Double-piston-rotor internal combustion engine

A rotor internal combustion engine, double piston technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of low output torque, high maintenance costs, large space occupation, etc., achieve low vibration and noise levels, long service life The effect of long length and large power output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

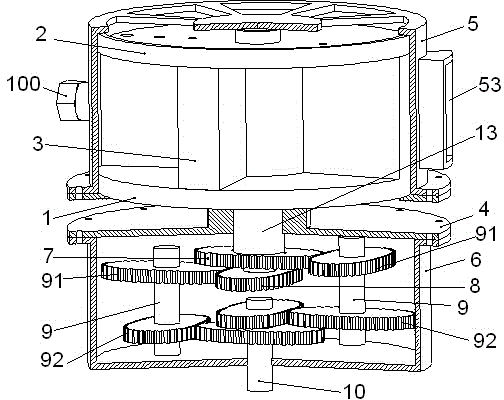

[0093] Example 1: The first technical solution of the present invention, the dual-piston rotor internal combustion engine, includes a combustion system, a transmission system, etc., see Figure 1 to Figure 14 ,as well as Figure 20 to Figure 29 .

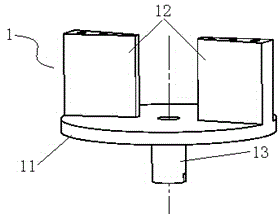

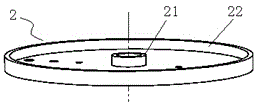

[0094] The first rotor 1 is a Y-shaped part, including a rotating shaft disk 11. One end of the rotating shaft disk 11 is two first piston bodies 12 symmetrical to the axis of the first rotating shaft 13, and the other end is provided with the first rotating shaft 13. The end of the rotating shaft 13 is provided with a keyway, the axis of the first rotating shaft 13 is provided with a shaft hole, the cover plate 2 is in the shape of a garden disc, and the cover plate 2 is also provided with some through holes corresponding to the position on the first piston body 12, The first rotor 1 and the cover plate 2 are connected and fixed by several bolts passing through the through holes of the first piston body 12 and the cover plate 2 ...

Embodiment 2

[0107] Example 2: In Embodiment 1 of the present invention, the disc-shaped member 4 can cancel the upper end disc 41 in a network structure, and retain the lower end disc 42 of the disc-shaped member 4, as well as the shaft hole provided in the middle of the lower end disc 42 and the screw holes provided around the disc surface. , so that the disk-shaped member 4 has only a single-layer disk surface. That is: the disk-shaped member 4 can be a single-layer disk surface, with a shaft hole in the middle, and screw holes on the periphery of the disk surface. The flange plate of the combustion chamber housing 5, the disc-shaped member 4 and the flange plate of the gear box 6 are fixedly connected by bolts in sequence. Others are the same as in Example 1.

Embodiment 3

[0108] Example 3: The second technical solution of the present invention, a double-piston rotor internal combustion engine, includes a combustion system, a transmission system, etc., see Figure 15 to Figure 19 .

[0109] The first rotor a1' is a Y-shaped part, one end of which is two first piston bodies a12' symmetrical to the axis of the first rotary shaft a13', and the other end is provided with a keyway. The first rotary shaft a13' of the first rotor a1' The axis is provided with a circular through hole. The second rotor a2' is a T-shaped piece, one end of which is two second piston bodies a22' that are symmetrical to the axis of the second rotary shaft a21', and the other end is provided with a keyway; the second rotary shaft a21' is sleeved on the first rotor a1' in the circular through hole. The fan angle of the first piston body a12' and the second piston body a22' are equal to the outer diameter. A circular through hole is opened in the center of the disc a4', ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com