Method for preparing chilli seed oil and chilli seed dietary fibers

A technology of chili seed oil and dietary fiber, which is applied in the field of food processing, can solve the problems of limitation, waste of nutritional resources, low utilization rate, etc., and achieve the effects of increasing added value, protecting nutrition, and extending the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: method of the present invention (ultrahigh pressure combined with enzyme method)

[0021] (1) Put 40-60 mesh pepper seeds into a 50mL PE plastic bottle, add hexane at a ratio of 1:10, seal it and put it in an ultra-high pressure equipment container, add 1% alkaline protease (2000U / g bottom Substance)+cellulase (2000U / g substrate) (W / W=3:2), 45°C, 450Mpa treatment for 5min; then at 4°C, 3500r / min low temperature centrifugation for 10min, desolvation; obtained under this condition The chili seed oil is clear, transparent, free of impurities and solvent residues, and the extraction rate of the chili seed oil is 98.21%.

[0022] (2) Add distilled water to the pre-precipitated seed meal according to the solid-to-liquid ratio (in W / V) of 1:10, react at 45°C for 1 hour, centrifuge at 4°C and 3500r / min for 10min at low temperature, and remove the supernatant Precipitate with 5 times the volume of 95% ethanol, desolventize and freeze-dry to obtain soluble dietary ...

Embodiment 2

[0023] Embodiment 2: method of the present invention (ultrahigh pressure combined with enzyme method)

[0024] (1) Put 20-40 mesh chili seeds into a 50mL PE plastic bottle, add hexane at a ratio of 1:12, seal it and put it in an ultra-high pressure equipment container, add 1% alkaline protease (2000U / g bottom Substance) + cellulase (2000U / g substrate) (W / W=3:2), at room temperature, 150Mpa treatment for 5min; then at 4°C, 3500r / min low temperature centrifugation for 10min, precipitation; obtained under this condition The chili seed oil is clear, transparent, free of impurities, and has no solvent residue, and the extraction rate of the chili seed oil is 67.69%.

[0025] (2) Add distilled water to the pre-precipitated seed meal according to the solid-to-liquid ratio (in W / V) of 1:10, react at 45°C for 1 hour, centrifuge at 4°C and 3500r / min for 10min at low temperature, and remove the supernatant Precipitate with 5 times the volume of 95% ethanol, desolventize and freeze-dry t...

Embodiment 3

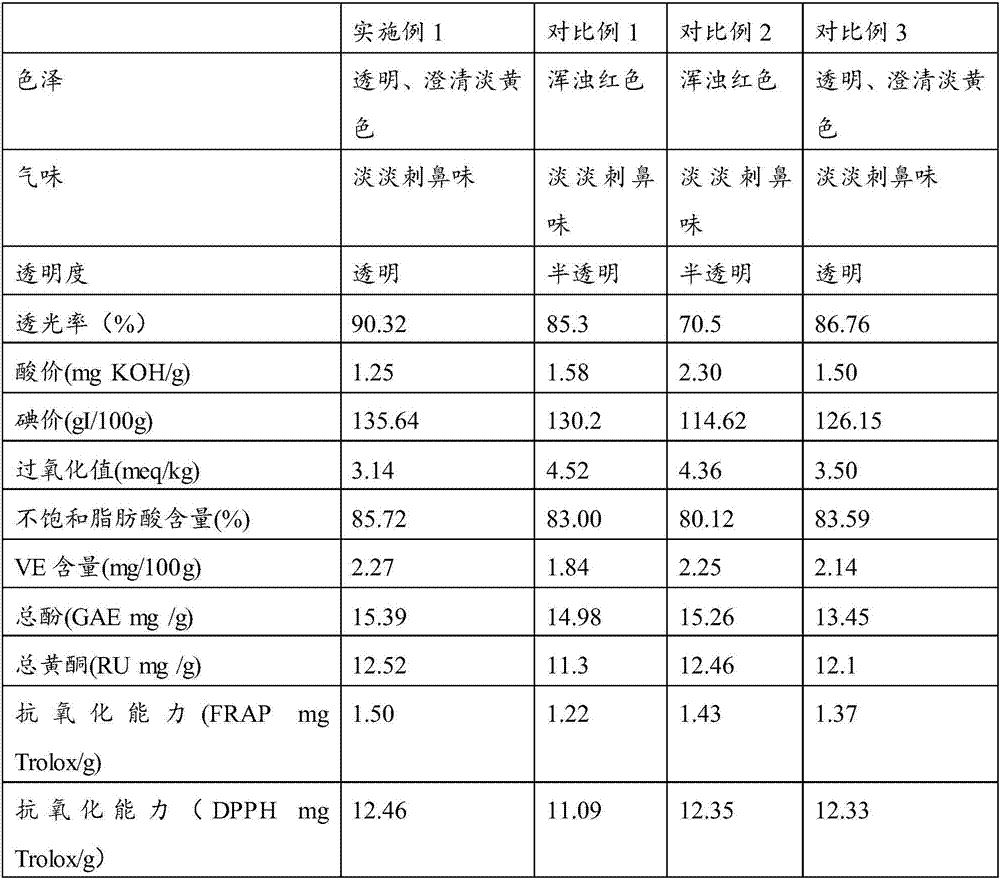

[0036] Embodiment 3: the contrast of capsicum seed oil

[0037] The ultrahigh pressure combined with enzymatic treatment of embodiment 1 and comparative example 1-3, ultrahigh pressure combined with chemical method treatment, ultrahigh pressure treatment and enzyme treatment capsicum seed oil main quality change are measured: measurement index includes color and luster, smell, transparency, Determination of light transmittance, refractive index, acid value, iodine value, saponification value, peroxide value, vitamin E, fatty acid and antioxidant activity. The quality in the above method is shown in the table below:

[0038] Table 1 Quality testing results of pepper seed oil by different methods

[0039]

[0040]It can be seen from the above table that compared with different treatments, the comprehensive quality of the capsicum seed oil after the ultra-high pressure combined with enzyme treatment of the present invention is obviously better than the capsicum seed oil after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com