Self-driven liquid metal machine and application thereof

A liquid metal, self-driven technology, applied in the direction of micro-manipulators, manipulators, manufacturing tools, etc., can solve the problems of increasing machine size, short motion life, low absolute motion speed, etc., to achieve expanded application range, simple and easy design, and broad The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

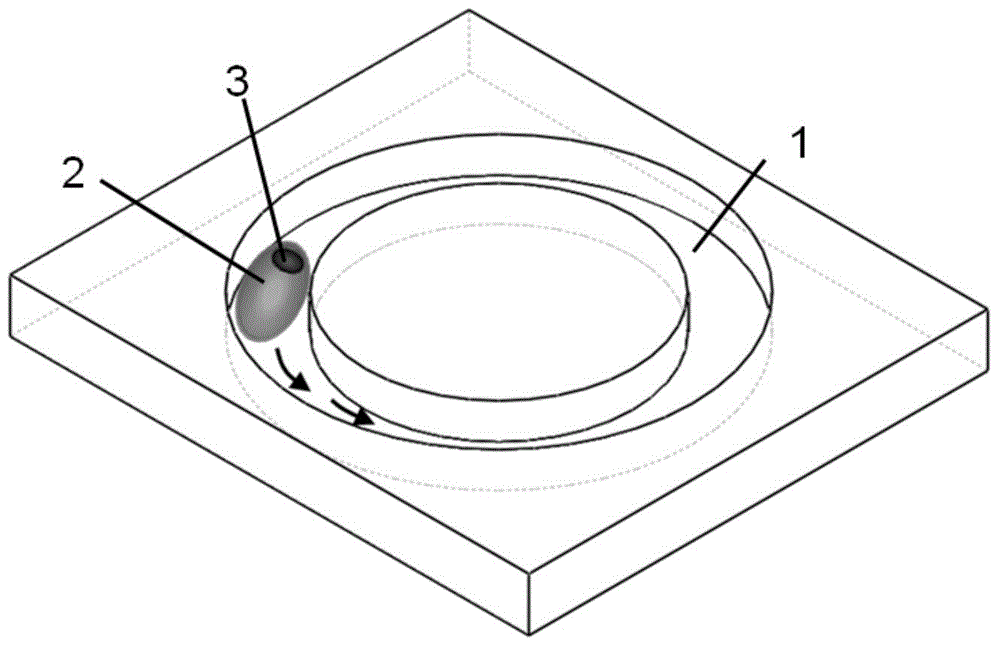

[0026] Such as figure 1 As shown, this embodiment is described by taking the self-propelled liquid metal machine in the annular channel to automatically drive its own movement as an example.

[0027] 1. Prepare the aqueous solution 1 with a specific concentration, raise the temperature of the aqueous solution 1 water bath to 60°C to speed up the opening of the liquid metal drive, and then inject it into the annular channel.

[0028] 2. Use a syringe to inject a certain amount of liquid metal material 2 into the annular channel, then use tweezers to grab a small piece of aluminum sheet 3 and place it in the aqueous solution 1, and put the aluminum sheet 3 in contact with the liquid metal material 2, so that the aluminum sheet 3 Perform electrochemical corrosion reaction with aqueous solution 1. After contacting for a certain period of time, the aluminum sheet 3 is adsorbed on the liquid metal material 2, and the reaction speed is accelerated. With the acceleration of the react...

Embodiment 2

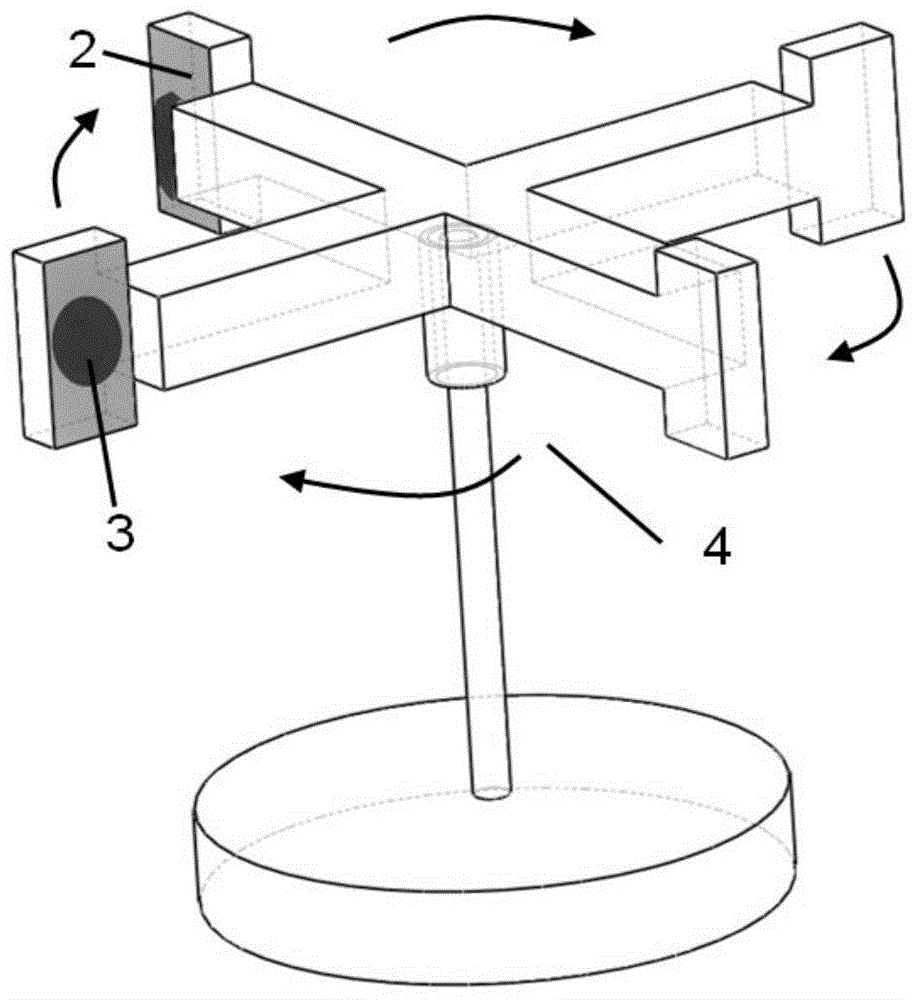

[0030] Such as figure 2 As shown, this embodiment is described by taking the self-propelled liquid metal machine liquid metal to drive the movement of the small horizontal rotor 4 as an example.

