Preparation method and application of PDMS (polydimethylsiloxane)-magnetic nano-particle composite optical film

A magnetic nanoparticle, PDMS- technology, applied in optics, optical components, instruments, etc., can solve the problem of very little exploration of micro-scale MRE optical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

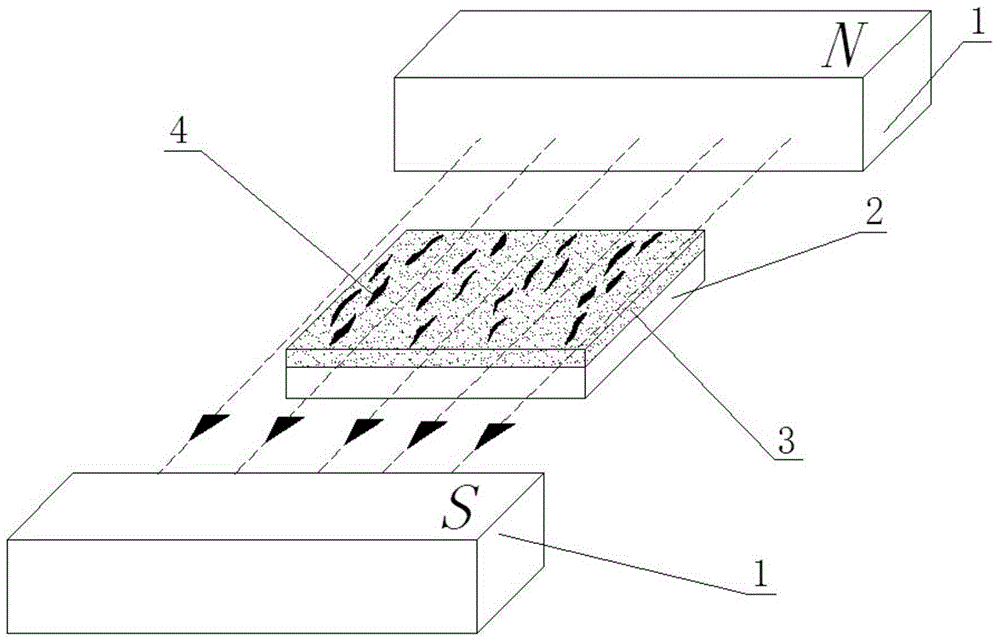

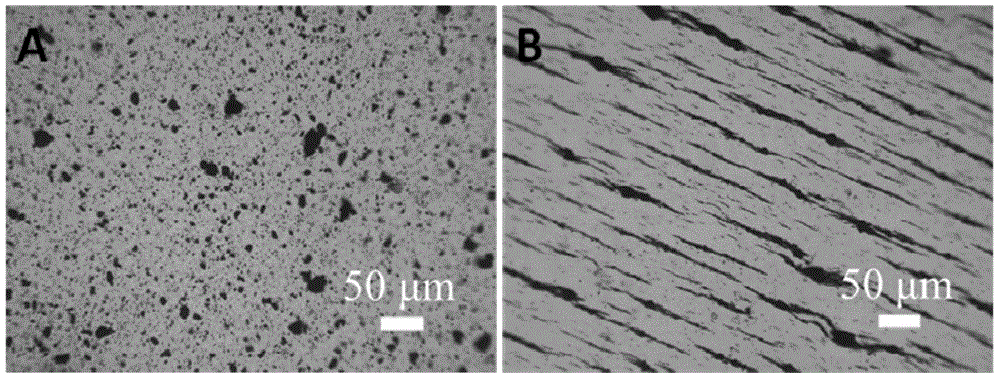

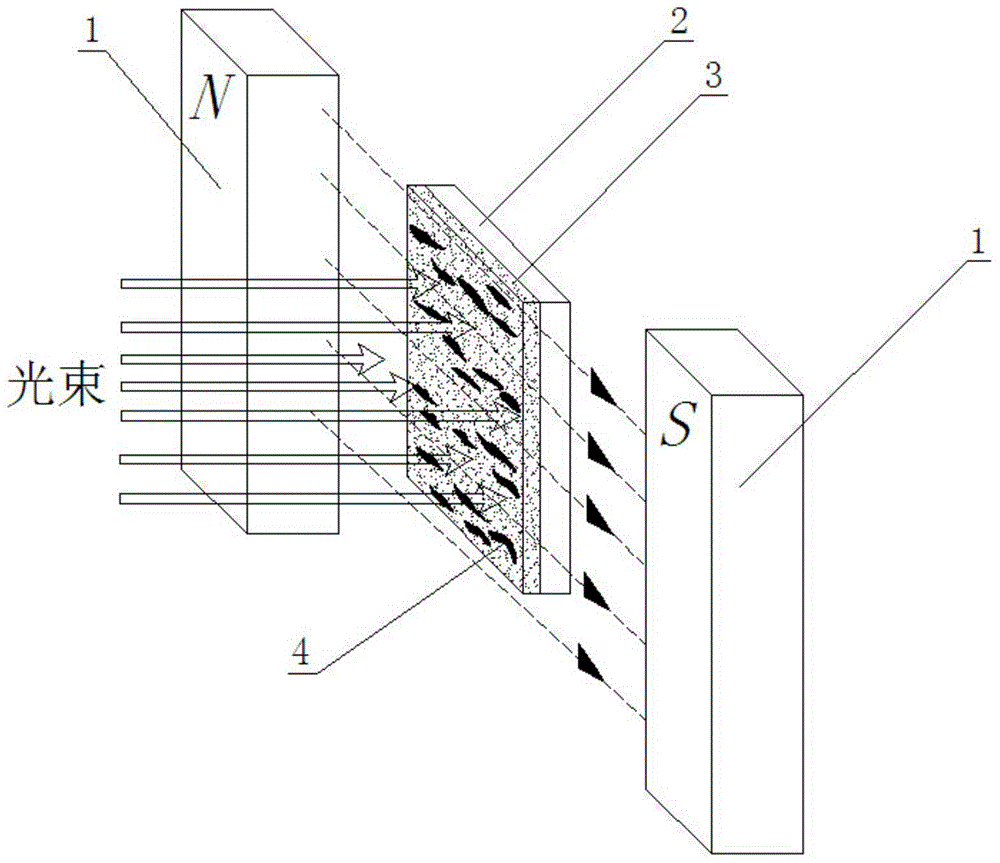

[0029] 1. The preparation process of a new polymer-based nanocomposite optical film with magnetorheological elastomer properties:

[0030] (1) Preparation of PDMS-magnetic nanoparticles mixed solution

[0031] PDMS is a silicone rubber elastomer widely used in the field of microelectromechanical systems. It has high optical transparency, stable physical and chemical properties, and biocompatibility. The PDMS used in the present invention is formed by mixing a prepolymer and a curing agent (Dow Corning Sylgard 184). The preparation of PDMS-magnetic nanoparticle mixed solution comprises the following steps:

[0032] 1) Mix the PDMS prepolymer and curing agent (DowCorning Sylgard 184) at a weight ratio of 10:1, stir evenly, put the mixture into a 40KHz ultrasonic oscillator and vibrate for 5 minutes to remove bubbles, and at the same time promote its further thorough mixing;

[0033] 2) Mix the mixture obtained in step 1) with chloroform at a weight ratio of 1:1 to form a mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com