Method for testing chromium sesquioxide in flow guiding sand by means of wavelength dispersion X-ray fluorescent spectrometry

A technology of chromium trioxide and fluorescence spectroscopy, which is applied in the field of analysis and testing of chromium trioxide content in drainage sand, can solve the problems of complex and tedious chemical titration, time-consuming and other problems, and achieve the improvement of automatic casting rate of steelmaking, Simple and fast operation, to ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] 2.1 Preparation of analytical samples

[0026] The cohesion of the drainage sand sample itself is very small, and it cannot be made into a well-formed sheet sample for X-ray fluorescence spectroscopic analysis when it is directly used for pressing, so we carried out the test of the adhesive. Commonly used solid binders include boric acid, methylcellulose, polyethylene, paraffin, starch, etc., and liquid binders include ethanol, but the commonly used reagents in steel analysis laboratories include boric acid, starch, and ethanol. Therefore, from the laboratory From the perspective of easy operation, we chose boric acid, starch and ethanol for the bonding test. From the test results can be seen from Table 3. Due to the poor cohesion of the drainage sand itself, the samples made of boric acid and ethanol cannot be molded for too long, and the samples are easily broken and decomposed, which may be difficult for the X-ray fluorescence instrument during the vacuuming process...

Embodiment 1

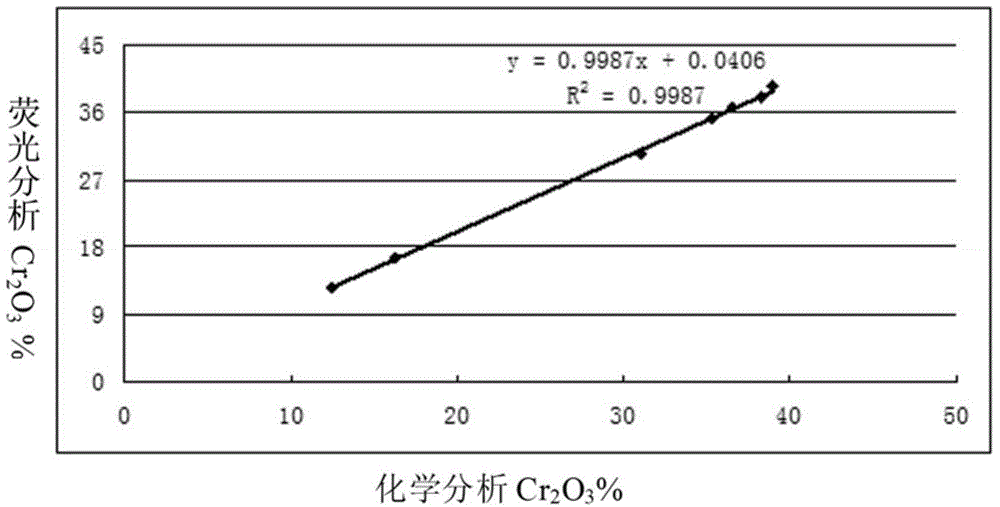

[0038] Example 1 Wavelength Dispersive X-ray Fluorescence Spectrometry Determination of Chromium Trioxide in Drainage Sand

[0039] Select a series of drainage sand production samples, and analyze according to the following method: Weigh 4.00 grams of the sample, mix 1.00 grams of starch, take the mixed sample and press it into a disc under the cake press machine, and the disc is covered with a plastic ring. Then the components were analyzed on ARL9800 fluorescence instrument.

[0040] 1. Precision test

[0041] We selected 2 samples with different contents to conduct 5 precision tests respectively, and the specific test results are shown in Table 6. It can be seen from Table 6 that the RSD of the sample is less than 0.25%, the precision is good, and it can fully meet the production requirements.

[0042] Table 6 Sample precision test (%)

[0043] Analysis times

1#

2#

1

37.82

13.38

2

37.92

13.41

3

37.66

13.41

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com