Shale crusher dust collector

A technology of dust removal device and pulverizer, which is applied in the direction of removing smoke and dust, swirl device, device whose axial direction can be reversed, etc., and can solve the problem of affecting the operation of the staff, not having a dust removal device, and the air contains a large amount of dust, etc. problems, to achieve the effect of collection and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings by means of specific embodiments:

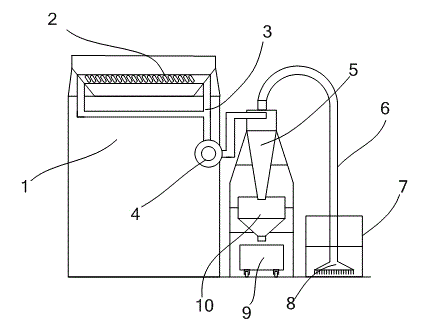

[0013] Such as figure 1 The dust removal device of the shale pulverizer shown includes a dust suction pan 2 arranged on the upper edge of the feed port of the pulverizer 1, a negative pressure fan 4, a cyclone dust collector, and a tailings collection box 7. The dust suction pan 2 is provided with a circle of dust suction The diameter of the dust suction hole is 4mm. The dust suction plate 2 is connected to the inlet of the cyclone dust collector 5 through the dust suction pipe 3. The negative pressure fan 4 is arranged on the dust suction pipe 3. The bottom of the cyclone dust collector 5 is connected to a fine material collection box. 10. A tailing pipe 6 is arranged on the top, and the tailing pipe 6 passes into the tailing collection box 7 filled with water, and the end of the tailing pipe 6 is arranged as a flat pipe 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com