MCFC hybrid power system capable of regulating CO2 recovery rate and operation method

A technology of compound power and recovery rate, which is applied to machines/engines, fuel cell parts, fuel cells, etc., can solve the problems of decreased efficiency and low power generation efficiency, and achieve the effect of improving power generation efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

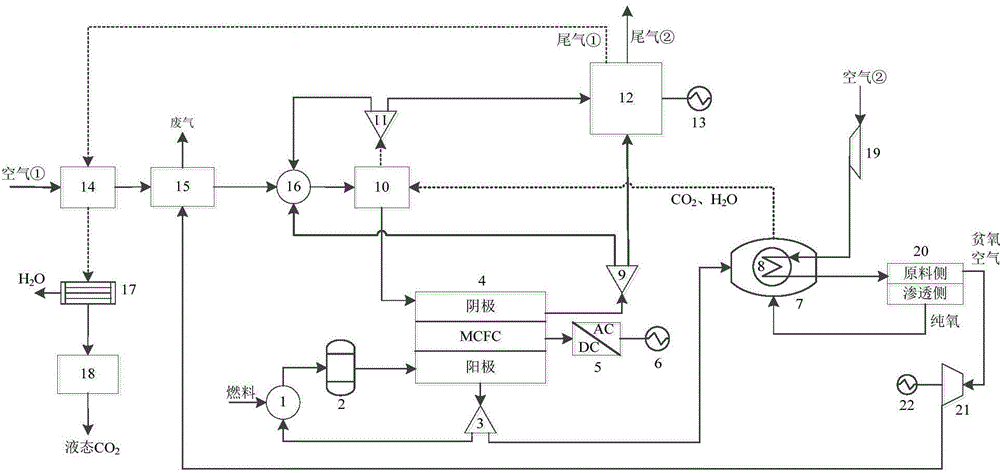

[0026] The invention provides an adjustable CO 2 The MCFC compound power system and operation method of recovery rate will be further described below with reference to the drawings and specific embodiments.

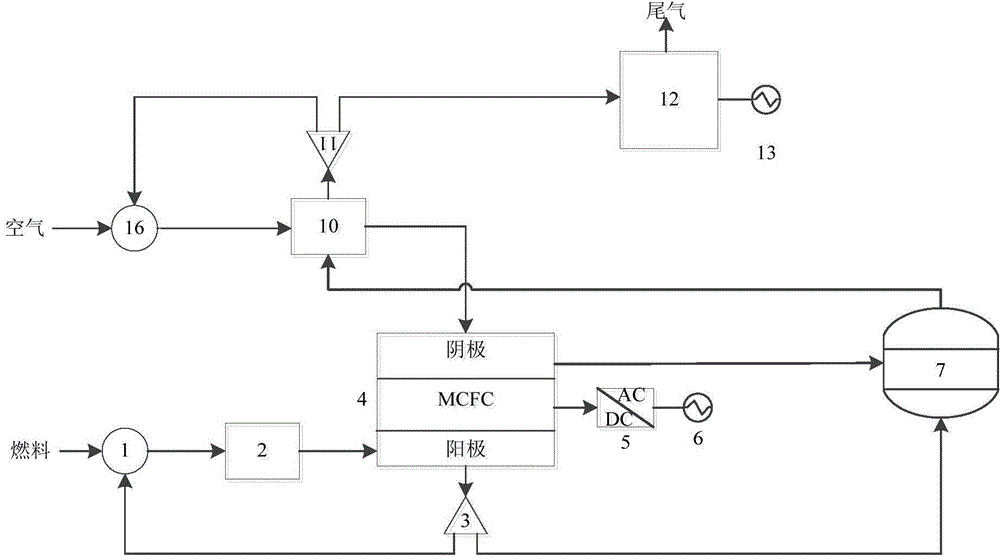

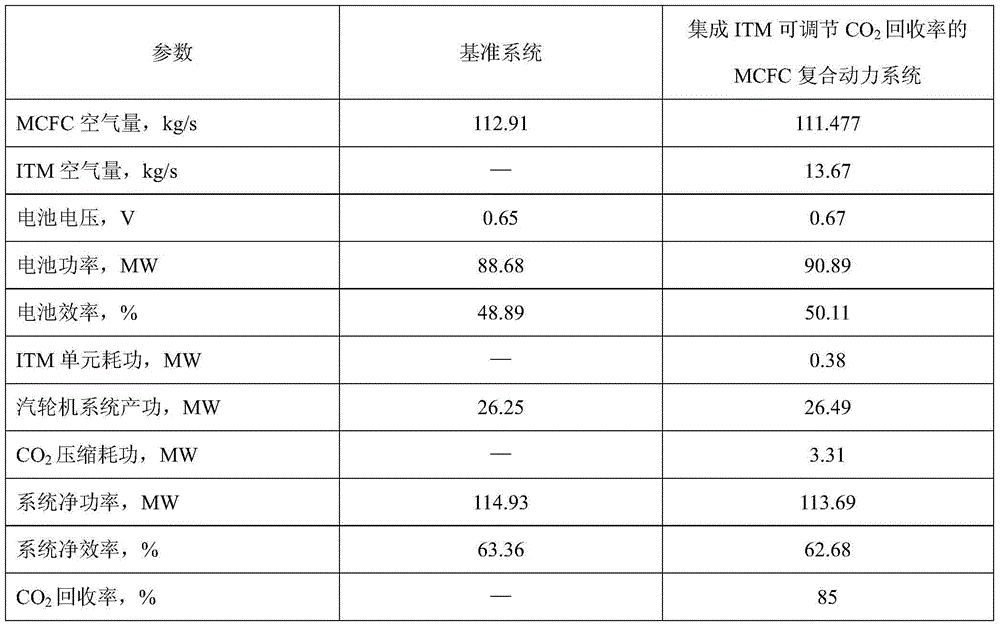

[0027] The benchmark system does not recover CO 2 System, its structure diagram such as figure 1 Shown. The fuel and the recycled part of the anode exhaust are mixed in the first mixer 1 and then enters the pre-reformer 2 for reforming, and then enters the anode of the MCFC stack 4, and the air and the recycled part of the afterburner exhaust are mixed in the second After mixing, the reactor 16 is preheated by the second heat exchanger 10, and then enters the cathode of the MCFC stack 4, where an electrochemical reaction occurs in the stack, and the DC / AC converter 5 and the first generator 6 output electrical energy. After that, the anode exhaust is divided into two paths by the first separator 3: one is circulated back to the first mixer 1 to preheat the fuel and prevent r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com