Anti-corrosion and anti-rust pigment

An anti-corrosion, anti-rust and pigment technology, applied in the field of pigments, can solve the problems of poor anti-rust effect of pigments and insufficient color of pigments, and achieve the effects of improving color and luster, improving adhesion and delaying aging.

Inactive Publication Date: 2015-04-22

于芳

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The antirust effect of the pigment of this invention is poor, and the color and luster of the pigment is not bright enough

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

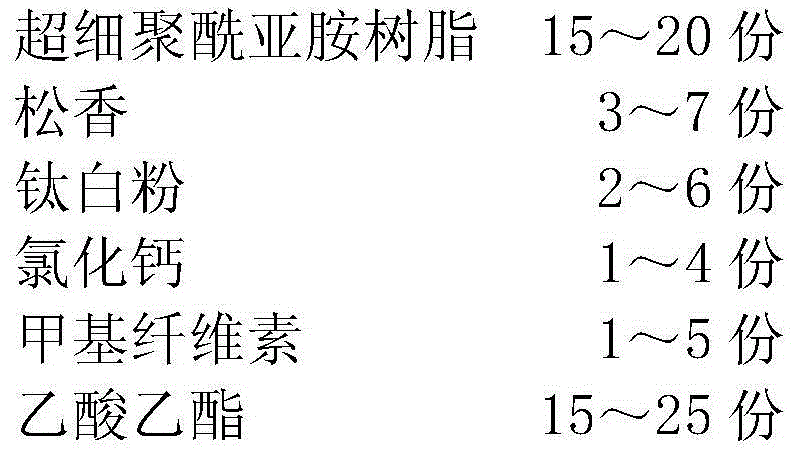

[0032] The anticorrosion and antirust pigment is made from the following raw materials in parts by weight:

[0033]

Embodiment 2

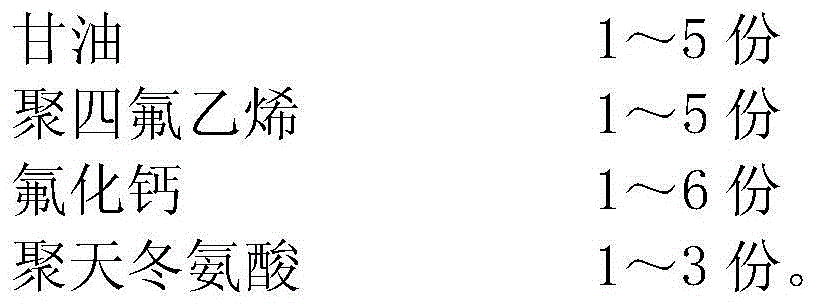

[0035] The anticorrosion and antirust pigment is made from the following raw materials in parts by weight:

[0036]

[0037]

Embodiment 3

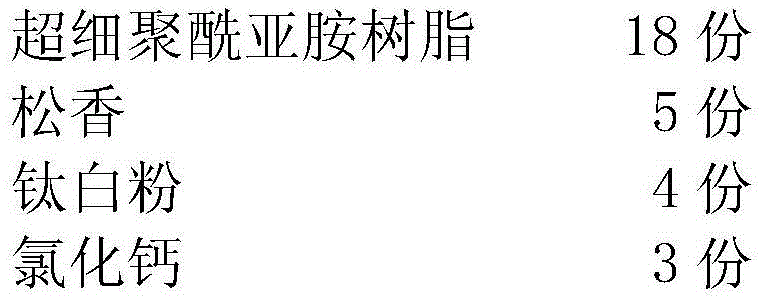

[0039] The anticorrosion and antirust pigment is made from the following raw materials in parts by weight:

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of pigment, and particularly relates to anti-corrosion and anti-rust pigment. The anti-corrosion and anti-rust pigment comprises, by weight, 15-20 parts of ultrafine polyimide resin, 3-7 parts of rosin, 2-6 parts of titanium dioxide, 1-4 parts of calcium chloride, 1-5 parts of methylcellulose, 5-25 parts of ethyl acetate, 1-5 parts of glycerinum, 1-5 parts of Teflon, 1-6 parts of calcium fluoride and 1-3 parts of poly aspartic acid. The anti-corrosion and anti rust is good in performance and superior to prior pigment. The aging resistance is achieved, the service life is prolonged, and the adhesive force is preferable. Compared with the prior pigment, the color and the luster are better, and the glowing effect can be achieved at night.

Description

technical field [0001] The invention belongs to the technical field of pigments, in particular to an anti-corrosion and anti-rust pigment. Background technique [0002] Pigment is a powdered substance used for coloring. It is insoluble in water, oil, resin, organic solvent and other media, but can be evenly dispersed in these media and can make the media color, and has a certain covering power. Existing pigments have single functions and cannot meet the needs of traditional pigments. The raw material cost of pigments is relatively high, the production process is relatively complicated, and pigments generally do not have multiple functions such as anti-rust and anti-corrosion. This is the defect of traditional pigments. At the same time, traditional antirust pigments, such as lead silicochromate, zinc chromate, strontium chromate, red lead, calcium perleadate, yellow lead, lead powder, etc., generally contain elements such as lead, chromium and cadmium, although the antirust...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D7/12C09D5/08

CPCC09D5/082

Inventor 于芳

Owner 于芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com