Adjustable multifunctional fractured rock mass collapse-slide testing device and use method of adjustable multifunctional fractured rock mass collapse-slide testing device

A test device and multi-functional technology, which is applied in geotechnical technology in civil engineering and earthquake disaster mitigation engineering, can solve the problems of non-disassembly, waste of resources, inconvenient assembly, etc., and achieve strong repeatability, wide adjustment range, and various functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

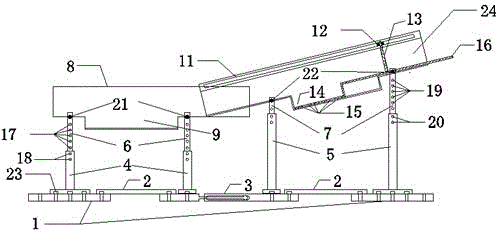

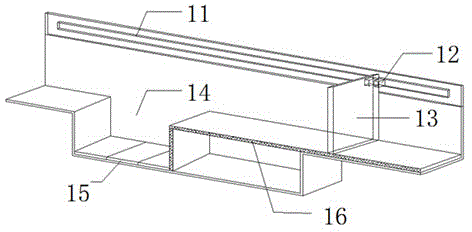

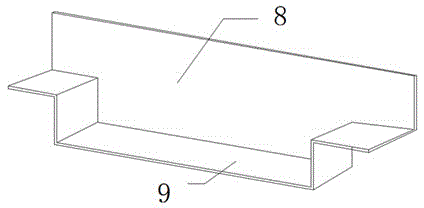

[0038] In the embodiment of the present invention, such as Figure 1-Figure 3, an adjustable multi-functional crushing rock collapse test device, comprising an accumulation belt support 4, a collapse track support 5, a telescopic rod A6, a telescopic rod B7, an accumulation belt test tank 8 and a collapse track test tank 24; The accumulation belt support 4 is provided with two holes B18 for fixing the telescopic rod A6, and the telescopic rod A6 is provided with a hole A17 for adjusting the position of the telescopic rod A6 on the accumulation belt support 4; There are two holes D20 for fixing the telescopic rod B7, and the telescopic rod B7 is provided with a hole C19 for adjusting the position of the telescopic rod B7 on the collapsed track support 5; The upper part of the telescopic rod A6 is connected by the bearing A21; the two ends of the bottom of the collapsing track test tank 24 are connected with the upper part of the telescopic rod B7 by the bearing B22; The slope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com