Tritium trap device used for removing tritium in helium-3 gas, and tritium-removing method

A gas and tritium trap technology, applied in the field of tritium trap devices, can solve the problems of difficult capture and protection of radioactive tritium, and achieve the effects of high safety, improved service life and guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

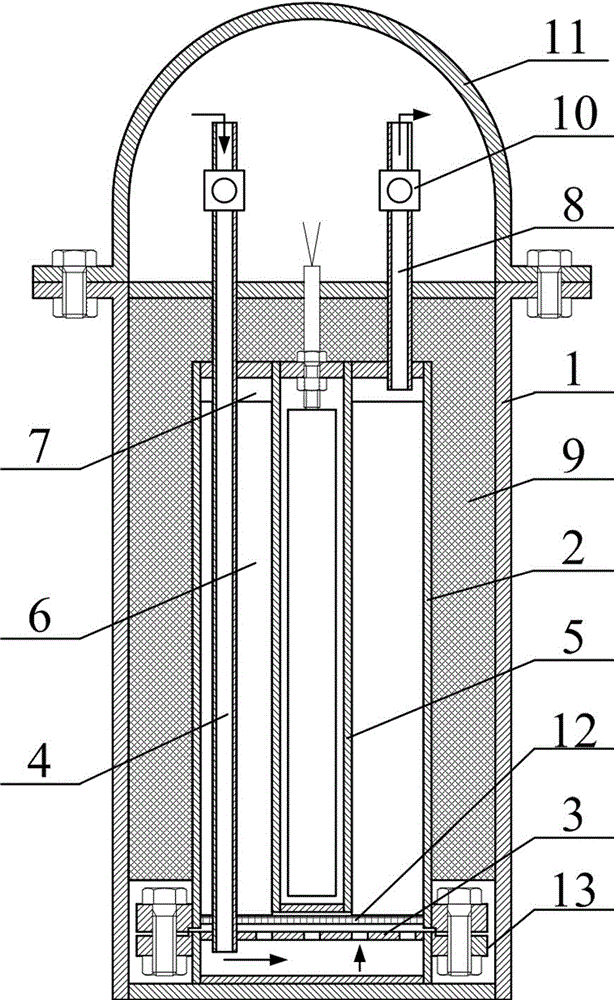

[0038] A tritium trap device for removing tritium from helium-3 gas, such as figure 1 As shown, it includes an outer shell 1, an inner shell 2 located inside the outer shell 1, an air inlet pipe 4 whose air outlet port is located below the inner shell 2, and a heating element fixed inside the inner shell 2. The cavity 5 is arranged above the gas outlet port of the inlet pipe 4 and filled with the titanium sponge 6 between the heating cavity 5 and the inner shell 2, and the titanium sponge 6 is arranged inside the inner shell 2 and is located above the titanium sponge 6 The reserved space 7, and the air outlet pipe 8 whose inlet port is located in the reserved space 7 for expansion.

[0039] Wherein, in the present embodiment, the outer shell 1 and the inner shell 2 are all arranged in a cylindrical shape, and the thickness of the titanium sponge 6 between the inner shell 2 and the heating cavity 5 is set to a thinner state, which is conducive to heating. The uniformity of tra...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that this embodiment adds some auxiliary structures to achieve better results. The specific setting method is as follows:

[0053] The space between the outer shell 1 and the inner shell 2 is set in vacuum or / and filled with insulating material 9 . That is to say, the space between the outer shell 1 and the inner shell 2 in the present invention can only be set in vacuum, or only filled with heat-insulating material 9 , and can also be filled with heat-insulating material 9 while being set in vacuum. In this embodiment, the structure between the outer shell 1 and the inner shell 2 is preferably set in a vacuum setting and filled with insulating material 9 at the same time. That is, in this embodiment, a microporous calcium silicate heat insulating layer is placed between the outer shell 1 and the inner shell 2, and a certain vacuum is drawn to increase its heat insulating effect and reduce tritium leakage. Thro...

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 or Embodiment 2 is that this embodiment optimizes the specific structural settings in the inner shell, so that the distribution of the gas passing into the titanium sponge is more uniform, and the specific settings are as follows:

[0057] In this embodiment, the inner bottom of the inner shell 2 is provided with a gas distributor 3 , and the gas distributor 3 is located below the titanium sponge 6 and above the gas outlet port of the inlet pipe 4 . A wire mesh 12 for placing the titanium sponge 6 is arranged above the gas distributor 3 .

[0058] The gas outlet port of the air inlet pipe 4 extends from the top of the outer shell 1 into the inner shell 2 and penetrates the titanium sponge 6 from the top of the inner shell 2 and then extends to the bottom of the gas distributor 3 .

[0059] After the helium-3 gas in the present invention is distributed by the gas distributor 3, it is effectively and evenly dispersed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com