A kind of hydrophilic slump-retaining mineral composite fiber particle and its preparation method

A composite fiber and hydrophilic technology, which is applied in the field of mineral composite fibers, can solve the problems of reduced adding efficiency, low automation rate, and low production efficiency, so as to slow down slump loss, realize production automation, and ensure pumping and pouring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The mass ratio of hydrophilic mineral composite fiber and sodium lignin sulfonate is 1:0.024, mixed for 12 minutes in a dry environment with a temperature of 28 degrees Celsius, and the mixed mixture is placed in an environment with a humidity of 80% for 1.5 hours , the mixture is made into mixture granules, the diameter of the obtained mixture granules is 5 mm, the density of the mixture granules is 0.8 tons per cubic meter, and the moisture content of the mixture granules is 5%.

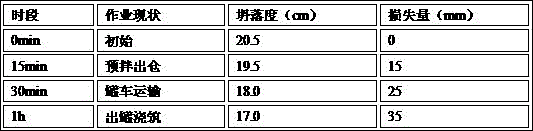

[0046] Three tests were done respectively, the first one used ester sulfonate concrete directly, the second one used ester sulfonate concrete mixed with the hydrophilic mineral composite fiber with patent No. 201010605747.1, and the third one used The ester group sulfonate concrete of the hydrophilic slump-retaining mineral composite fiber particles of the embodiment; the slump in different time periods and various performance indicators of the final concrete were recorded respectively.

[004...

Embodiment 2

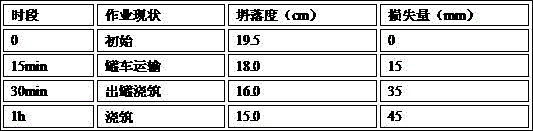

[0058] The mass ratio of hydrophilic mineral composite fiber and sodium lignosulfonate is 1:0.021, mixed for 15 minutes in a dry environment with a temperature of 25 degrees Celsius, and the mixed mixture is made in a water mist environment with a temperature of 25 degrees Celsius Mixture particles, the water mist environment is sprayed by the flow rate of the spray device within the range of 30 milliliters per second; the spray device performs intermittent spraying, the number of sprays is within the range of 6 times, and the single spray time is 10 seconds. Be 70 seconds; The diameter of gained mixture particle is 8 millimeters, and the density of mixture particle is 0.9 tons per cubic meter, and the moisture content of mixture particle is 4%.

[0059] For the fourth test, the ester sulfonate concrete mixed with the hydrophilic slump-retaining mineral composite fiber particles of this embodiment was used; the slump in different time periods and the performance indicators of t...

Embodiment 3

[0067] The mass ratio of hydrophilic mineral composite fiber to sodium lignosulfonate is 1:0.026, mixed in a dry environment at a temperature of 30 degrees Celsius for 10 minutes, and the mixed mixture is placed in an environment with a humidity of 85% for 1.5 hours , the mixture is made into mixture granules, the diameter of the obtained mixture granules is 6 mm, the density of the mixture granules is 0.78 tons per cubic meter, and the moisture content of the mixture granules is 6%.

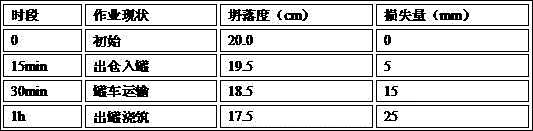

[0068] In the fifth test, ester sulfonate concrete mixed with the hydrophilic slump-retaining mineral composite fiber particles of this embodiment was used; the slump in different time periods and the performance indicators of the final concrete were recorded respectively.

[0069] (Table 7 is the slump record table of the fifth test, and Table 8 is the performance indicators of the concrete obtained in the first, second and fifth tests)

[0070] period of time Job status Slump (cm)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com