Deep processing method of low-value marine fish leftover protein hydrolysis fluid

A technology of protein hydrolyzate and seawater fish, which is applied in deodorization, can solve the problems of high content of biogenic amines and heavy metals, heavy fishy smell, deep color of fish protein hydrolyzate, etc., to protect nutrition and active ingredients, avoid poisoning, and improve the treatment process Gentle and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

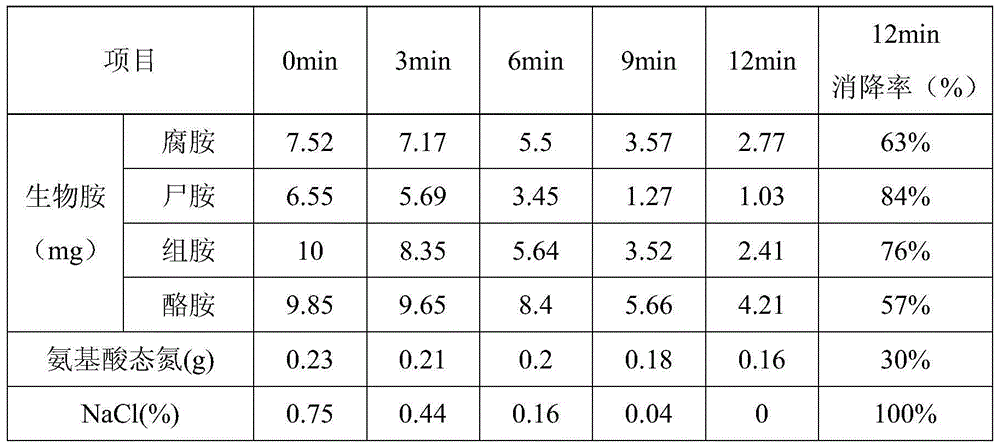

Embodiment 1

[0021] Take tuna scraps frozen at -80°C and thaw in a 4°C refrigerator. The thawed fish was crushed with a beater, mixed evenly and then sampled. Mix the pulverized leftovers with water at a solid-to-liquid ratio of 1:3, and adjust the pH of the supernatant to 8 with 2N HCl or 2N NaOH. Heat and stir the feed liquid and control the temperature of the feed liquid to be 50°C. Add trypsin to the feed liquid while stirring, the addition amount is 2500U / g, and hydrolyze for 5h. Use 2N HCl or 2N NaOH solution to adjust the pH of the above hydrolyzate to 3, put it into a constant temperature stirring device, set the heating temperature to 70°C, and when the temperature of the enzymatic hydrolyzate reaches 70°C, add 3% activated carbon and continue stirring at constant temperature for 1h. Activated carbon was removed by suction filtration to obtain a decolorized solution. The decolorization rate of the enzymolysis solution was measured to be 90%; using GC / MS to detect and compare th...

Embodiment 2

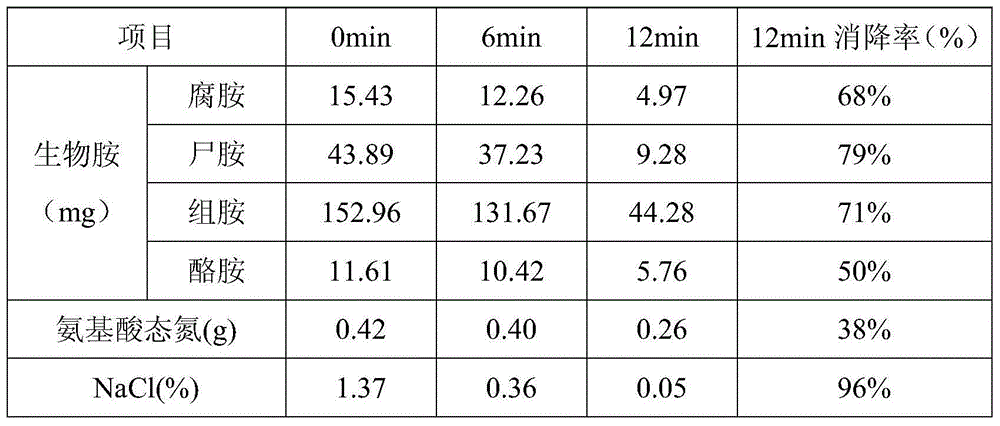

[0027] Take the offal of Qingzhan fish frozen at -20 ℃, and put it in the refrigerator at 4 ℃ to thaw. The thawed fish was crushed with a beater, mixed evenly and then sampled. The pulverized leftovers were mixed with water at a solid-liquid ratio of 1:4, and the pH of the supernatant was adjusted to 7.8 with 2N HCl or 2N NaOH. Heat and stir the feed liquid and control the temperature of the feed liquid to be 55°C. Add trypsin to the feed liquid while stirring, the addition amount is 2000U / g, and hydrolyze for 4.5h. Use 2N HCl or 2N NaOH solution to adjust the pH to 4, put it into a constant temperature stirring device, set the heating temperature to 80°C, when the temperature of the enzymolysis solution reaches 80°C, add 4% activated carbon, and continue stirring at constant temperature for 1h. Activated carbon was removed by suction filtration to obtain a decolorized solution. The measured decolorization rate of the enzymolysis solution was 93%; using GC / MS to detect and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com