Sulfur-doped carbon nanotube Pt-loaded catalyst for direct methanol fuel cell and preparation method of catalyst

A methanol fuel cell, carbon nanotube technology, applied in battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

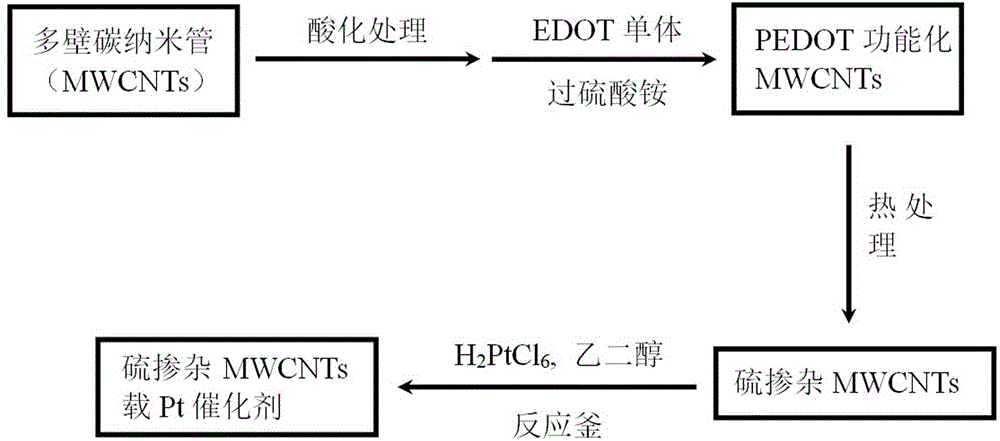

[0017] Such as figure 1 Shown, a kind of preparation method of direct methanol fuel cell sulfur-doped carbon nanotube loaded Pt catalyst, comprises the steps:

[0018] 1) Add 20 mg of acidified multi-walled carbon nanotubes (MWCNTs), sodium dodecyl sulfate (SDS) and 20–300 μL of 3,4-ethylenedioxythiophene (EDOT) in a container filled with triple distilled water. body, stirred at room temperature for 2 hours and then added 5 mg mL dropwise ?1 of (NH 4 ) 2 S 2 o 8 aqueous solution, and then continuously stirred for 24 hours, and the resulting product was centrifuged, washed and vacuum-dried to obtain a PEDOT functionalized MWCNTs composite material;

[0019] 2) PEDOT functionalized MWCNTs composite samples were placed in a tube furnace for heat treatment for 3 hours under nitrogen protection to obtain sulfur-doped MWCNTs composites;

[0020] 3) Add sulfur-doped MWCNTs with a mass ratio of Pt / sulfur-doped MWCNTs = 1 / 4 and 19.3 mM H in 20 mL of ethylene glycol 2 PtCl 6 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com