the raw material tail gas is <1%;

[0036] 2) Using N-methylpyrrolidone as a solvent to purify the tail gas, the suction temperature of the gas to be treated is 25°C, and the content of toluene and xylene in the liquid entering the absorption tower is <1%;

[0037] 3) The raw material tail gas enters the absorption tower T101 from the raw material inlet 1 at the bottom of the tower. The condition of the absorption tower T101 is normal temperature and normal pressure operation, and the solvent used for purifying the tail gas enters the absorption tower T101 through the solvent pipeline located at the upper end of the packing 2 of the absorption tower. , water enters from the water inlet pipe at the upper end of the filler 1 of the absorption tower T101, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com