Method for quickly separating Synechocystis cells and mineralization products thereof

A mineralization product, Synechocystis technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganism measurement/inspection, etc., can solve the damage of mineral surface structure, and it is difficult to observe the micro-morphology of mineral surface in detail. Appearance and other issues, to achieve rapid results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

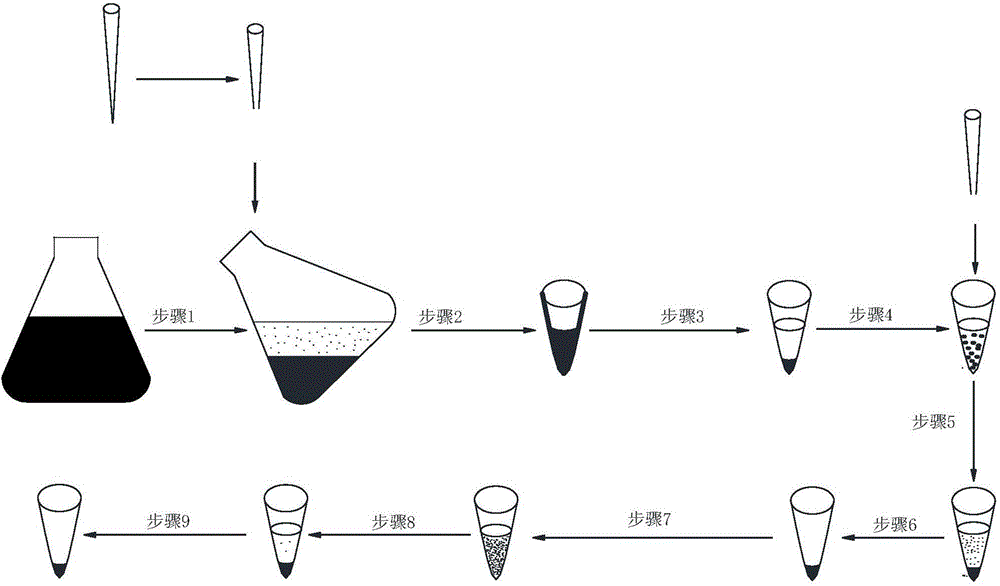

[0040] In the present invention, after the induction of minerals by Synechocystis is completed, the Synechocystis cell culture solution is placed in an Erlenmeyer flask, and the Erlenmeyer flask containing the Synechocystis cell culture solution is placed in an ultrasonic cleaner to vibrate at a frequency of 35W. The time is 360s;

[0041] Put the shaken Synechocystis culture solution on the bracket obliquely. The purpose of the oblique placement is to make the mineral precipitation gather in a certain area at the bottom of the Erlenmeyer flask. After standing for about 10 minutes, it can be observed that there are a large amount of minerals at the bottom precipitation;

[0042] In order to prevent the tip of the pipette from being too sharp and puncture the mineral deposits, install the pipette with the tip of the pipette removed and absorb 1 mL of the mineralized sediment of Synechocystis converging at the bottom, place it in a 1.5 mL centrifuge tube, and centrifuge at 12,00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com