A kind of manufacturing device and method of ecological nutritional blanket base for breeding

A technology for manufacturing devices and nutrition, which is applied in the direction of fertilization devices, fertilizer mixtures, fertilizer forms, etc., can solve the problems of soil eutrophication surface loss, easy to produce irritating odor, and land barren nutrition, etc., to achieve long-lasting fertilizer effect and realize large-scale Large-scale industrial production and the effect of avoiding impoverishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

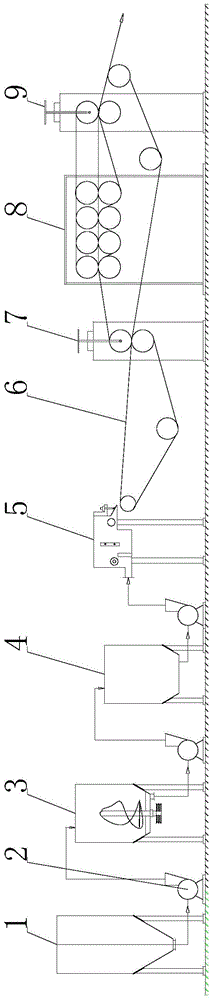

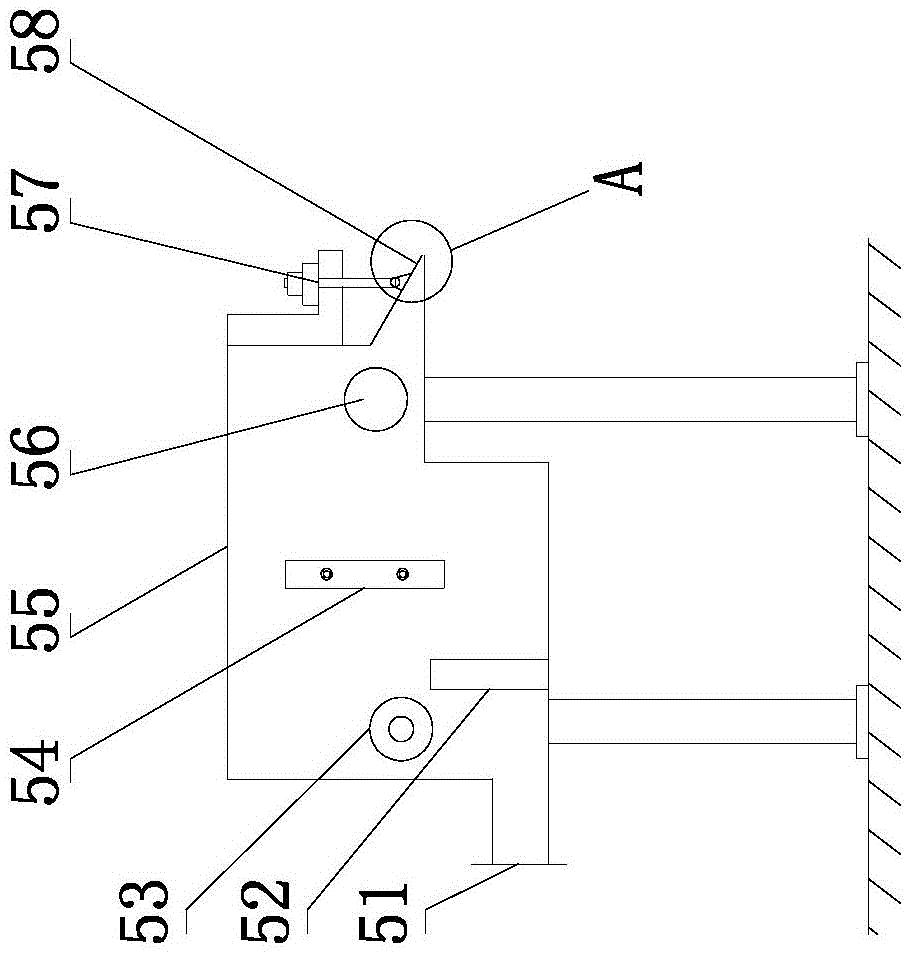

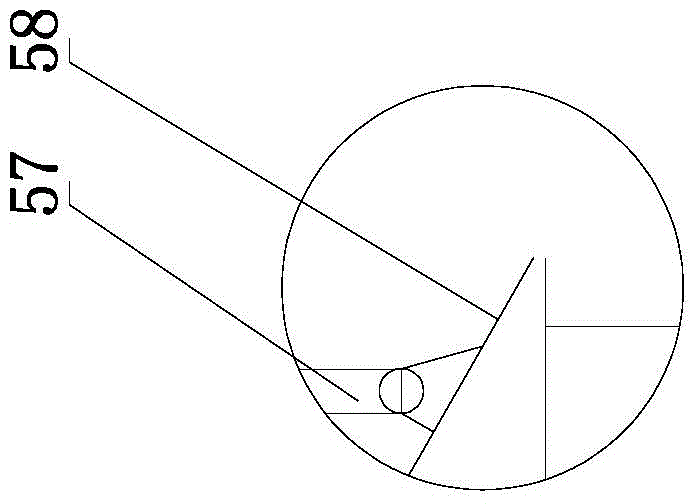

[0031] Such as figure 1 Shown, a kind of manufacturing device of breeding eco-nutritional blanket base comprises deodorizing and detoxifying tank 1 for pretreatment, mixing agitator 3 for disintegration and uniform mixing, adjustment pool 4 for adjusting concentration, and Homogenization box for uniform concentration and flow control 5, dehydrator for preliminary dehydration treatment 6, simple press for pressing 7, drying device for drying moisture 8, cutting for cutting Device 9, the deodorization and detoxification tank 1, the mixing agitator 3, the regulating tank 4, and the homogenizing tank 5 are connected in sequence through the mud delivery pump 2 and pipelines, and the dehydrator 6 is arranged on the homogenizing At the outlet of the box 5, the simple press 7 is arranged at the outlet of the dehydrator 6, the drying device 8 is arranged at the outlet of the simple press 7, and the cutting device 9 It is arranged at the discharge port of the drying device 8 .

[0032...

Embodiment 2

[0039] A kind of method adopting described device to manufacture breeding ecological nutrition blanket, comprises steps:

[0040] (1) Use 0.05-0.1% photochemical bacteria and 0.01-0.03% chelating agent to puff and ferment industrial sludge or municipal domestic sludge in deodorization and disinfection tank 1, deodorize and sterilize the pulp liquid-like substance, the processing time is 5-7 days;

[0041] (2) Transport the treated pulpy fluid material into the mixing agitator 3 through the delivery pump 2 to neutralize the waste paper fibers and nutrients and disintegrate and mix them evenly;

[0042](3) Use the delivery pump 2 to send the mixed material in the mixing agitator 3 to the regulating tank 4, and add water to dilute it into a slurry with a concentration of 0.3-0.5%;

[0043] (4) Pump the slurry obtained in step (3) into the homogenization box 5 to mix evenly, and conduct preliminary dehydration treatment through the dehydrator 6 with a certain pressure and through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com