High-quality non-quenched and tempered seamless steel pipe for drilling and its manufacturing method

A technology of seamless steel pipe and manufacturing method, which is applied in the field of high-quality non-quenched and tempered seamless steel pipe for drilling and its manufacturing field, can solve the problems of inability to meet the requirements of deep drilling in the crust and the seabed, low elongation, low overall strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

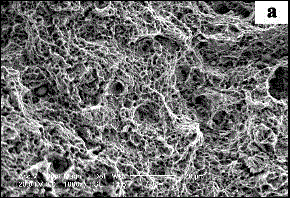

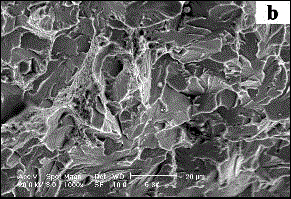

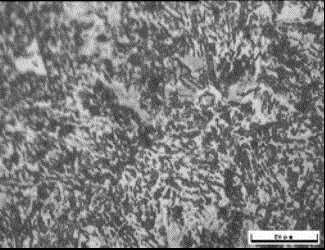

[0041] Example 1: The high-quality non-quenched and tempered seamless steel pipe for drilling in this example is composed of the following components by weight percentage: C: 0.36%, Si: 0.28%, Mn: 1.48%, Mo: 0.26%, V : 0.07%, Ti: 0.022%, Alt: 0.016%, P: 0.010%, S: 0.006%, N: 75ppm, H: 1.5ppm; O: 25ppm, As+Sn+Pb+Sb+Bi=0.038%, the rest is iron Fe and unavoidable The metallographic structure is uniform and fine granular bainite structure, the drilling pipe specification: 70.2×4.9×3300mm, its performance: tensile strength Rm: 1140MPa, yield strength Rp0.2: 970MPa, elongation A: 18% , Longitudinal impact energy A KU2 : 96J.

[0042] The manufacturing process of the present embodiment is as follows:

[0043] (1) Electric furnace smelting: add molten iron and steel scrap to realize pre-de-P and initial composition adjustment to obtain primary molten steel, C: 0.56%, P: 0.060%, S: 0.070%;

[0044] (2) Refining in LF furnace: send the molten steel from primary smelting to LF furnace...

Embodiment 2

[0052] Example 2: The high-quality non-quenched and tempered seamless steel pipe for drilling in this example is composed of the following components by weight percentage: C: 0.38%, Si: 0.25%, Mn: 1.66%, Mo: 0.27%, V : 0.08%, Ti: 0.030%, Alt: 0.018%, P: 0.006%, S: 0.004%, N: 55ppm, H: 1.2ppm; O: 15ppm, As+Sn+Pb+Sb+Bi=0.030%, the rest is iron Fe and unavoidable The metallographic structure is uniform and fine granular bainite structure, the specification of drilling pipe: 70.2×5.05×3050mm, its performance: tensile strength Rm: 1200MPa, yield strength Rp0.2: 1020MPa, elongation A: 16% , Longitudinal impact energy AKU2 : 81J.

[0053] The manufacturing process of the present embodiment is as follows:

[0054] (1) Electric furnace smelting: Add molten iron and scrap steel to realize pre-de-P and initial composition adjustment to obtain primary molten steel, C: 0.60%, P: 0.050%, S: 0.050%;

[0055] (2) Refining in LF furnace: send the molten steel to LF furnace for refining, remo...

Embodiment 3

[0063] Example 3: The high-quality non-quenched and tempered seamless steel pipe for drilling in this example is composed of the following components by weight percentage: C: 0.37%, Si: 0.35%, Mn: 1.46%, Mo: 0.32%, V : 0.06%, Ti: 0.032%, Alt: 0.015%, P: 0.007%, S: 0.005%, N: 65ppm, H: 1.4ppm; O: 20ppm, As+Sn+Pb+Sb+Bi=0.033%, the rest is iron Fe and unavoidable The metallographic structure is uniform and fine granular bainite structure, the drilling pipe specification: 70.2×5.05×3250mm, its performance: tensile strength Rm: 1180MPa, yield strength Rp0.2: 1005MPa, elongation A: 16% , Longitudinal impact energy A KU2 : 84J.

[0064] The manufacturing process of the present embodiment is as follows:

[0065] (1) Electric furnace smelting: adding molten iron and steel scrap to realize pre-removal of P and initial adjustment of components to obtain primary molten steel, C: 0.40%, P: 0.060%, S: 0.070%;

[0066] (2) Refining in LF furnace: send the molten steel to LF furnace for re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com