Method for preparing industrial alcohol by fermenting cane molasses through lactobacillus casei

A technology of Lactobacillus casei and sugarcane molasses, which is applied in the recycling of industrial waste and in the field of microorganisms to achieve high output rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

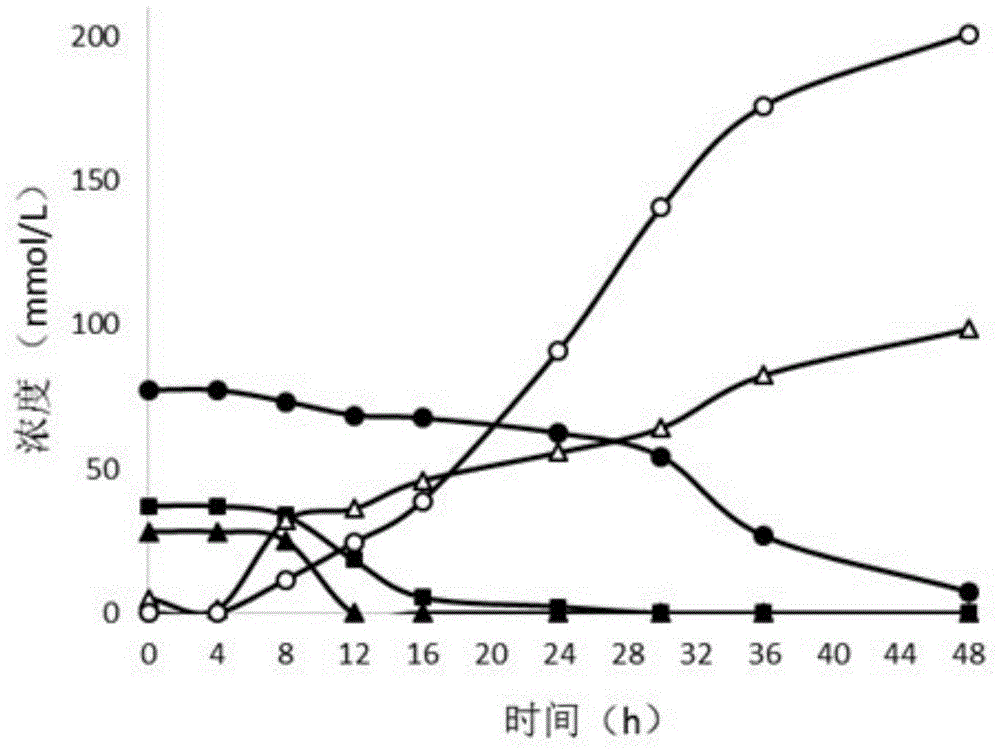

[0023] The specific embodiment one: a kind of method utilizing Lactobacillus casei to ferment sugarcane molasses of the present embodiment to prepare industrial ethanol, it is carried out according to the following steps:

[0024] 1. Pick Lactobacillus casei from the cryopreserved glycerol tube and insert it into the MRS liquid medium, and cultivate it at 37°C for 24 hours; wherein, the pH of the MRS liquid medium is 6.0;

[0025] 2. For the strains cultivated in step 1, the concentration is 1×10 8 Insert CFU / mL into sterilized sugarcane molasses solution, and incubate at 37°C for 24-30 hours;

[0026] 3. Fill the sugarcane molasses fermentation liquid into the fermenter, seal all the inlets and outlets, sterilize and cool, and set aside;

[0027] 4. For the strains cultivated in step 2, the concentration is 1×10 8 Connect CFU / mL to the fermenter in step 3 for fermentation and culture, set up an automatic pH constant system to keep the pH value constant at 5.95-6.05, set the...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that: NaOH solution and HCl solution are used to adjust the pH value of the molasses fermentation liquid to 6.0. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the lye used to keep the pH value constant is NaOH solution, and the acid solution is HCl solution. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com