[0031] 1. Prepare the aqueous solution 1 with a specific concentration, raise the temperature of the aqueous solution 1 to about 60°C in a water bath, and then pour the aqueous solution 1 into the container.

[0032] 2. Place the small horizontal rotor 4 in the container.

[0033]3. A certain amount of liquid metal material 2 is added dropwise on the copper sheet attached to the horizontal rotor 4, and the liquid metal adheres to the copper sheet after a few minutes by utilizing the corrosion characteristics of the liquid metal.

[0034] 4. Use tweezers to pick up a small piece of aluminum sheet 3, and put the aluminum sheet 3 in contact with the liquid metal material 2. Under the joint action of the aqueous solution 1 and the liquid metal material 2, the aluminum sheet 3 begins to...

Embodiment 3

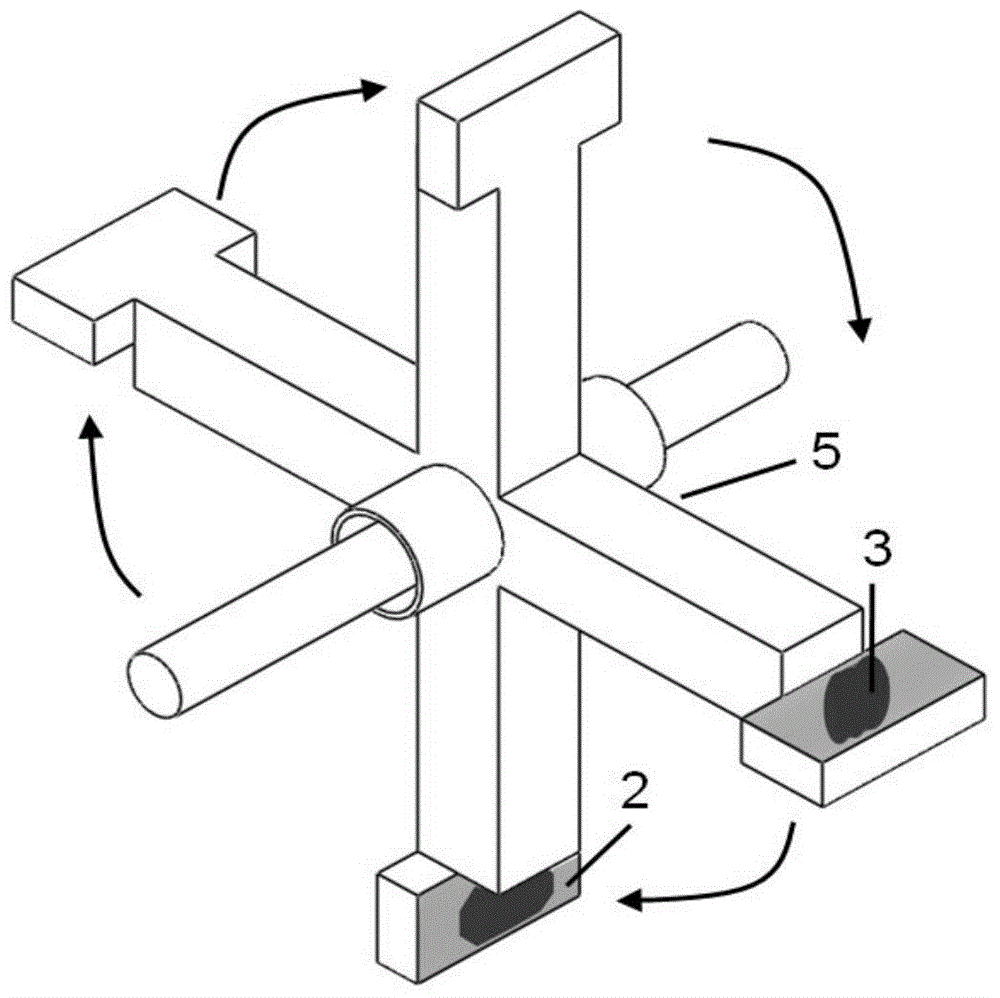

[0036] Such as image 3 As shown, this embodiment is described by taking the self-propelled liquid metal machine as an example to drive the small vertical rotor 5 to move.

[0037] 1. Prepare an aqueous solution with a specific concentration, raise the temperature of the aqueous solution water bath to about 60°C, then pour the solution 2 into the container, and place the small vertical rotor 5 in the container.

[0038] 2. A certain amount of liquid metal material 2 is added dropwise on the copper sheet attached to the rotor, and the liquid metal material 2 adheres to the copper sheet after a few minutes by utilizing the corrosion characteristics of liquid metal.

[0039] 3. Use tweezers to pick up a small piece of aluminum sheet 3, and put the aluminum sheet 3 in contact with the liquid metal material 2. Under the joint action of the aqueous solution 1 and the liquid metal material 2, the aluminum sheet 3 begins to undergo a chemical reaction, generating bubbles, and Drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com